Pennant Pool Heater

Page 13

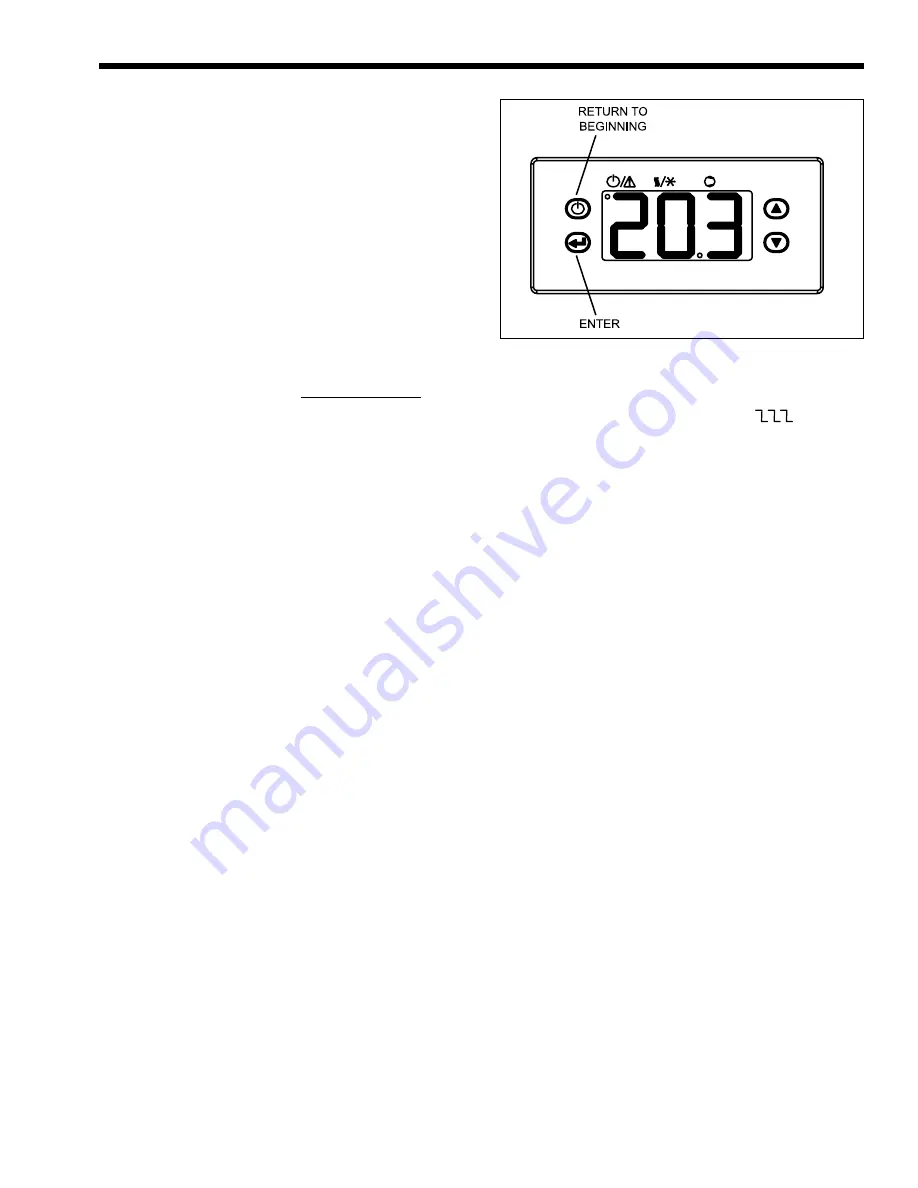

Figure 6). The LCD screen will display the pool loop

return temperature during normal operation. When the

control is first powered up, it displays

. It then

displays the temperature at the pool loop sensor. After

the temperature is displayed, the current settings

(parameters) may be viewed. To scroll through the

parameters, press the down arrow button to advance to

the next parameter.

5.3.2 Programming Control Parameters

There are thirteen (13) control parameters. Only

three (3) of those should be set, LSP, dLS and Pd. The

remaining parameters are factory set and should not be

changed.

The pool loop temperature (desired pool

temperature) is set by changing the LSP parameter.

After scrolling through the parameters until LSP is

displayed, press the enter button. The setpoint will be

displayed. Press the up arrow or down arrow buttons

until the desired setpoint is displayed. Press the enter

button and the setpoint will be activated. The display

will return to indicating the present pool loop

temperature.

In addition to the ability to set the pool loop

temperature, the differential associated with that

setting may also be adjusted. The differential is set by

changing the dLS parameter. After scrolling through

the parameters until dLS is displayed, press the enter

button. The setpoint will be displayed. Press the up

arrow or down arrow buttons until the desired setpoint

is displayed. Press the enter button and the setpoint

will be activated. The display will return to indicating

the present pool loop temperature.

The last parameter that may be adjusted is Pd,

the pump off delay. After again scrolling through the

parameters until Pd is displayed, press the enter

button. The pump delay time will be displayed. The

pump off delay may be set between 0.1 and 10

minutes. Press the up arrow or down arrow buttons

until the desired setpoint is displayed. Press the enter

button and the setpoint will be activated. The display

will again return to indicating the present pool loop

temperature.

Figure 6. Pool Heater Controller.

5.1 Main Power

Pennant appliances are fitted with pigtail leads

for main power connection. Connect a fused 15-

ampere, 120-volt supply to the black wire. Neutral leg

is connected directly to the white wire. Ground wire is

connected to the green wire.

Wiring diagrams are shown in Section 10 in

Figures 12 through 15. Field wiring is shown in

Section 10 in Figures 16 and 17.

IMPORTANT NOTE: If the backwash operation is

manual the heater must be shut off manually during

backwashing.

Auxiliary Time Clock Wiring:

If a time clock is used to control the pool filter

pump operation, a separate switch or relay must be

used to shut off heater at least 15 minutes before the

filter pump is shut off. Wire the switch or relay to the

field-wiring board’s “Other Ints” terminals. Wire the

switch or relay to the field-wiring board’s “Other Ints”

terminals, after removing the factory-installed jumper.

All field-installed electrical safety devices and

field-installed controllers can be connected in series to

the Pennant’s “Other Ints” terminals on the field-

wiring board (remove the factory-installed jumper).

5.2 Temperature (Operating) Control

The Pennant temperature control operates by

measuring the pool loop return temperature, before the

heater inlet piping. It is adjustable to a maximum of

104° F and will prevent heater operation at return

temperatures above 104° F. It also controls the pool

heater pump and the temperature of the water entering

the heat exchanger. It also controls the Pennant pump

operation and the mixing system, which tempers the

water entering the heat exchanger to prevent damage

from condensation. The sensors for the control are

installed as shown in Figure 5 and Section 4.3, Sensor

Locations. The automatic mixing system sensor,

already installed, is shown in Figure 4. During

operation, the automatic mixing system diverts water

from the outlet to the inlet to “pre warm” the water to

a minimum inlet temperature of 120°F. This prevents

condensation from forming, which can damage the

heater.

5.3 Programming the Temperature

Control

5.3.1 Temperature Control Overview

The digital display on the control has the

following uses:

•

To display the actual pool loop temperature

during normal operating mode.

•

To allow the user to view and adjust the

control settings.

Figure 6 identifies the control buttons.

The Pool Heater Temperature Control face

contains an LCD screen and four (4) buttons (see

Summary of Contents for Pennant PNCP

Page 27: ...Pennant Pool Heater Page 27 Figure 9 Sheet Metal Components...

Page 31: ...Pennant Pool Heater Page 31 Figure 13 Pennant 1250 2000 Ladder Diagram...

Page 32: ...LAARS Heating Systems Page 32 Figure 14 Pennant 500 1000 Wiring Schematic...

Page 33: ...Pennant Pool Heater Page 33 Figure 15 Pennant 1250 2000 Wiring Schematic...

Page 34: ...LAARS Heating Systems Page 34 Figure 16 Field Wiring PNCP 500 1000...

Page 35: ...Pennant Pool Heater Page 35...