3

Introduction

Welcome to the Bottle top dispenser User Manual. Users should read this manual carefully,

follow the instructions and procedures, and beware of all the cautions when using this

instrument.

Warranty

This instrument is warranted for a period of 12 months from the date of invoice. All warranties

are null and void if the product has been misused, modified or repaired by unauthorised

personnel, if the defects are caused by negligence (instruction manual, maintenance) or by

normal wear and tear. Use only original manufacturer’s accessory/spare parts.

Delivery

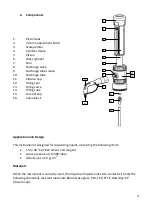

This unit is supplied with 1 x main unit, user manual, discharge tube, mounting tool, filling tube

and adapters of PP of the following sizes:

Nominal vol. tube

Adapter, PP

Filling

0.5 – 5, 1 – 10, 2.5 – 25, 5 - 50

GL 25, GL 28, GL 32,GL 38, S40

220 mm

1.

Safety Instructions

This instrument may be used with approved hazardous materials (refer to chemical

compatibility chart), operations, and equipment. This manual does not purport to address all

of the safety problems associated with its use. It is the responsibility of whoever uses this

instrument to consult and establish appropriate safety and health practices and determine the

applicability of regulatory limitations prior to use.

a.

Follow the general instructions for hazard prevention and safety regulations, e.g., wear

protective clothing, eye protection and gloves.

b.

Observe the reagent manufacturer’s information.

c.

Every user must be acquainted with this Operating Manual before operation.

d.

Use the instrument only for dispensing liquids, with strict regard to the defined Operating

Exclusions and Limitations. If in doubt, contact the manufacturer or supplier.

e.

When dispensing, the discharge tube must always point away from the user or any other

person. Avoid splashes. Only dispense into suitable vessels.

f.

Never carry the mounted instrument by the cylinder sleeve or the valve block. Breakage

or loosening of the cylinder may lead to personal injury from chemicals.

g.

Never press down the piston when the closure cap is pushed on.

h.

Never remove the discharge tube while the cylinder is filled.

i.

Use smooth gentle movements to operate the piston upwards and downwards.

j.

Use only original manufacturer’s accessories and spare parts. Don't carry out technical

modifications.

k.

Before using check the instrument for visual damages. In case of trouble (e.g., piston

difficult to move, sticking valves or leakage), immediately stop dispensing. Clean the

instrument according to the cleaning instructions.

Summary of Contents for 550.001.305

Page 16: ...16...