4

2.

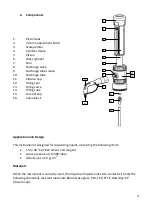

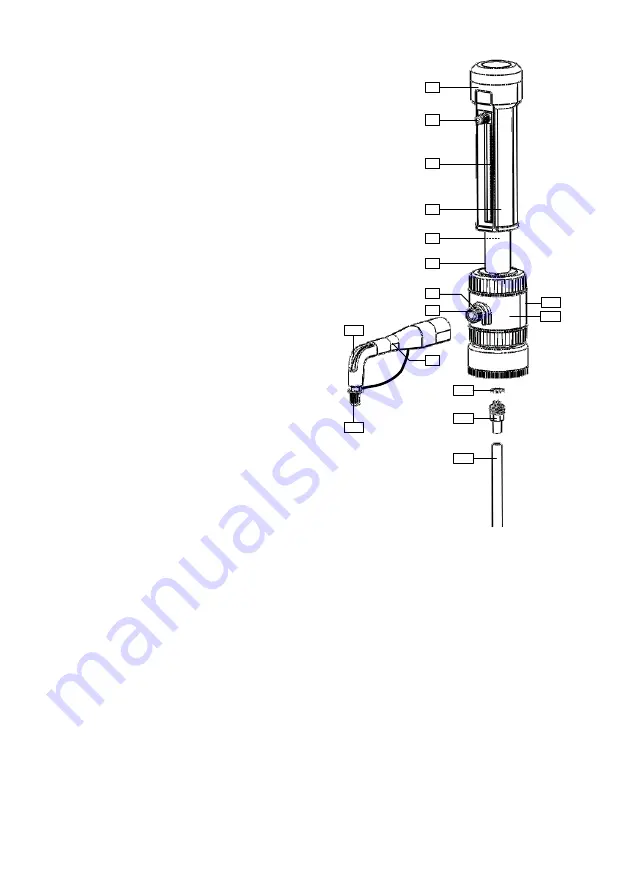

Components

1.

Piston seat

2.

Volume adjustment knob

3.

Scale pointer

4.

Cylinder sleeve

5.

Piston

6.

Glass cylinder

7.

Seal

8.

Discharge valve

9.

Discharge tube sleeve

10.

Discharge tube

11.

Closure cap

12.

Filling seal

13.

Filling valve

14.

Filling tube

15.

Air vent cap

16.

Valve block

1.

2.

3.

4.

7.

8.

9.

11.

10.

12.

13.

14.

5.

6.

15.

16.

Application and Design

This instrument is designed for dispensing liquids, observing the following limits:

15 to 40 °C of instrument and reagent

vapor pressure up to 500 mbar

density up to 2.2 g/cm

3

Materials

When the instrument is correctly used, the dispensed liquid comes into contact with only the

following chemically resistant materials: Borosilicate glass, PFA, FEP, PTFE, Hastelloy; PP

(closure cap).

Summary of Contents for 550.001.305

Page 16: ...16...