Chapter 2: Prerequisites

Product Service 1-800-522-7658

4

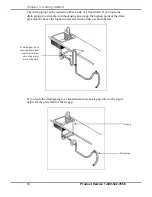

inlet valve on the washer is equipped with a plastic hose barb connection to

accommodate .375

"

(9.53 mm) ID flexible plastic or rubber hose. Use a spring or

band hose clamp to secure the hose to the hose barb connection. The hose barb

connection may be removed from the valve to expose a male 3/4

"

- 11-1/2 NH

hose coupling. Rigid plastic, tin-lined, or stainless steel tubing and fitting can be

connected to the washer fitting.

An optional Connection Kit (Labconco P/N 4592200) is available for connecting

.375" (9.53mm) OD plastic tubing to the purified water inlet valve. The purified

water system connections must be airtight to prevent the washer pump from

pulling air instead of water.

If the purified water is stored in a carboy, at least 3.4 gallons (13 liters) must be

available for each rinse. If all the purified water is not available at the start of a

wash cycle, but instead is produced concurrently with the wash cycle, the

production rate must permit at least 0.9 gallon (3.4 liters) per minute to be

delivered to the washer.

Electrical Requirements

The Glassware Washer should be hard-wired directly into a junction box using

conduit. A 20 Amp circuit breaker or fuse is required.

The Glassware Washer is designed to operate at 230 VAC, single phase. It will

operate safely at nominal 208 VAC, however the heater output will be

significantly degraded as the operating voltage drops below 230V. It is highly

recommended that if the voltage is low that a boost transformer is used.

Drain Requirements

The drain hose, .75" (1.9 cm) ID is installed during manufacture. The hose

provides a flexible coupling to the building drain piping and can be secured with a

spring or band hose clamp. (A band hose clamp is provided with the washer.)

Tubing or pipe, .75

"

(1.90 cm) ID or larger, should be provided for the building

drain. The use of an air gap is strongly recommended to prevent siphoning of

wastewater into the washer.

Do not reduce the size of the drain plumbing.