24

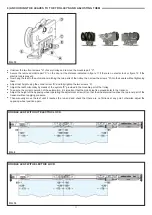

PART DESCRIPTION

LED

DL1 (40V)

= shows the presence of the 24V voltage at the output of the switching power supply.

DL2 (E2) - DL3 (E1) - DL4 (E3) = display the signals coming from the encoder sensor.

DL6 ‑ DL7

= battery status

Buzzer BZ1

= audible warning device.

MP1

= microcontroller A.

PS1

= START button. Controls door opening.

S1

= dip switch 1:

selection of the automation number

1 OFF = AUTOMATION "1"

1 ON = AUTOMATION "2" (only in case a single digital selector ET-DSEL is used to control two

automatic doors)

•

CONNECTOR J12

: Battery charge card connection.

•

CONNECTOR J5

: Battery connection.

•

CONNECTOR J8

: EN/RF1 radio receiver connector.

•

CONNECTOR J6

: Motor-encoder wiring connection.

•

CONNECTOR J4

: Electric lock 1 wiring connection (LOCK1). Black solenoid cables.

•

CONNECTOR J3

: Electric lock 2 wiring connection (LOCK2). Red solenoid cables.

•

CONNECTOR J2

: Optional UR24 module connection (OUT1).

•

CONNECTOR J1

: Optional UR24 module connection (OUT2).

•

JUMPER J10

:

selection of the operation of the LOCK2 electric lock output.

POSITION 1 = PHARMACY function (F04 = ON) or anti‑roll function for boats (P26 = 01%)

POSITION 2 = BISTABLE "EBSBIS" electric lock.

•

CONNECTOR J11

: Connection of digital selector T-NFC

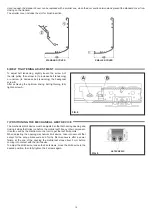

ELECTRIC CONNECTION DESCRIPTION

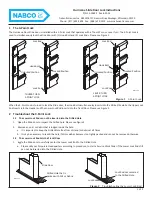

On the plastic side caps of the automation ETERNA 150 (part 1 in figure in para. 3) there is a knockout hole, through which

the electric cables must be inserted.

Along the upper part of the aluminium transom, there are various plastic cable guides (part 8 in the figure in para. 3) inside

which the cables should be run.

The installer must prepare suitable cable guides on the side cap of the automation control unit for the passage of the

cables and ensure wire stability inside the automation control unit prior to the start‑up of the automatic door, in order to

prevent any contact between the electric cables and the moving parts of the automation.

•

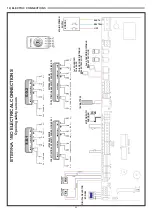

TERMINAL BOARD M1 (F-N-GROUND)

230Vac 50‑60Hz mains supply;

phase at terminal F, neutral at terminal N, ground connection at terminal

.

Ground the automation by connecting the ground cable from the line to faston

connectors on the aluminium transom.

Then, using the specific cable, connect the second ground faston on the transom to

the ground terminal onboard the electronic control unit ET-LOGIC-B.

The line is protected by the F1 2.5A fuse.

On the power supply mains, provide an omni-polar switch/cut off device with contact

opening distance of at least 3 mm.

The power supply line must be protected against short circuit and leakage to ground.

Separate the 230Vac power supply line from the very-low voltage line control unit

relative to control and safety accessories.

•

TERMINAL BOARD M3 (Power supply of external accessories)

24Vdc output for power supply to accessories (radars and sensors).

Max. load 500mA.

22

= Positive te24V.

21

= Negative terminal 0.

The presence of the output voltage is displayed by the Led DL1.

20

= TEST terminal for safety sensors preset with test function.

SAFETY

SENSORS TESTS

SENSORS POWER SUPPL

Y