5

2000

2500

3000

3500

4000

4500

5000

5500

6000

6500

949

1199

1449

1699

1949

2199

2449

2699

2949

3199

516,5

641,5

766,5

891,5

1016,5

1141,5

1266,5

1391,5

1516,5

1641,5

1575

1950

2325

2700

3075

3450

3825

4200

4575

4950

400

345

345

345

345

345

345

345

345

345

345

400

400

400

400

400

400

400

400

400

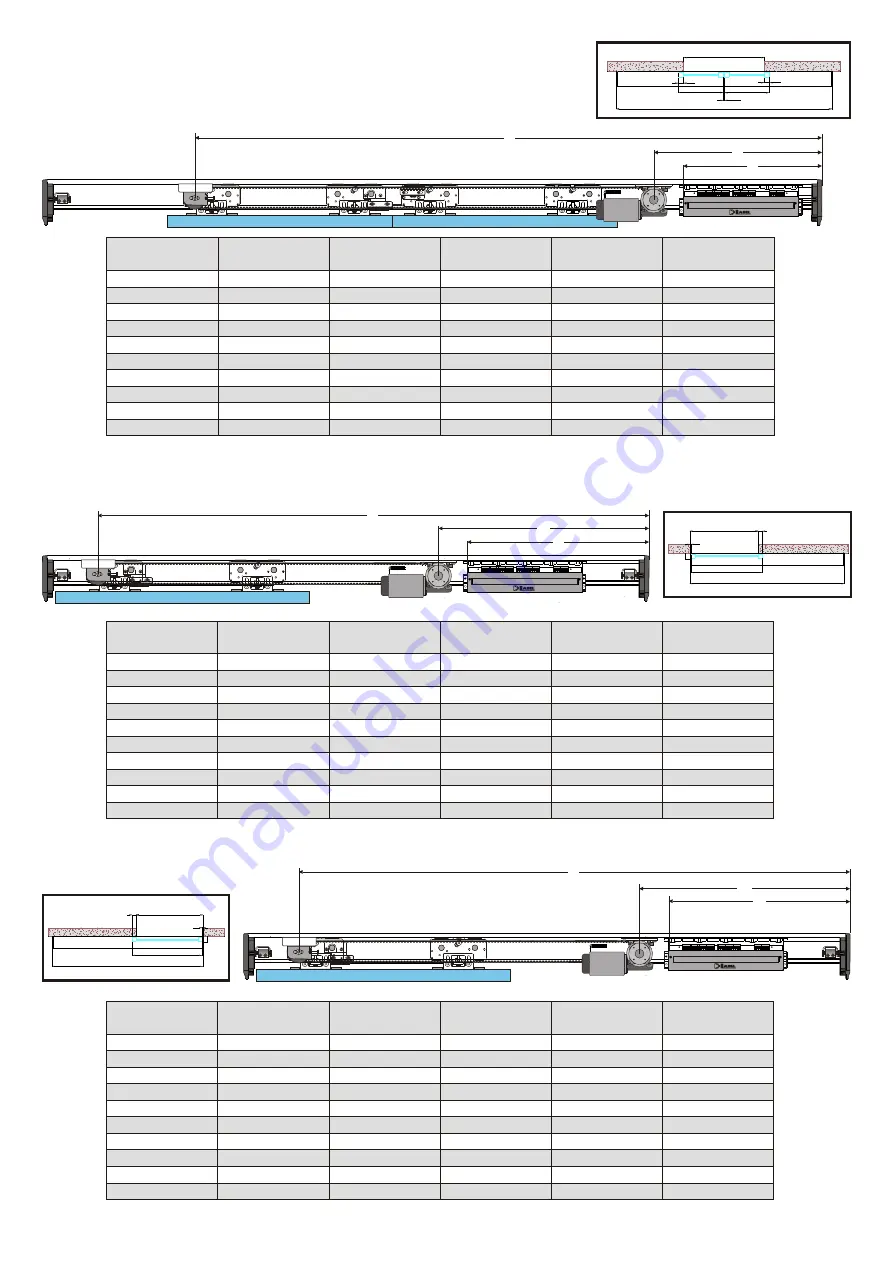

SINGLE DOOR RH LEAF

WITHOUT ELECTRIC LOCK

SINGLE DOOR LH LEAF

WITHOUT ELECTRIC LOCK

DOUBLE DOOR LEAF WITHOUT ELECTRIC LOCK

TRANSOM LENGTH LT

LT=2PL-B+2S+24

FREE PASSAGE PL

PL=(LT+B)/2-S-6

LEAF WIDTH LM

LM=(LT-B)/4+S/2-6

IDLE PULLEY F

LT*3/4+75

MOTOR M

CONTROL UNIT C

2000

2500

3000

3500

4000

4500

5000

5500

6000

6500

968

1218

1468

1718

1968

2218

2468

2718

2968

3218

1008

1258

1508

1758

2008

2258

2508

2758

3008

3258

1913

2413

2913

3413

3913

4413

4913

5413

5913

6413

650

595

845

1095

1345

1595

1845

2095

2345

2595

2845

900

1150

1400

1650

1900

2150

2400

2650

2900

TRANSOM LENGTH LT

LT=2PL-B+S+24

FREE PASSAGE PL

PL=(LT+B-S)/2-12

LEAF WIDTH LM

LM=(LT-B+S)/2-12

IDLE PULLEY F

LT-87

MOTOR M

LT-LM-342

CONTROL UNIT C

LT-LM-397

S

LT

PL

B

LM

S

S

B

LM

LM

PL

LT

S

LT

PL

B

LM

F

M

C

F

M

C

M

C

F

2000

2500

3000

3500

4000

4500

5000

5500

6000

6500

968

1218

1468

1718

1968

2218

2468

2718

2968

3218

1008

1258

1508

1758

2008

2258

2508

2758

3008

3258

1913

2413

2913

3413

3913

4413

4913

5413

5913

6413

650

595

845

1095

1345

1595

1845

2095

2345

2595

2845

900

1150

1400

1650

1900

2150

2400

2650

2900

TRANSOM LENGTH LT

LT=2PL-B+S+24

FREE PASSAGE PL

PL=(LT+B-S)/2-12

LEAF WIDTH LM

LM=(LT-B+S)/2-12

IDLE PULLEY F

LT-87

MOTOR M

LT-LM-342

CONTROL UNIT C

LT-LM-397

FIG.3

FIG.4

FIG.5

Summary of Contents for EVOLUS

Page 2: ......