35

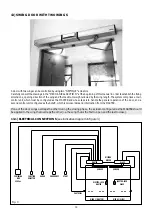

18) ADVANCED FUNCTIONS - TECHNICAL MENU

The adjustments in the technical menu allow you to change the various door operating parameters.This is of use when the

default settings are not the optimal ones.

digital selector must be available for access to the TECHNICAL MENU.

enter the program from digital selector, turn the key to the horizontal

function locking

position, press the two keys

and , and keep them depressed, then turn the key back to the vertical

work position.

The yellow leds will come on in sequence from left to right, showing that data are being loaded. After this, the red battery led and

the yellow led of photocell 3 will come on.

The digital selector will now be operating on dip-switch 1 of switch S1, thus in the adjustment phase described in section 6.

Press the

SET

key 11 times to go to the end of the basic regulazione described in sect. 8 of the main instructions, i.e. the closing

stroke strength (TM10).

This situation coincides with the beginning of the TECHNICAL MENU;

Press the SET button once to access the point 1 adjustment option:

simularly to the previous adjustments, the yellow leds form a scale that indicates the value entered.

Press the key to decrease or the key to increase this value.

1) PUSHING FORCE AT THE BEGINNING OF THE CLOSING MANOEUVRE

Press the SET key to access the point 2 adjustment option.

2) PUSHING DISTANCE AT THE BEGINNING OF THE CLOSING MANOEUVRE

Press the SET key to access the point 3 adjustment option.

3) NOT USED

Press the SET key to access the point 4 adjustment option.

4) NOT USED

Press the SET key to access the point 5 adjustment option.

F1

F1

This is the pushing force at the beginning of the closing manoeuvre that helps the door to start

moving when the force of the spring alone is unable to provide sufficient force on start-up.

Increase the value to obtain a higher pushing power.

This is the initial part of the closing manoeuvre in which the pushing power described in the previous

point 1 is provided. It helps the door to begin moving on start-up.

Increase the value to obtain a greater distance between the starting point on closing and the point

in which the pushing power ceases.

Summary of Contents for NEPTIS/LE

Page 4: ...MECHANICAL SECTION NEPTIS LE 550 110 120 Nepti N e p t i S ...

Page 14: ...notes ...

Page 15: ...ELECTRONIC SECTION NEPTIS LE Nepti N e p t i S ...

Page 38: ...notes ...

Page 39: ......