28

Partial opening

, is used only in a double leaf door automation

To activate the partial opening press briefly the button

;

The symbol on the display indicates that the function is on.

In a dual leaf door, only the first leaf (Master) opens if the opening command is given from the

internal or external radar inputs.

Partial opening only operates in bi-directional, unidirectional, and open door automatic programs.

To disable partial opening, press again briefly the button

.

For details, refer to paragraph "Dual leaf swing door".

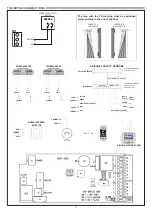

F2

Disabling the step-by-step operation (if F40 = ON)

Briefly press the button F2 to disable the step-by-step operation previously enabled by setting

F18 ON (see the paragraph "Functions settings") and enable the automatic closing of the door.

Press again button F2 in order to enable the step-by-step operation.

The symbol F2 on the display disappears.

F1

Door opening command

Press the button F1 to open the door, but only in bi-directional and unidirectional programs (if

function F32 OFF).

Press F1 to open the door in all operating programs, both automatic and night lock (if function

F32 ON).

F3

It is used only in a MASTER / SLAVE double leaf door automation

In the main screen of the work program, the button F3 has no operating function. Its function

is just to toggle from MASTER to SLAVE and ensure the proper communication between the

automations and the selector ET‑DSEL.

M is displayed on the top right of the display when you select the Master automation, while S is

displayed when you select the Slave automation.

When the operation is correct, the work program of the door both in M and in S is displayed,

otherwise in the event of communication fault, it is displayed "NO SIGNAL" related to the

automation that is not working properly.

"SCHEDULED MAINTENANCE" message

If the display shows the message "SCHEDULED MAINTENANCE", contact the authorized

service centre to request the service visit on the system.

Operation of other buttons located on the panel of the program selector ET-DSEL