LM1012TTS Table-Top Label Applicator System

USER'S MANUAL

Made in the U.S.A.

© 2022 LABELMILL

01/01/2022 Model LM1012TTS

Page 14

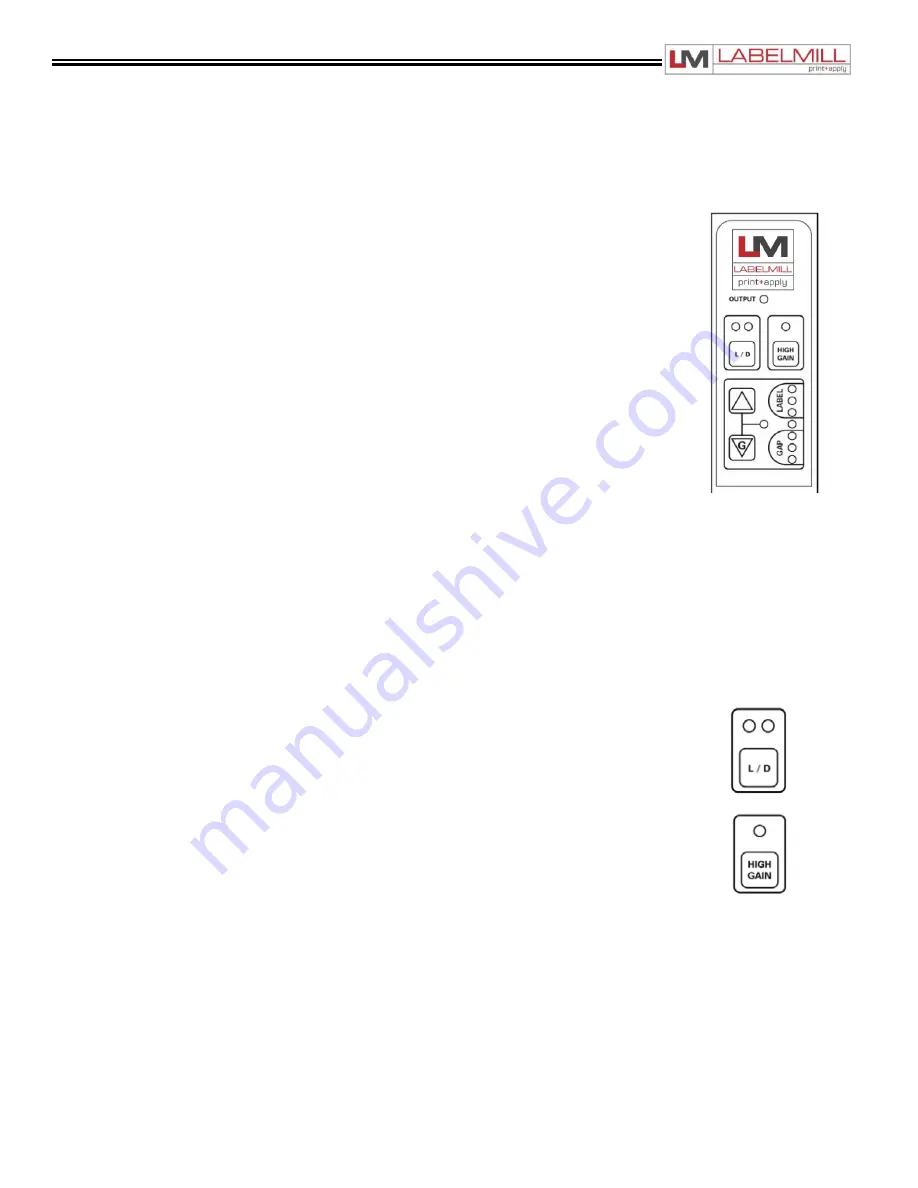

OPTIONAL ELECTRONIC CLEAR LABEL DETECTOR (ECLD)

Description

The Z-Z-ELC300 Label Sensor uses capacitive technology to sense label edges for registration, counting, splice detection

or other applications. Capacitive technology provides the fastest and most accurate edge detection method available. The

Z-Z-ELC300 has an integral cable, and uses an M12 connector.

Setup

1. Web must remain in contact with the base/mounting plate during operation.

2. Label must pass under the [-SENSOR-] indicator.

3. Small labels should be centered under the [-SENSOR-] indicator.

4. When properly setup, the lights in the gray LABEL area will be on when a label is

present, and lights in the gray GAP area will be on when a gap is present.

5. All lights flashing rapidly indicates over-current condition, likely caused by wiring error.

AutoGap Setup

1. Start with High Gain off.

2. Remove a label from the web.

3. Place the area of the missing label in the sensor (liner only).

4. Press for at least 1 second (lights begin to move back and forth).

5. Release the button.

6. Setup complete.

7. Verify the light bar goes into the gray GAP area during gaps between labels and into the gray LABEL area

during labels. If necessary, use arrow keys to adjust manually. If the light bar is not moving at least three or

four lights, turn on High Gain.

Manual Adjustment

When running, the light bar should extend from the gray LABEL area to the gray GAP area. The up and down arrows can

be used to fine tune the adjustment if necessary. If the adjustments reach the end of their range, the last light in the GAP

or LABEL area will flash three times when the button is pressed. The light bar may move toward LABEL while the Up

arrow is pressed. This is because the sensor body is deflecting and making the slot smaller. It will return when the button

is released and will not affect setup.

Sensor Configuration

Li

ght/Dark Switching In “Light” switching mode, the sensor outputs are active/on during the gap. In

“Dark”

switching mode, the sensor outputs are active/on during the label. Switch modes by pressing the

button.

Do not change while running.

High Gain Mode

Only use High Gain mode when necessary. Very small or very thin labels may not consistently move

the light

bar between the LABEL and GAP areas. In this case, use the High Gain mode by pressing the

button.

Do not change while running. AutoGap must be performed after activating High Gain.

Metal/Foil Label Setup

AutoGap Setup on a missing label area may not work reliably for rectangular metallic labels (foil or metalized Mylar). In

this case, place an actual gap in the sensor (use alignment groove on the sensor). Then hold the Gap button down for

AutoGap as above. Move labels slowly through the sensor. Use manual adjustments if necessary to ensure the light bar

is in the LABEL area during labels and GAP area during gaps.