LM1012TTS Table-Top Label Applicator System

USER'S MANUAL

Made in the U.S.A.

© 2022 LABELMILL

01/01/2022 Model LM1012TTS

Page 47

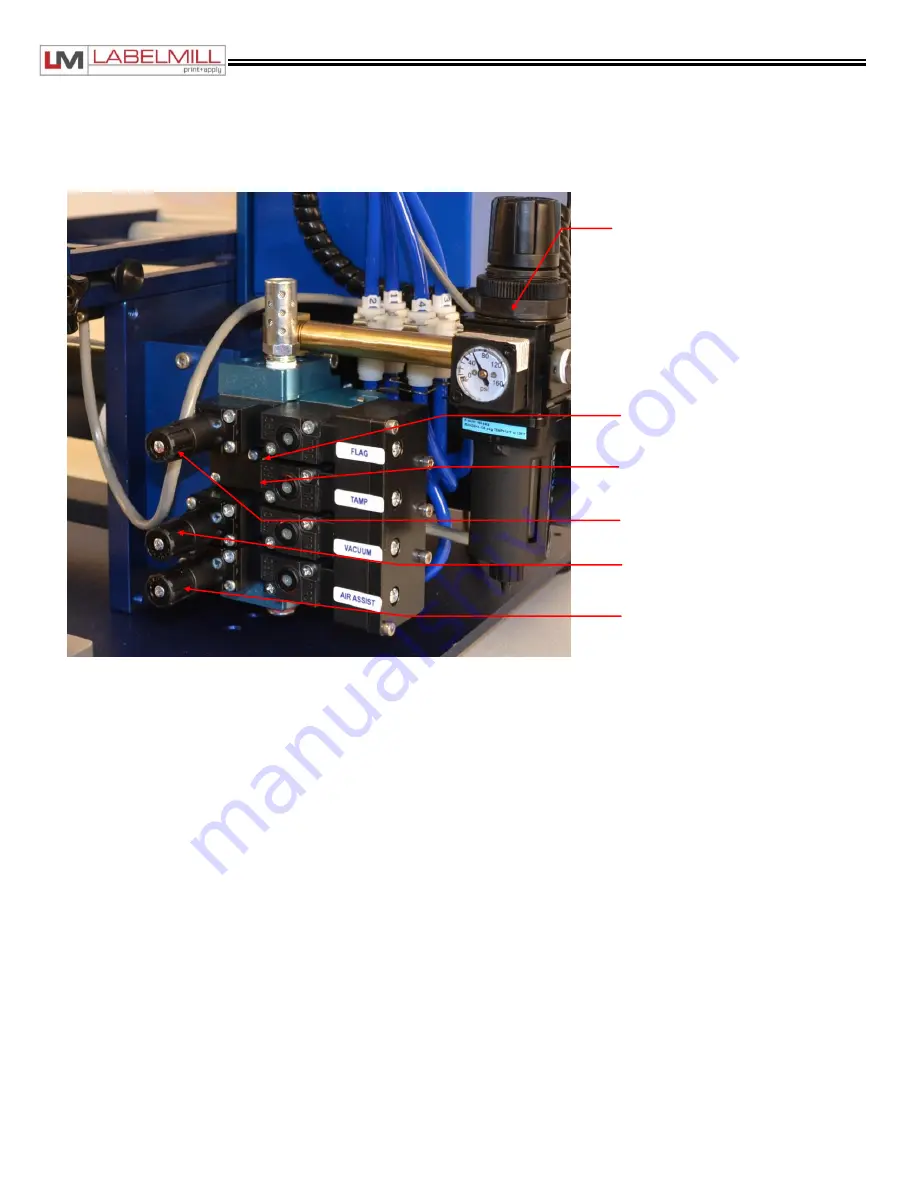

Valve Pack

The LM1012TTS valve pack is used to control the air pressure & flow on the tabletop system.

Regulator Adjustment:

Clockwise

- Increase pressure

Counterclockwise

- Decrease pressure

MAIN AIR REGULATOR

Controls maximum air pressure available to entire applicator. Should be set between 40 & 80 PSI.

FLAG REGULATOR

The flag regulator is used to adjust the pressure that the flag jaws apply to the label as it is applied. For complete jaw

adjustment, refer to flag applicator module installation.

VACUUM REGULATOR

(only used on the flag and tamp applicator system)

The vacuum regulator is used to control the vacuum that is used to hold the label to the flag jaws or the tamp pad.

AIR ASSIST REGULATOR

The air assist regulator is used to change the pressure that is applied to the blow tube. The blow tube is below the front

edge of the peeler plate and is used to help “push” the label onto the bottom of the tamp pad or the flag jaws.

FLOW CONTROLS

(tamp, round, and flag applications)

Control A: This is used to adjust the speed that the tamp cylinder moves in the upward direction.

Control B: This is used to adjust the speed that the tamp cylinder moves in the downward direction.

Flag regulator

Vacuum regulator

Air assist regulator

Flow controls (A)

(Brass Screw)

Flow controls (B)

(Brass Screw)

Main Air Regulator