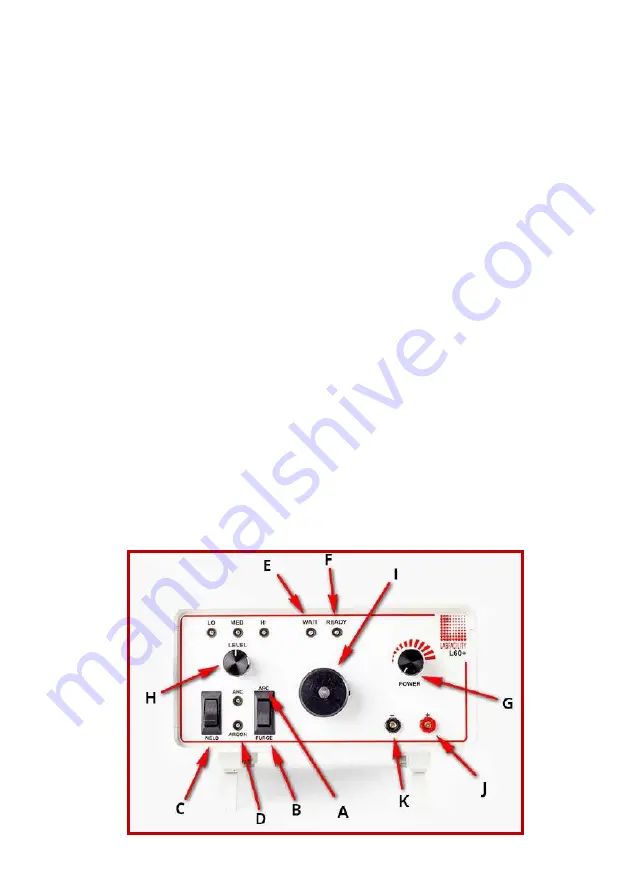

Front Panel Controls

A. Arc

Argon gas and weld current controlled by

the “Weld” switch. LED indication.

B. Purge

Allows the gas line and electrode shield to

be purged of air prior to a new welding period

C. Weld Switch

Initiates a welding operation (in “arc” mode

also opens the Argon valve).

D. Argon LED

Indicates when the Argon control valve is

open and gas is flowing.

E. Wait LED

Glows when weld charge is building.

F. Ready LED

“Ready to Weld” indication.

G. Power

Rotary control of the capacitor charge voltage.

H. Level selector

Selects the total capacitance available giving

the following values with LED indication.

“LO” = 0 to 6 Joules

“MED” = 0 to 28 Joules

“HI” = 0 to 64 Joules

I. Electrode Holder

Holds the replaceable carbon electrode which

is accessible by removing the outer Argon

Shield.

J. Red socket

Output socket for using the pliers supplied.

K. Black socket

Output socket, this provides an additional

earth point if required.

-

4

-