OilSET-1000 Oil Separator Alarm Device

D15492AE-2

Installation and Operating Instructions

Copyright © 2019 Labkotec Oy

7/13

We reserve the right for changes without notice

Oil Alarm and Fault LED indicators are immediately on.

Buzzer is immediately on.

Relays de-energize after 2 sec of continuous pressing.

When the Test push button is released:

LED indicators and buzzer go immediately off.

Relays energize immediately.

Alarm on

When pressing the Test push button:

Fault LED indicator is immediately on.

Oil Alarm LED indicator remains on.

Buzzer remains on. If it has been reset earlier, it will return to be on.

If relay 1 was already reset, it will de-energize again after 2 sec. of

continuous pressing.

Test will not affect relay 2, because it is already in alarm status.

When the Test push button is released:

The device returns without delay to the preceding status.

Fault alarm on

When pressing the Test push button:

The device does not react to the test at all.

3.2

Factory settings

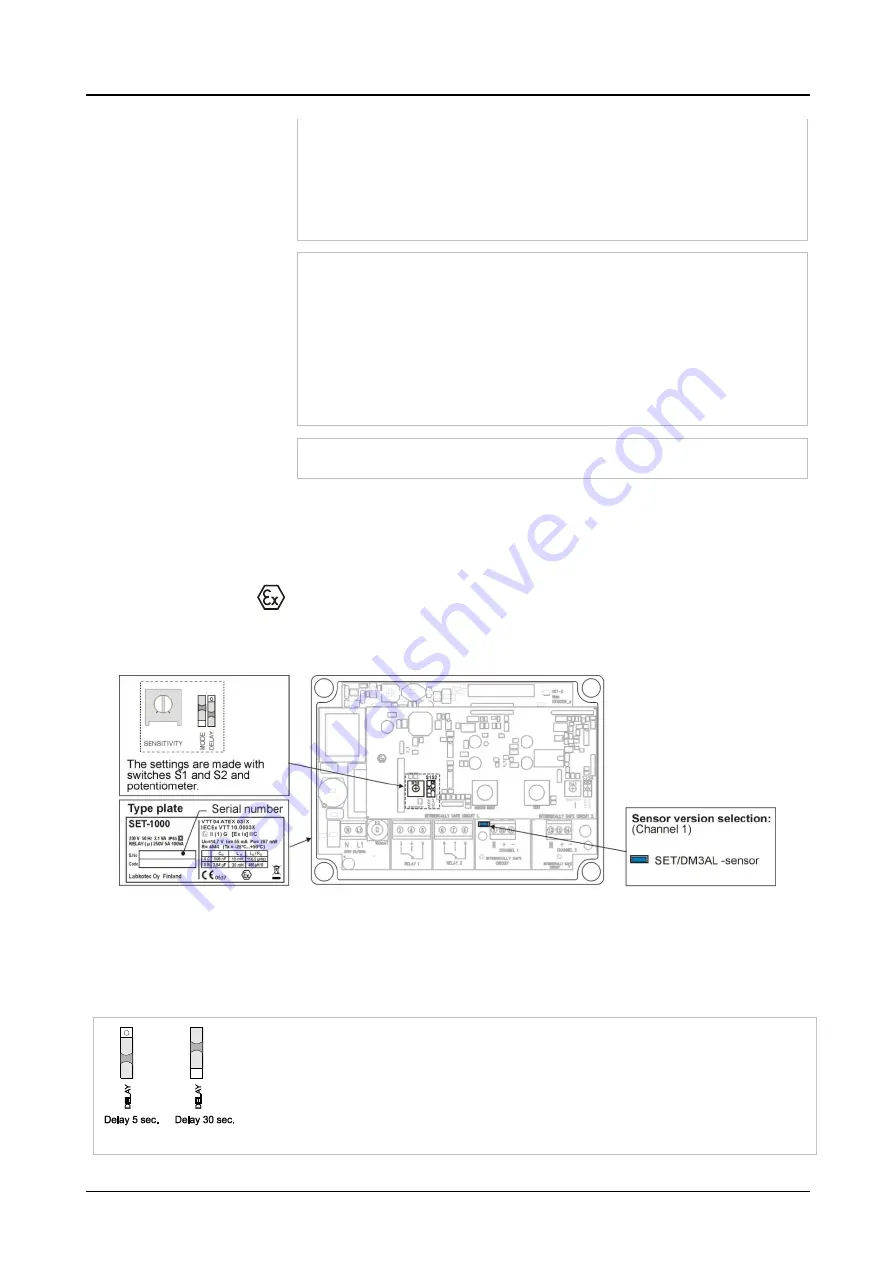

If the operation of OilSET-1000 is not as described in the previous

chapter, check that the device settings are as in figure 7. Change the

settings according to the following instructions if needed.

The following tasks must only be executed by a person with proper

education and knowledge of Ex-i devices.

We recommend, that when altering the settings the mains voltage is off

or the device is initialized before the installation is executed.

Figure 7. Factory settings

The settings are made with switches (MODE and DELAY) and

potentiometer (SENSITIVITY) located in the upper printed circuit board,

and the jumper located in the lower board (figure 7). In figure 7, the

switches are as set in the factory.

Switch S2 is used to set the

operational delay of the control unit

. When the switch is in low

position, relays operate and buzzer is on after 5 seconds after the level has reached the trigger

level, and if the level still remains on the same side of the trigger level.

When the switch is in high position, the delay is 30 seconds.

Delays are operational in both directions (energizing, de-energizing). Alarm LED follows the

sensor current value and trigger level without delay. Fault alarm takes place after a fixed delay

of 5 sec.

Summary of Contents for OilSET-1000

Page 11: ...DECLARATION OF CONFORMITY...

Page 12: ...DECLARATION OF CONFORMITY...

Page 13: ...DECLARATION OF CONFORMITY...