OilSET-1000 Oil Separator Alarm Device

D15492AE-2

Installation and Operating Instructions

Copyright © 2019 Labkotec Oy

8/13

We reserve the right for changes without notice

4

TROUBLE-SHOOTING

Problem:

MAINS LED indicator is off

Possible reason:

Supply voltage is too low or the fuse is blown. Transformer or MAINS LED

indicator is faulty.

To do:

1. Check if the two pole mains switch is off.

2. Check the fuse.

3. Measure the voltage between poles N and L1. It should be 230 VAC + 10 %.

Problem:

No alarm when sensor in oil or air, or the alarm will not go off

Possible reason:

The SENSITIVITY setting is wrong in the control unit (see figure 7), or sensor is

dirty.

To do:

1. Clean-up the sensor and lift it up in the air or immerse it into oil.

2. Turn the SENSITIVITY potentiometer slowly anticlockwise until the sensor gives

an alarm.

3. Immerse the sensor into water and wait until the alarm goes off. If the alarm

does not go off, turn the potentiometer slowly clockwise until the alarm goes off.

4. Lift the sensor up in the air or oil. The sensor should give an alarm again.

Problem:

FAULT LED indicator is on

Possible reason:

Current in sensor circuit too low (cable break) or too high (cable in short circuit).

The sensor might also be broken.

To do:

1. Make sure, that the sensor cable has been connected correctly to the OilSET-

1000 control unit. See sensor specific instructions.

2. Measure the voltage separately between the poles 10 and 11. The voltages

should be between 10

,3….11,8 V.

3. If the voltage is correct, measure the sensor current. Do as follows:

3.1 Disconnect sensor

’s [+] wire from sensor connector (pole 10).

3.2 Measure short circuit current between [+] and [-] poles.

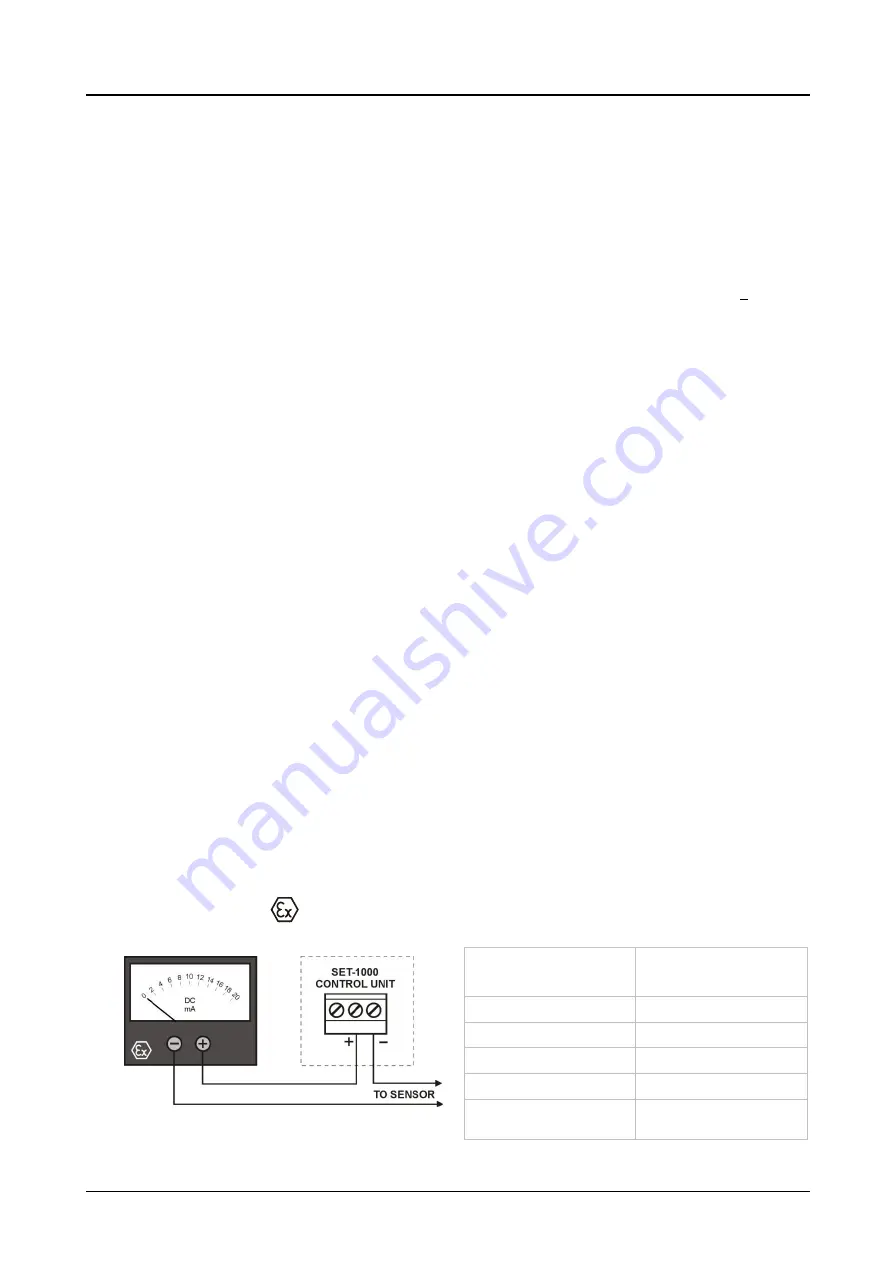

3.3 Connect mA-meter as in figure 8.

Make a comparison to the values in Table 1.

3.4 Connect the wire back to the connector.

If the problem can not be solved with the above instructions, please contact

Labkotec

Oy’s local distributor or Labkotec Oy’s service.

Attention! If the sensor is located in an explosive atmosphere, the multimeter must

be Exi-approved!

SET/DM3AL, channel 1

Poles 10 [+] ja 11 [-]

Shortcircuit

20 mA

– 24 mA

Sensor in the air

9

– 11 mA

Sensor in oil

(

r

2)

9

– 11 mA

Sensor in the water

3

– 4 mA

Factory setting for

alarm point

approx. 6.5 mA

Figure 8. Sensor current measurement

Table 1. Sensor currents

Summary of Contents for OilSET-1000

Page 11: ...DECLARATION OF CONFORMITY...

Page 12: ...DECLARATION OF CONFORMITY...

Page 13: ...DECLARATION OF CONFORMITY...