MHP Operating & Maintenance Manual

15

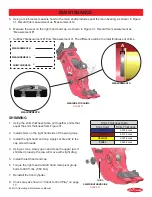

SWIFT-LOCK TEETH MAINTENANCE

When the jaw teeth are worn or cracking, performance is decreased and the teeth need to be replaced.

Removing the Upper Teeth

1.

Locate flat, hard ground and place the attachment

on the ground.

2.

Remove the washers, on each sides of each

tooth, using a grinder.

Note: The washers are welded into place.

3. Use a soft metal drift and a mallet to drive out the

tooth pin.

4. Remove the tooth from the receptacle.

Note: The retainer ring may fall out when removing the

teeth. Do not lose the retainer ring.

5. Insert the retainer ring in its place and insert a

new Swift-Lock tooth.

6. Insert the tooth pin and weld the washers in place.

Note: Insert the tooth pin so that the pin groove will

line up and seat in the retainer ring.

Removing the Lower Tooth Platen

1. Remove (6) M30 cap screws from the bottom of

the lower jaw. Do not reuse the cap screws.

2.

Remove the Lower Tooth Platen.

Note: There are 3 dowel pins press fit into the Lower

Tooth Platen for positioning. Insert new dowels into the

new Lower Tooth Platen.

3. Install a new Lower Tooth Platen. Apply Loctite

262 to the installation bolts and torque to 1350 ft.

lbs. (1850 Nm).

• Wear personal protection equipment at all

times. This includes eye protection, hard hat,

steel toe shoes, leather gloves and hearing

protection.

• Swift-Lock Teeth are very heavy. DO NOT

remove a tooth pin if the tooth is not

supported. The tooth may fall and cause injury.

MAINTENANCE

SWIFT-LOCK TEETH REMOVAL

Figure 16

SWIFT-LOCK

TEETH

TOOTH PIN

RETAINER

RING

WASHER

LOWER TOOTH

PLATEN

TOOTH

RECEPTACLE