18 MHP Operating & Maintenance Manual

MAINTENANCE

BLADE MAINTENANCE

• Wear leather work gloves at all times during

blade maintenance.

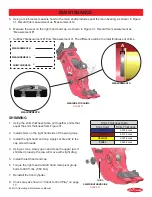

1.

Remove the blade as shown in Figure 21.

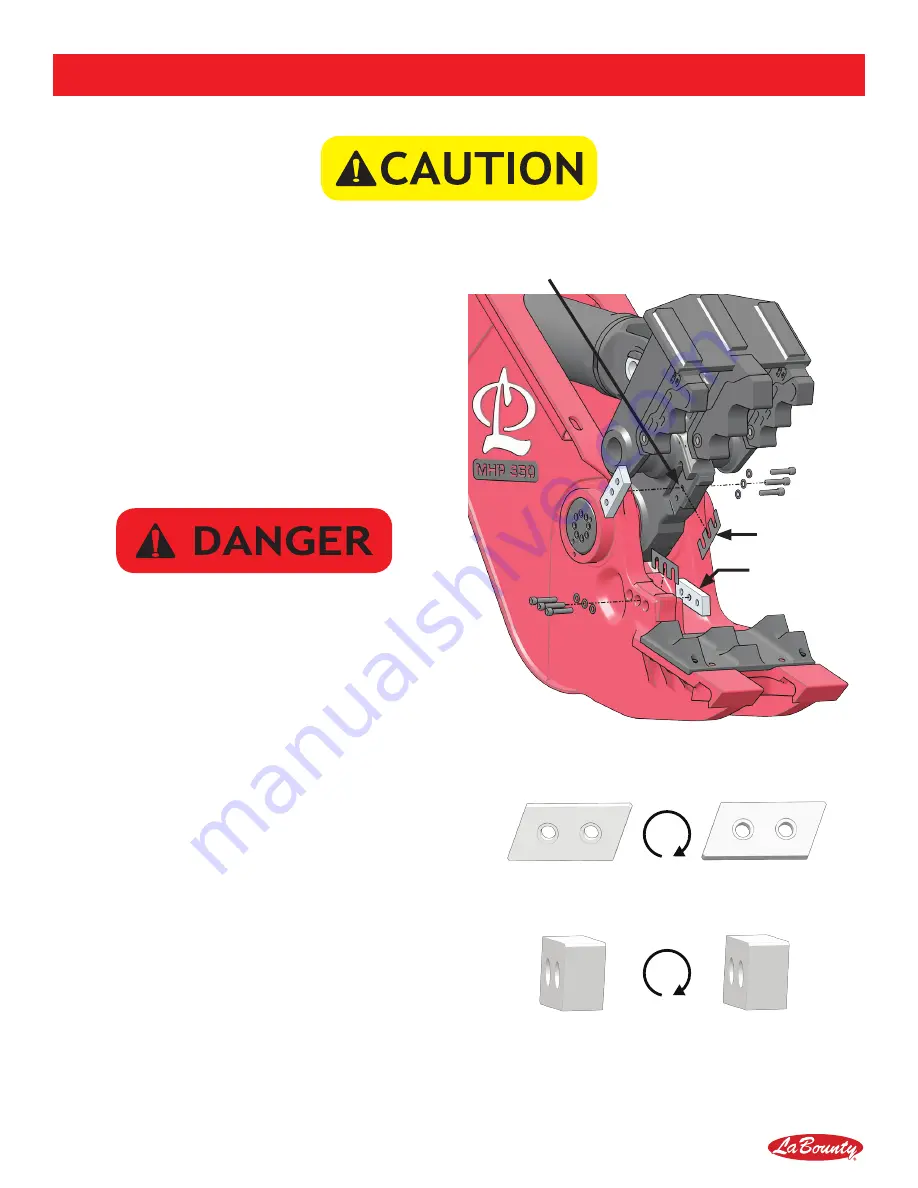

2. Grind all rough edges from each blade and clean

the blade seat.

3. Rotate the blade.

Note: Each blade has four edges, as shown in Figure

22 & Figure 23. Each time you rotate the blade, you use

a different edge. Replace blades when all edges are

rounded to .25” radius.

4.

Reinstall each blade using 500 ft. lbs. (680 Nm)

torque on each bolt.

• Stay at least 75 ft. (23 m) when moving.

5. Cycle the jaws closed. Measure the gap between

the upper and lower blade using a feeler gauge. If

the gap is larger than .030”, shim the blade.

Shimming the Blades

1. Measure the blade gap.

2.

Shim each blade so that the blade gap is

approximately .020”- .030”. Fit the shims between

the blade and the blade seat.

Note: Do not shim out a blade more than .125”. Doing so

may cause structural damage and will void the warranty.

A

B

180°

A

B

180°

A

B

C

D

A

B

D

C

BLADE PITCH ROTATION

Figure 22

BLADE ROLL ROTATION

Figure 23

BLADE & SHIM EXPLODED VIEW

Figure 21

SHIM

BLADE

BLADE SEAT