AUTOMIZER

VERSA HAND

TM

1-30

1.12.3

REPLACING SLIDING SHOES AND

WEAR PAD

Use a pry bar to move the packer up and

down and from side to side and if the

packer has a vertical movement greater

than 3/16” or a side movement greater

than 1/8”, verify both packer’s sliding shoes

as well as wear pads (Figure #1.30) under

the side rails.

Two different types of steel are used on

the packer guiding system: the AR-425

and the AR-500 type steel. The sliding

shoes are made of AR-425 type steel to

wear out before the floor guides, which are

made of AR-500. Refer to Body Parts

section for replacement part numbers.

To keep the packer in good working order

and to prevent breakdowns, replace the

sliding shoes and wear pads before

extensive wear or damage appears on the

hopper floor and walls.

SLIDING SHOE

FIGURE #1.30

SLIDING SHOE

REPLACEMENT PROCEDURE

1.

Note that it is not necessary to

remove the packer to perform this

procedure.

2.

Ensure that the parking brake is

applied and the vehicle is tagged

out for maintenance purposes

(refer to the section 1.5 “Lockout/

Tagout procedure”).

3.

Start the engine and engage the

hydraulic system.

4.

Then using the joystick, extend

the automated arm to give a better

access to the hopper area.

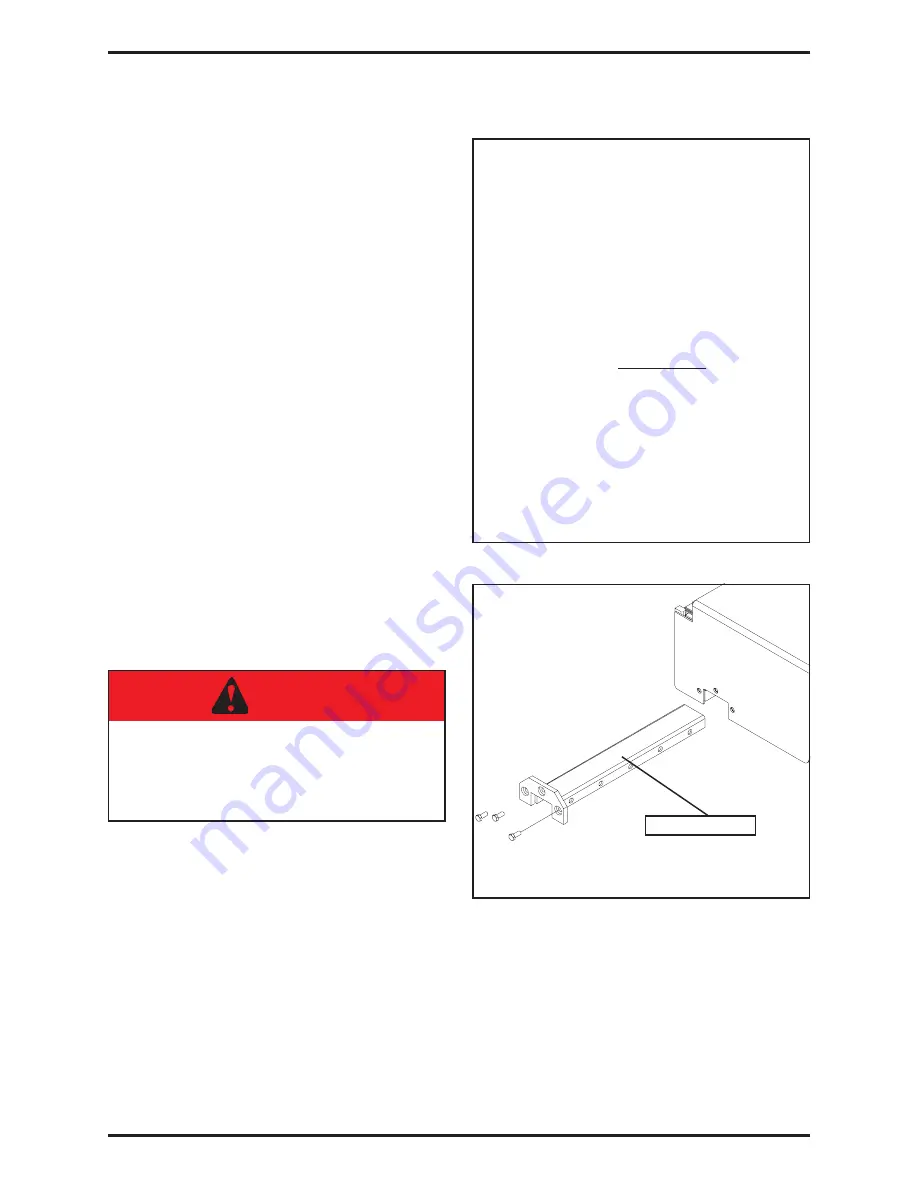

1.12.4

SLIDING SHOE REPLACEMENT

DANGER

SECURE THE AREA AROUND THE

PATH OF THE ARM WHEN

PERFORMING MAINTENANCE OR

REPAIR.

Summary of Contents for Automizer Versa Hand

Page 2: ...AUTOMIZER VERSA HANDTM 1 2...

Page 4: ...AUTOMIZER VERSA HANDTM 1 4...

Page 8: ...AUTOMIZER VERSA HANDTM 1 8...

Page 58: ...AUTOMIZER VERSA HANDTM 1 58 FIGURE 1 81 INPUT OUTPUT COVER ELECTRICAL COILS...

Page 69: ...1 69 GENERAL MAINTENANCE FIGURE 1 89A Strainer Seal...

Page 77: ...1 77 GENERAL MAINTENANCE A B C BEHIN D D F MAIN RELIEF B E...

Page 105: ...1 105 GENERAL MAINTENANCE NOTES...