AUTOMIZER

VERSA HAND

TM

1-54

1.14

HYDRAULIC SYSTEM MAINTENANCE

1.14.1

GENERAL MAINTENANCE

In order to keep the hydraulic system efficient and reliable, the following care must be

taken:

HYDRAULIC SYSTEM GENERAL INSPECTION PROCEDURE

1)

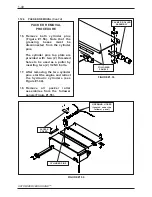

For new vehicle, change the return filter element after 50 hours of use, and twice a

year afterwards (See

section 1.14.7

“Filter replacement procedure”).

2)

Clean the strainer inside the tank after the first 50 hours of use, and once a year

afterwards. (See

section 1.14.8

“Strainer cleaning procedure”).

3)

Hydraulic oil must be replaced at least once a year or when contaminated.

(See

section 1.14.6

“Hydraulic oil replacement procedure”).

4)

When maintenance is carried out, protect all hoses, fittings and pipes or any other

holes from dirt that would eventually get into the oil. Use plugs to block hoses that

are not connected.

5)

Monthly inspect and adjust (If necessary) the oil pressure of the hydraulic system.

(See

section 1.15

“Hydraulic pressure adjustment).

6)

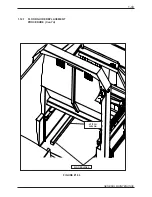

On a daily basis, inspect the hydraulic lines and connections for leaks, and correct

if necessary;

7)

Inspect the pump for leaks or unusual noise;

8)

The ball valve on the hydraulic tank must be completely open before engaging the

pump or starting the engine (See

section 1.9

“Prior to Start up”).

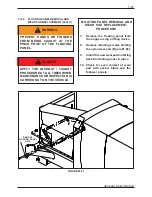

Labrie Equipment Ltd. requires that the

hydraulic fluid and return oil filter be changed

and the strainer cleaned before changing

the hydraulic pump.

Manufacturer’s warranty on hydraulic

pumps provided or sold by Labrie Equipment

Ltd. could be declared void if the hydraulic

fluid and return oil filter are not changed

and if the strainer is not cleaned prior to

replacing the hydraulic pump.

Therefore, it is mandatory to change the

return oil filter and clean the strainer after

the first 50 hours of use and then once a

year. The hydraulic fluid must be changed

annually. Hydraulic fluid contamination can

cause severe damage to the hydraulic

components.

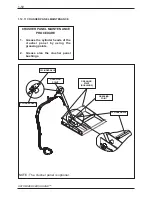

It is recommended to have the hydraulic

fluid tested and analyzed by a lab to prevent

hydraulic system or pump breakdown. This

will also optimize the hydraulic fluid change

frequency. Labrie trucks are now equipped

with an “oil sampler coupler”. See section

2.1.6 of the Lubrication manual.

Note that proofs of maintenance and/or

fluid samples could be requested when

filing warranty claims concerning the

hydraulic system or pump.

Summary of Contents for Automizer Versa Hand

Page 2: ...AUTOMIZER VERSA HANDTM 1 2...

Page 4: ...AUTOMIZER VERSA HANDTM 1 4...

Page 8: ...AUTOMIZER VERSA HANDTM 1 8...

Page 58: ...AUTOMIZER VERSA HANDTM 1 58 FIGURE 1 81 INPUT OUTPUT COVER ELECTRICAL COILS...

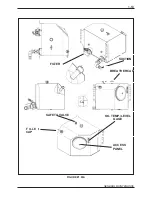

Page 69: ...1 69 GENERAL MAINTENANCE FIGURE 1 89A Strainer Seal...

Page 77: ...1 77 GENERAL MAINTENANCE A B C BEHIN D D F MAIN RELIEF B E...

Page 105: ...1 105 GENERAL MAINTENANCE NOTES...