91

Expert(t) 2000

TM

Maintenance Manual

Cycle Time for All

Hydraulic Functions

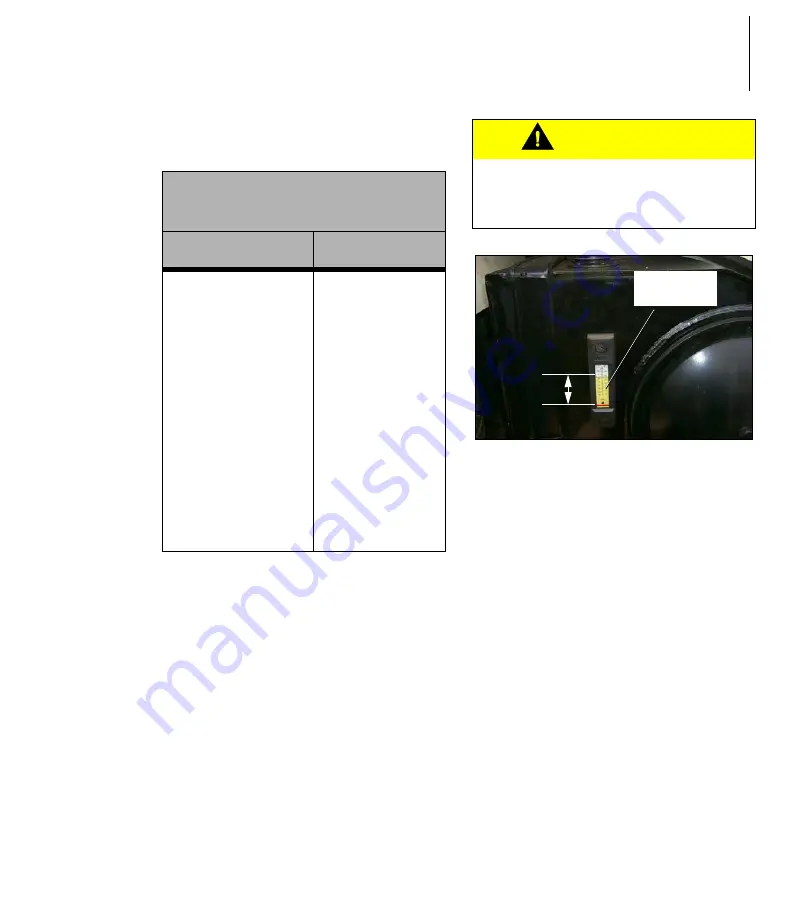

Hydraulic Tank

Inspection Procedure

Verify that the oil in the reservoir is

clean and always at the appropriate

level. The oil must be clean and not

colored.

Figure 143. Hydraulic Tank Gauge

1.

Make sure the parking brake is

applied and the vehicle is tagged

out for maintenance purposes

(refer to “Lockout/Tagout

Procedure” on page 8);

2.

Clean the strainer and replace

the filter element inside the tank

after the first 50 hours of service.

Refer to “Strainer Cleaning

Procedure” on page 96;

3.

Change the return filter element,

twice a year (after the first 50

hours). Refer to “Filter Element

Replacement Procedure” on

page 94;

Engine at 1200RPM (vane

pump)

V

ANE

PUMP

C

YCLE

T

IME

C

RUSHER

PANEL

4-5

SEC

.

T

AILGATE

40-50

SEC

.

P

ACKER

12-14

SEC

.

B

ODY

HOIST

55-65

SEC

.

CAUTION

M

AXIMUM

TEMPERATURE

FOR

HYDRAULIC

OIL

IS

180°F.

Oil Gauge

Temperature

¾ of Oil

Level

Gauge

Summary of Contents for expert 2000

Page 1: ......

Page 2: ......

Page 3: ...MAINTENANCE MANUAL 12 14 2006 Part 55379 ...

Page 4: ......

Page 10: ...viii Table of Contents ...

Page 96: ...86 CHAPTER 3 Maintenance Figure 141 Proximity switch front view ...

Page 118: ...108 CHAPTER 3 Maintenance Figure 170 Ball valve in closed position ...

Page 140: ...130 CHAPTER 4 Lubrication PACKER ...

Page 141: ...131 Expert t 2000TM Maintenance Manual BODY CHASSIS HINGES ...

Page 142: ...132 CHAPTER 4 Lubrication HOPPER SECTION STANDARD VERSION ...

Page 143: ...133 Expert t 2000TM Maintenance Manual CRUSHER PANEL ...

Page 144: ...134 CHAPTER 4 Lubrication FULL WIDTH TAILGATE ...

Page 154: ...144 CHAPTER 5 Troubleshooting ...

Page 156: ...146 Appendix CONNECTORS Commonly used Electrical Connectors Deutsch AMP ...

Page 168: ...158 Appendix ...

Page 170: ...160 Appendix ...

Page 171: ......

Page 172: ......