134

General Maintenance

26.

Retract the packer completely.

27.

Turn OFF the hydraulic pump and the engine.

28.

Lock out and tag out the vehicle (see

Locking Out and Tagging Out the Vehicle

29.

Align the packer with the hopper walls.

30.

Tack weld both floor guides to the floor in front of the packer.

31.

Weld both sliding shoes to the packer.

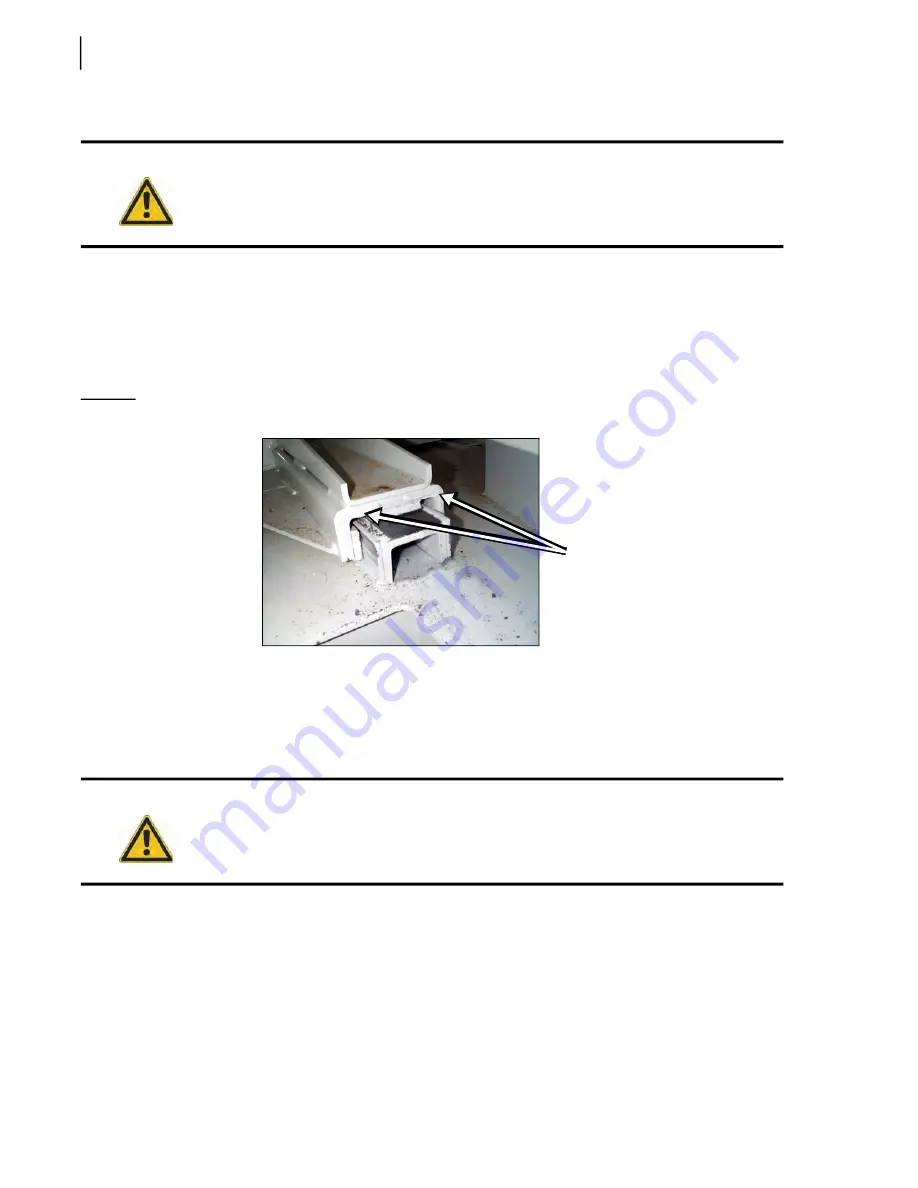

Figure 3

-

177 View from behind fully retracted packer

Finishing Up Replacing Sliding Shoes and Floor Guides

Apply the following procedure to finish up replacing the sliding shoes and floor guides:

1.

Run the packer a few times.

1 a.

If the packer is binding, apply some primer paint on the floor guide to find out where the

rubbing is occurring.

1 b.

Run the packer a few times again. The location where the paint has come off indicates the

surface that needs to be grinded.

2.

If the packer slides properly, weld the floor guides to the floor as illustrated in Figure 3

178.

3.

Fully extend the packer to finish welding behind it.

Danger!

Never enter the hopper while the packer is moving.

Danger!

Never enter the hopper while the packer is moving.

Weld

here

Summary of Contents for EXPERT

Page 1: ...EXPERT TM MAINTENANCE MANUAL...

Page 2: ......

Page 3: ...EXPERT MAINTENANCE MANUAL...

Page 10: ...viii Table of Contents...

Page 18: ...8 Introduction...

Page 244: ...234 General Maintenance...

Page 251: ...Lubrication 241 Figure 4 11 Glass compartment lubrication chart optional...

Page 252: ...242 Lubrication Figure 4 12 EXPERT lubrication chart...

Page 264: ...254 Lubrication...

Page 320: ...310 Hydraulic System...

Page 357: ...Troubleshooting 349...

Page 358: ...350 Troubleshooting...

Page 386: ...378 Multiplexing...