346

Troubleshooting

Step #3)

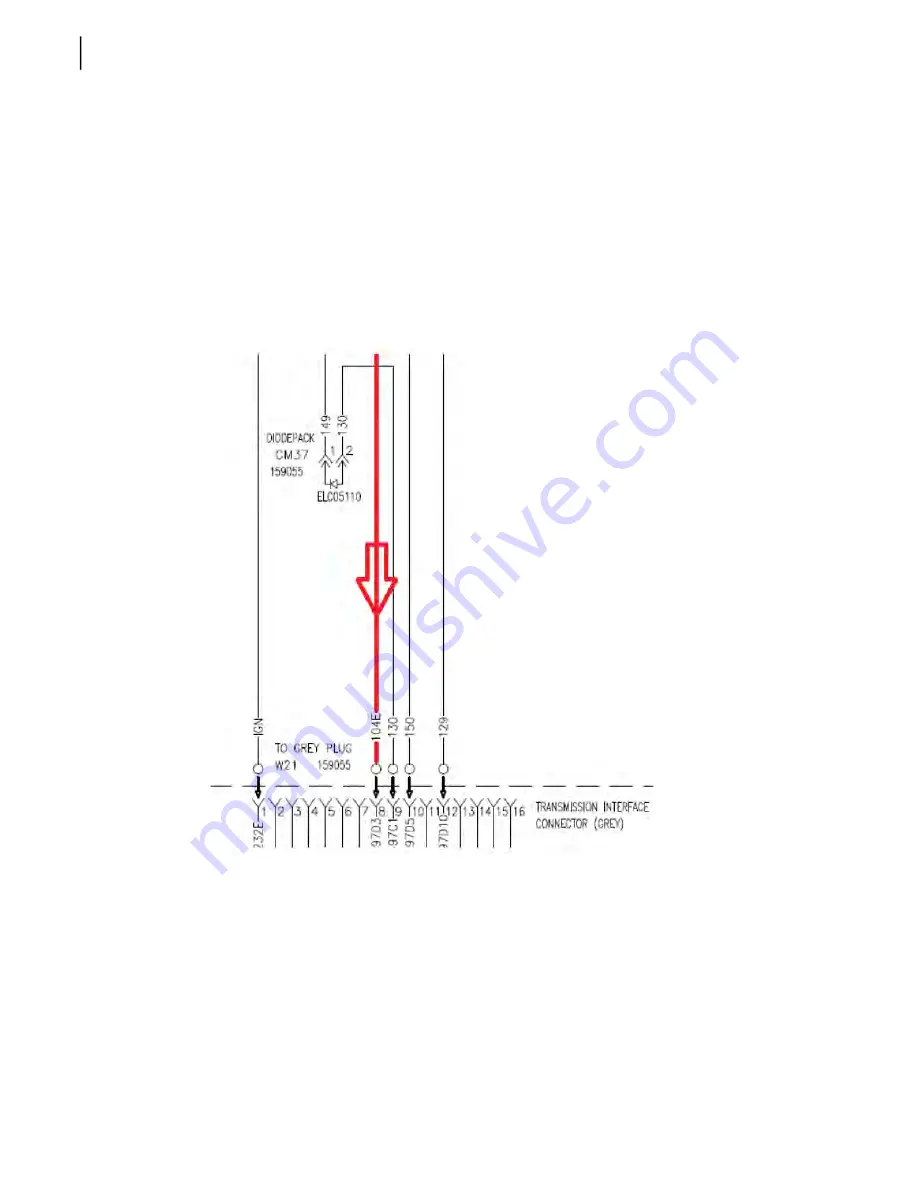

A) Locate output “OUT 12” and force it “ON”. With this output forced move to the appropriate

Labrie/chassis interface connector (see body serial number specific drawings for exact connector

number). Measure voltage on the pump trans request wire (104E).

If voltage is present

proceed to

step #4.

B)

If no voltage is present

, verify that voltage is leaving Node 10, wire 104o, pin 02, connector X20.

If voltage is not

leaving the module then the node 10 is defective/damaged; replace it.

If voltage is

leaving the module; there is one of two issues. Either a break in the wiring caused by an Emergency

stop switch/panic bar or an outside fault (such as an abraded/cut wire, corrosion/water in a

connector, etc.) is present. Repair the 104 wire before proceeding to step #4.

Step #4) Locate wire 130 on the same chassis interface connector and check for voltage.

If no voltage

is present, the transmissions parameters for pump engagement are not met (service transmission

and/or TCM).

If voltage

is present on wire 130 then locate the diode pack; this is located between

wires 130 and 149. Remove the diode pack and proceed to step #5.

Step #5) Perform a check of the diode pack using a digital multi-meter. With the multi-meter set to

the diode check function, place the red lead on pin 2 and the black lead on pin 1. There should be

continuity through the diode.

Summary of Contents for EXPERT

Page 1: ...EXPERT TM MAINTENANCE MANUAL...

Page 2: ......

Page 3: ...EXPERT MAINTENANCE MANUAL...

Page 10: ...viii Table of Contents...

Page 18: ...8 Introduction...

Page 244: ...234 General Maintenance...

Page 251: ...Lubrication 241 Figure 4 11 Glass compartment lubrication chart optional...

Page 252: ...242 Lubrication Figure 4 12 EXPERT lubrication chart...

Page 264: ...254 Lubrication...

Page 320: ...310 Hydraulic System...

Page 357: ...Troubleshooting 349...

Page 358: ...350 Troubleshooting...

Page 386: ...378 Multiplexing...