398

Lifting Arms

8 b.

Activate the in/out function by moving the joystick in one direction, then the other.

The further away the joystick is from its neutral position, the faster the arm moves.

When you move the joystick to the maximum in one direction, the signal voltage should be

either 3V or 9V. If it is 3V in one direction, it would be 9V in the other. The speed by which

the arm moves when the joystick is pushed to the fullest is the same, no matter which

direction the arm travels.

When the joystick gets closer to its neutral position, the arm slows down and when it

returns to its neutral position, the arm stops completely (see Figure 10

22).

The proportional signal is faulty when one of the following occurs: voltage is lower than 3V, higher

than 9V, no voltage at all or it is unstable.

If the signal voltage is lower than 3V the cause may be electrical: broken wire, faulty PWM adapter

25), corroded/damaged connector (see Figure 10

25), defective arm-controlling

module or mechanical: faulty coil, improperly adjusted hydraulic pressures, hydraulic bypass,

pinched lines, out-of-spec hydraulic requirements.

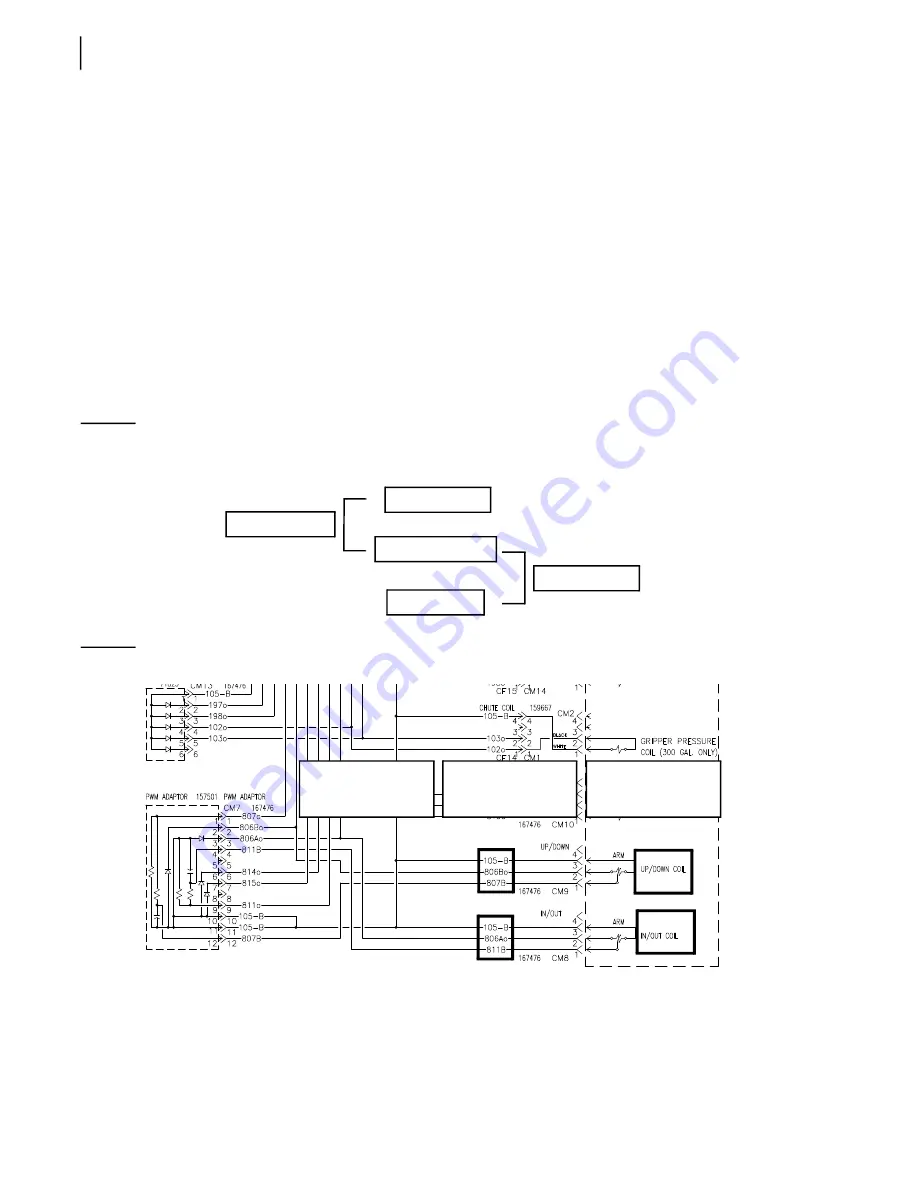

Figure 10

-

23 Testing voltage with a multimeter

Figure 10

-

24 Identifying wires on coil

12V Wire

Signal Wire

Ground Wire

First test

Second test

Ground Wire =

105B

12V Wire =

806Ao, 806Bo

Signal Wire =

807B, 811B

Summary of Contents for EXPERT

Page 1: ...EXPERT TM MAINTENANCE MANUAL...

Page 2: ......

Page 3: ...EXPERT MAINTENANCE MANUAL...

Page 10: ...viii Table of Contents...

Page 18: ...8 Introduction...

Page 244: ...234 General Maintenance...

Page 251: ...Lubrication 241 Figure 4 11 Glass compartment lubrication chart optional...

Page 252: ...242 Lubrication Figure 4 12 EXPERT lubrication chart...

Page 264: ...254 Lubrication...

Page 320: ...310 Hydraulic System...

Page 357: ...Troubleshooting 349...

Page 358: ...350 Troubleshooting...

Page 386: ...378 Multiplexing...