288

Hydraulic System

Hydraulic Pressures

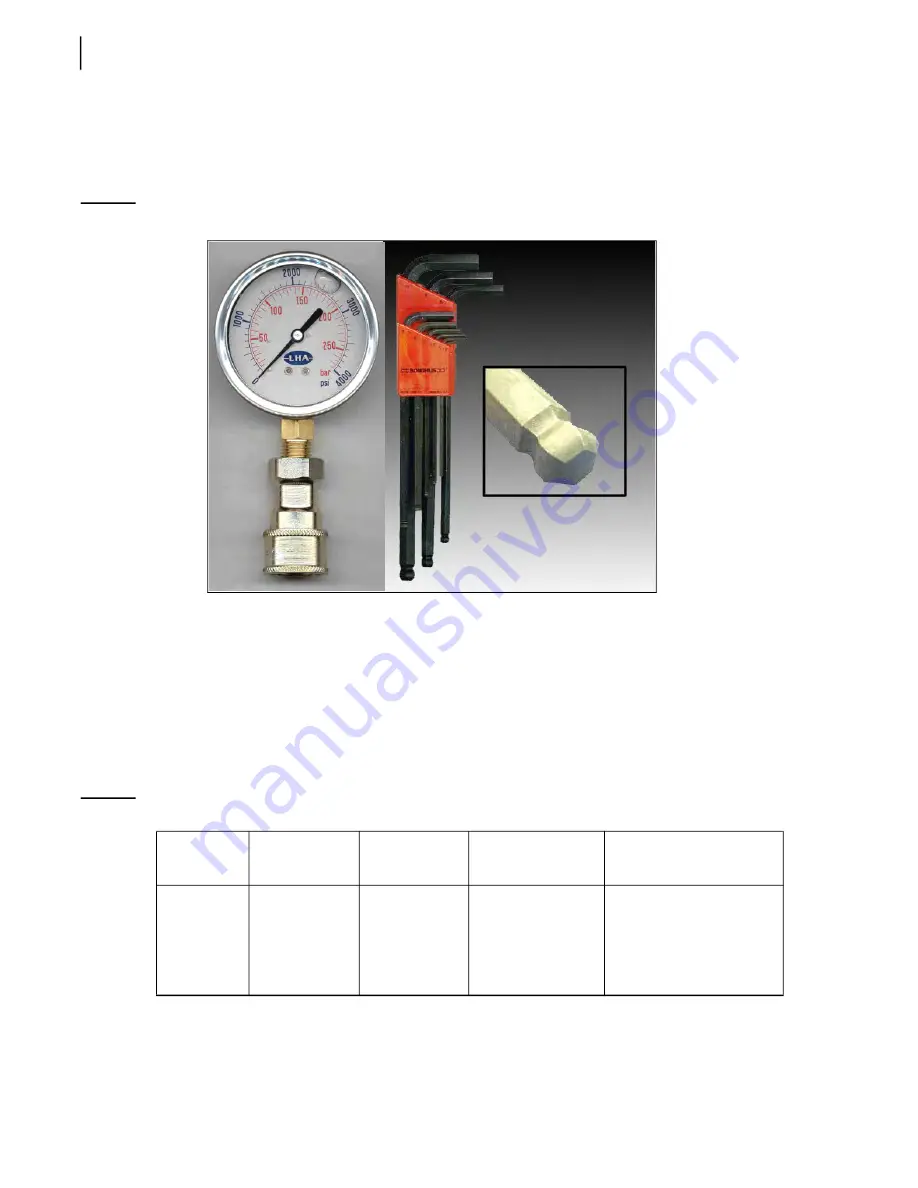

A 0–4000 PSI pressure gauge as well as a set of ball-end hex keys are required to adjust different

working pressures of the truck’s hydraulic system (see Figure 5

30).

Figure 5

-

30 Pressure gauge and ball-end hex key

Adjusting Vane Pump Relief Valves (if equipped)

The body and arm sections of the dual vane pump may have their own relief valve on the dump valve;

one located on the pump, the other on the chassis. Adjustment of vane pump relief valves must be

done before adjusting the relief valve of the directional control valve.

The following pressure chart gives the proper adjustment pressure for body functions. Use this chart

to adjust the relief valve for the body vane pump. For arm functions, see

Table 1

Pressure chart

Pump

Chassis

Cylinder bore

(packer)

Main relief

pressure (±50 PSI)

Dump valve pressure

(if equipped) (±50 PSI)

Vane pump 6×4

(tandem axle)

4×2

(single axle)

4 inches

4 inches

3,000 PSI at idle

2,000 PSI at idle

3,300 PSI at idle

2,200 PSI at idle

Summary of Contents for EXPERT

Page 1: ...EXPERT TM MAINTENANCE MANUAL...

Page 2: ......

Page 3: ...EXPERT MAINTENANCE MANUAL...

Page 10: ...viii Table of Contents...

Page 18: ...8 Introduction...

Page 244: ...234 General Maintenance...

Page 251: ...Lubrication 241 Figure 4 11 Glass compartment lubrication chart optional...

Page 252: ...242 Lubrication Figure 4 12 EXPERT lubrication chart...

Page 264: ...254 Lubrication...

Page 320: ...310 Hydraulic System...

Page 357: ...Troubleshooting 349...

Page 358: ...350 Troubleshooting...

Page 386: ...378 Multiplexing...