292

Hydraulic System

6.

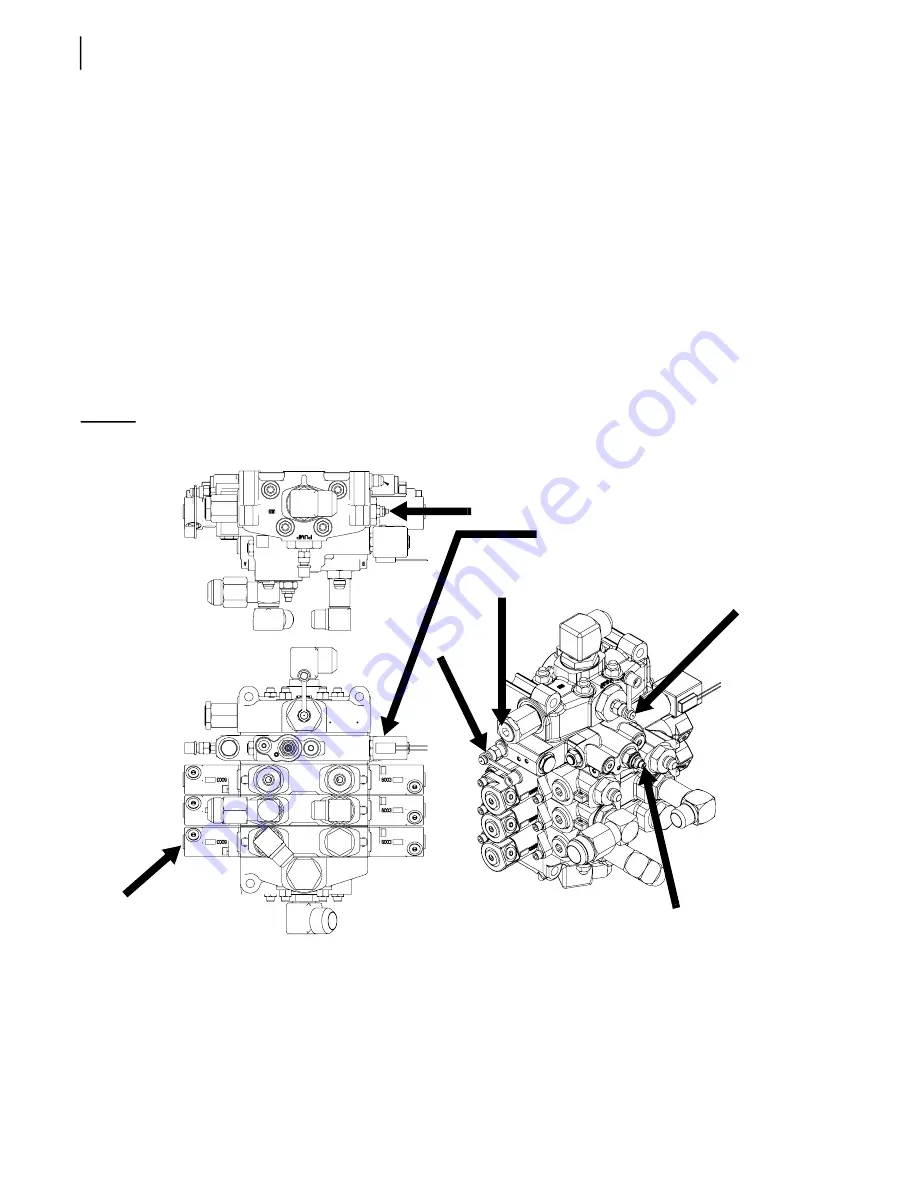

Disconnect the body-up coil (see C on Figure 5

35).

7.

With the engine at idle, adjust the pilot generating relief valve (see A on Figure 5

35) to 420 PSI

(±20 PSI) while the Body Up function is activated. The valve adjustment screw is located on the

right-hand side of the valve section when facing it.

8.

Reconnect the body-up coil.

9.

Remove the pressure gauge from the inlet cover and install it on the maximum pilot pressure port

(see D on Figure 5

35).

10.

Disconnect the packer extend proximity switch.

11.

Activate the packer extend until it reaches the end of stroke.

12.

Adjust the pressure reducing valve to 550 PSI (±20 PSI) using the adjustment screw located at

the front of the valve (see B on Figure 5

35).

13.

Test the valve.

The valve should shift sharply.

Figure 5

-

35 Valves and ports

Adjusting Proportional Valve Pressure

E

XPERT

™ vehicles use an extra valve stack to control the arm and the chute (if equipped). This valve is

of the proportional type, meaning that the amount of flow coming out of it depends on the position of

the spool.

A

C (behind)

F (main relief)

E

B

D

This section, known as the utility sec

-

tion, is fixed to an electro-hydraulic

valve only

Summary of Contents for EXPERT

Page 1: ...EXPERT TM MAINTENANCE MANUAL...

Page 2: ......

Page 3: ...EXPERT MAINTENANCE MANUAL...

Page 10: ...viii Table of Contents...

Page 18: ...8 Introduction...

Page 244: ...234 General Maintenance...

Page 251: ...Lubrication 241 Figure 4 11 Glass compartment lubrication chart optional...

Page 252: ...242 Lubrication Figure 4 12 EXPERT lubrication chart...

Page 264: ...254 Lubrication...

Page 320: ...310 Hydraulic System...

Page 357: ...Troubleshooting 349...

Page 358: ...350 Troubleshooting...

Page 386: ...378 Multiplexing...