Café Moderne Range Hoods

Installation, Operating & Maintenance Instructions

W1512 FMOD Moderne Range Hood O&M Dec 16.docx

Page 3

Fornair

Method

Mark a horizontal line on the wall where the bottom edge of

the hood needs to be - if you have already fitted a splashback

then the top edge of this will serve.

Mark a vertical centre line, up to the desired chimney height,

to help you to accurately position the hood and chimney

bracket later.

Remove the grease filters to gain access the internal fixing

holes.

Mark the positions of the hood fixing hole centres and prepare

the wall to accept your chosen fixings, see Figure 2 “Layout of

Hood Rear”.

Tip.

The easiest way to mark fixing hole positions on the wall

is to offer up the hood in the desired position and then mark

the wall through the fixing holes in the hood rear (working

through the filter openings).

This is a 2-person job.

Mark and prepare hole(s) suitable to accommodate 150mm

diameter ducting. A 175mm diameter hole is recommended to

provide some alignment tolerance and allow clearance for any

clips used to secure the duct or cables passing through to

remote motors. If using the rear exhaust spigot position then

accuracy is critical, see Figure 2.

Secure the hood, using fixings suitable for the wall

construction, in the previously marked positions

Tip

. To use the rear exhaust spigot position you may have to

connect the ducting prior to fixing the hood to the wall - rigid

ducting is strongly recommended.

Unscrew the chimney bracket from the inner telescopic

chimney section and mark the positions of the chimney fixing

bracket holes on your wall.

Please note:

The bracket finishes flush with the finished top

of the chimney and the central hole can be used to view your

centre line.

Tip.

The easiest way to mark fixing hole positions on the wall

is to offer the bracket up into the desired position and then

mark the wall through the fixing holes in the bracket rear.

Secure the chimney bracket, using fixings suitable for the wall

construction, in the previously marked positions.

Connect the ducting and electrical supply cord as described in

section 4.6 and 4.7.

Slide the inner chimney up and over the bracket and secure it

in position using the screws previously removed.

4.6. Electrical Supply

The extractor is a stationary appliance designed to be

connected by fixed wiring to the electrical supply. A competent

Part P registered electrical technician must perform the

electrical installation.

The hood must be fed from a 230Vac single phase electrical

supply using a switched spur fitted with a 3A fuse. The spur

should be located adjacent to the hood/cooker so that the

supply can be disconnected from the hood using the switch.

The means of disconnection from the supply must have a

minimum contact separation of 3mm in all poles. Alternatively,

a means of disconnection in the fixed wiring according to the

relevant wiring rules must be fitted.

The appliance is supplied with an electrical supply flex for

connection to the electrical supply. The mains supply is

connected to the free end of this flex as follows:

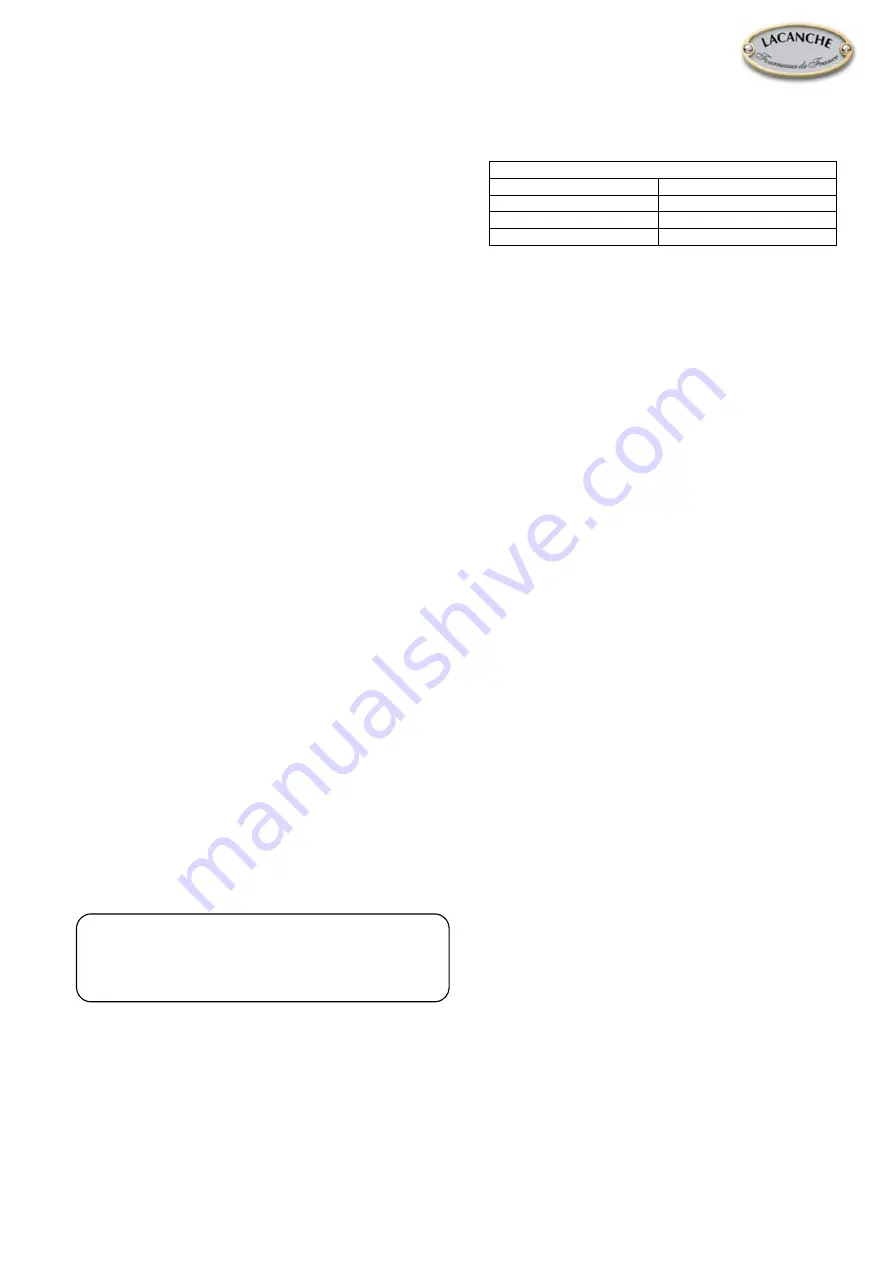

INCOMING SUPPLY CORD CONNECTIONS

Core

Core Colour

Live

Brown

Neutral

Blue

Protective Earth

Green/Yellow

4.7. Connecting the Ducting

Whether you start running ducting at the hood end or at the

termination point (where it exits the building) will depend upon

your site conditions. There is no right or wrong order,

providing that ducting is installed so that it is as smooth as

possible and can be disconnected should the need arise for

maintenance.

Terminate the ducting where it exits the building. If using a

wall mounted weather louvre, secure the ducting to the louvre

spigot and attach the louvre to the wall. Ensure that the air fins

are directed downwards. If you are fitting an alternative

termination, ensure that the ducting is secure.

If using expanding foam, make sure that any flexible ducting is

supported internally to prevent it crushing where foamed.

Pull flexible ducting back along its route such that it is as

smooth as possible.

Connect ducting to extractor exhaust spigot using plastic tie

straps or a suitable alternative (e.g. jubilee clip) - do not use

duct tape as the sole means of connection. For rear exit

exhaust positions the duct should be attached prior to fixing

the extractor to the wall.

When the extractor is in position, check that the duct has not

been flattened or kinked along its route.

Note: Internal motor models have non-return flaps as part of

the spigot assembly to reduce air blowing back into the unit

from outside.

Take care not to obstruct the backdraught flaps when

connecting ducting, making sure that the ducting is not

preventing the flaps from opening properly. This is most

commonly a problem that can be encountered when flexible

ducting is used and we recommend semi-rigid ducting is used

instead. Overtightening of jubilee clips close to the base of the

spigot can also prevent the flaps from opening properly. If you

have installed non-return flaps elsewhere and draughts are

unlikely to cause a problem, then these flaps are easily

removed.

ELECTRICAL HAZARD

DISCONNECT ELECTRICAL SUPPLY

BEFORE PROCEEDING FURTHER