Café Moderne Range Hoods

Installation, Operating & Maintenance Instructions

W1512 FMOD Moderne Range Hood O&M Dec 16.docx

Page 4

Fornair

5. OPERATING INSTRUCTIONS

Switch on the power at the fused spur.

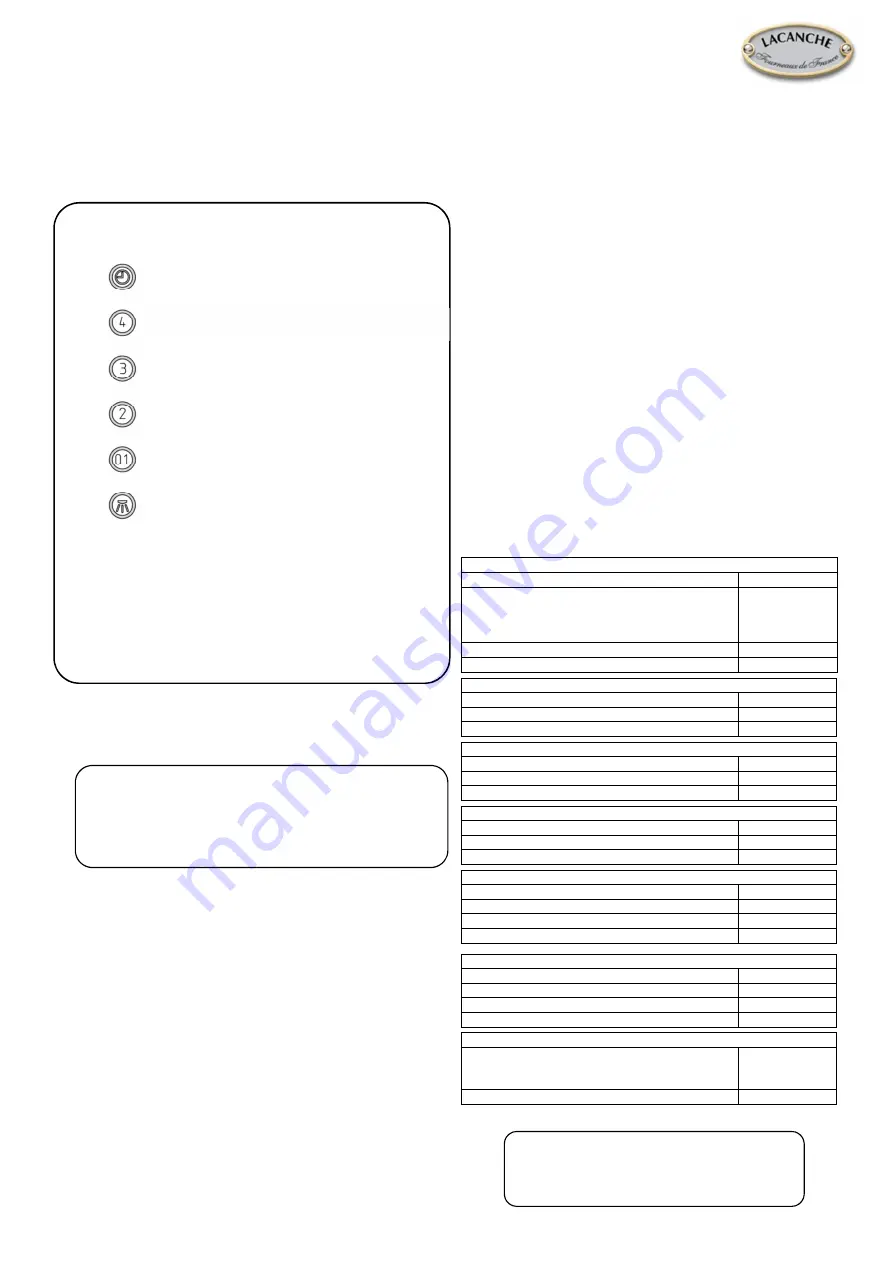

Your extractor has 6 pushbuttons which illuminate when

pressed.

6. MAINTENANCE

Regular maintenance is essential to ensure good performance

and long-life.

To maintain the immaculate appearance of the extractor, and

to minimise fire risk, ensure that grease deposits on the

extractor surfaces are kept to a minimum by regular cleaning.

To clean the stainless steel surfaces of the extractor, use a

soft cloth and a suitable cleaning agent, such as a specially

produced stainless steel cleaner or washing up detergent and

warm water.

Painted surfaces should be cleaned using a soft cloth,

detergent and warm water.

Glass surfaces should be cleaned with a suitable glass

cleaning agent.

•

Do not use abrasive cleaning materials or products.

•

Do not use bleach based cleaning materials or

products.

Clean the grease filters in a dishwasher or by hand-washing in

hot water and detergent every 2 months - sooner if the

extractor is used extensively and filters become grease laden.

•

Whilst you can expect years of service from mesh grease

filters, they are considered a consumable item and may

deteriorate over time and need replacement, particularly

when cleaned in a dishwasher. For dishwasher users

adhering to a 2-monthly cleaning interval we recommend

grease filter replacement every 5 years to maintain

optimum performance, even if they show no visible signs

of deterioration. For all users, filters should be replaced

whenever they exhibit signs of physical wear.

6.1. Removing the Grease Filters

The clip in grease filters have an integrated sprung latch

mechanism.

Release the latch by pulling the lever and remove the filter.

Filters are replaced by locating the fixed tabs opposite the

lever catch into corresponding slots in the extractor base and

then pushing the filter into position with the latch held open.

Once the filter is in position release the lever, allowing the

latch to engage.

6.2. Replacing Lamps

The lamps are long life LED units and are not designed for

end user replacement. In the unlikely event of failure please

call for assistance.

7.

SPECIFICATIONS

All Models

Supply Voltage:

230V~ 50Hz

Lighting: 12V 2.6W LED (Per Lamp):

12V, 2.6W

See general arrangement drawings for lamp

quantity installed in your model.

Per lamp

Extractor Duct Spigot Diameter:

150mm

Total power:

See rating plate

Internal Motor Specifications

Airflow, nominal in free air:

800 m

3

/hr

Power input:

275W

Duct Spigot diameter:

150mm

SEM1 EL Inline Duct Motor Specifications

Airflow, nominal in free air:

800 m3/hr

Power input:

275W

Duct Spigot diameter:

150mm

SEM2 EL Wall Mounted Motor Specifications

Airflow, nominal in free air:

1,000 m

3

/hr

Power input:

200W

Duct Spigot diameter:

150mm

SEM7 EL Wall Mounted Motor specifications

Airflow, nominal in free air: 200mm Dia Duct

1,700 m

3

/hr

Airflow, in free air via supplied 150mm reducer

1,500 m

3

/hr

Power input:

490W

Duct Spigot diameter:

200/150mm

SEM8 EL Inline Motor specifications

Airflow, nominal in free air: 200mm Dia Duct

1,300 m

3

/hr

Airflow, in free air via supplied 150mm reducer

1,100 m

3

/hr

Power input:

250W

Duct Spigot diameter:

200/150mm

Recommended Protective Fuse Sizes for Electrical Supply

Models installed with:

Internal Motor

Remote Motors

3A

CAUTION

To minimise the risk of fire, all instructions relating

to cleaning the grease filters and removing grease

deposits must be adhered to.

Pushbutton Functions

The extractor controller automatically switches off

the appliance if there has been no operator action

for 4 hours.

After 30 hours accumulated running GREASE

FILTER CLEANING will be signalled by all 6

indicators flashing. Reset by pressing Push-button

FAN OFF (delay).

Lights ON/OFF

Motor ON - SPEED 1

Motor OFF

Motor ON – TIMED INTENSIVE MODE

(Reverts automatically to speed 3 after 5 minutes)

Motor ON - SPEED 3

Maximum Speed for Normal Use

Motor ON - SPEED 2

Motor RUN ON TIMER

(OFF after 10 minutes to clear fumes)

For more detailed specification and energy

efficiency information please refer to the

product fiche for your product