Page 3 of 17 – US –

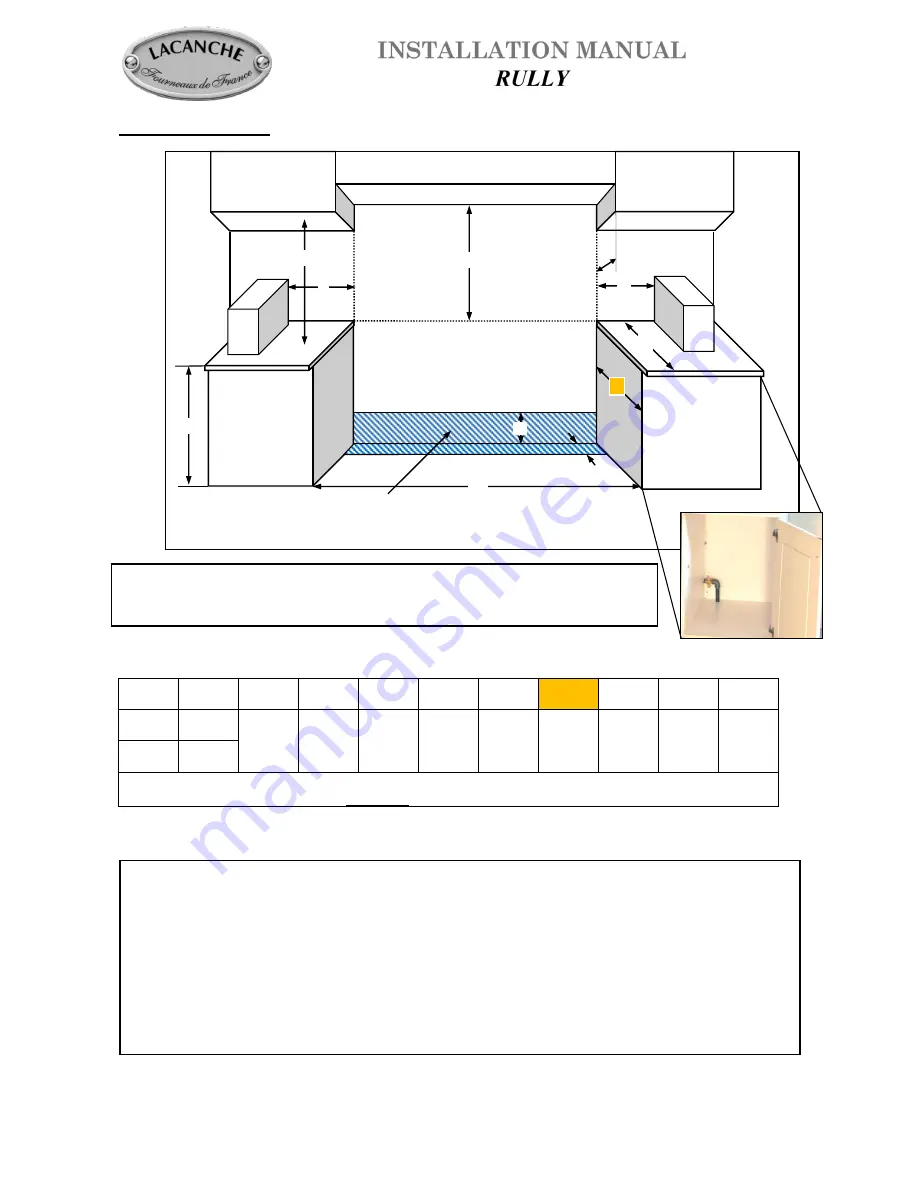

Cabinet preparation

:

ALL DEPTH MEASUREMENTS BELOW ARE WITH A 50mm (2”) RANGE SPACER INSTALLED:

Range

Height

A

(min*)

B

C

D

E

(max)

F

G

(max)

H

I

J

Default

900mm

35 3/8’’

457mm

18’’

914mm

36’’

330mm

13

’’

50mm

2’’

700mm

27 9/16’’

638mm

25 1/8’’

130mm

5 1/8’’

215mm

8 7/16’’

705mm

27 3/4’’

Optional

930mm

36 5/8’’

*All final range height dimensions are variable with the use of the adjustable range feet.

Maximum added height for the Roller Feet: 16mm -

5

/

8

’’

,

Extended Leveling Feet

: 30mm – 1

3

/

16

’’

The range is a free standing unit. If the unit is to be placed next to cabinets, the clearances shown in Figure 1

are required.

The range cooktop surface must be no lower than the adjacent base cabinet countertop surface.

Min clearances to combustibles:

0’’ (0 mm) from rear (with spacer installed).

0’’ (0 mm) from sides

below

countertop surface height.

2’’ (51 mm) from sides

above

countertop surface height.

Cabinets 13’’ (330 mm) deep may be installed above the range at least 30’’ above the plane of the

cooking surface.

Use range only with factory supplied legs.

A flexible metal gas line, and a flexible power cord should be used to attach the range to

the gas and electrical utility connections behind the range. When installed, the range wall

spacer allows a 130mm (5 1/8”) deep gap to run the utility lines behind the range chassis.

Fig. 1

J

D

E

E

G

Place electrical outlet in this shaded

area behind range

I

F

H

A

B

C

Place gas cut-off valve

at the back of this

cabinet or alternate

accessible location.

Route pipe through

cabinet wall into

shaded area