Page 4 of 17 – US –

Before connection

:

Check:

- Pipework is perfectly clean in order to prevent the injectors

becoming blocked and malfunctioning of the magnetic heads.

- The gas for which the appliance was set up: Rating plate and

markings.

- Cross-sectional area of gas supply pipework is compatible with the

appliance’s thermal output.

- Provide adequate air supply during use of the appliance.

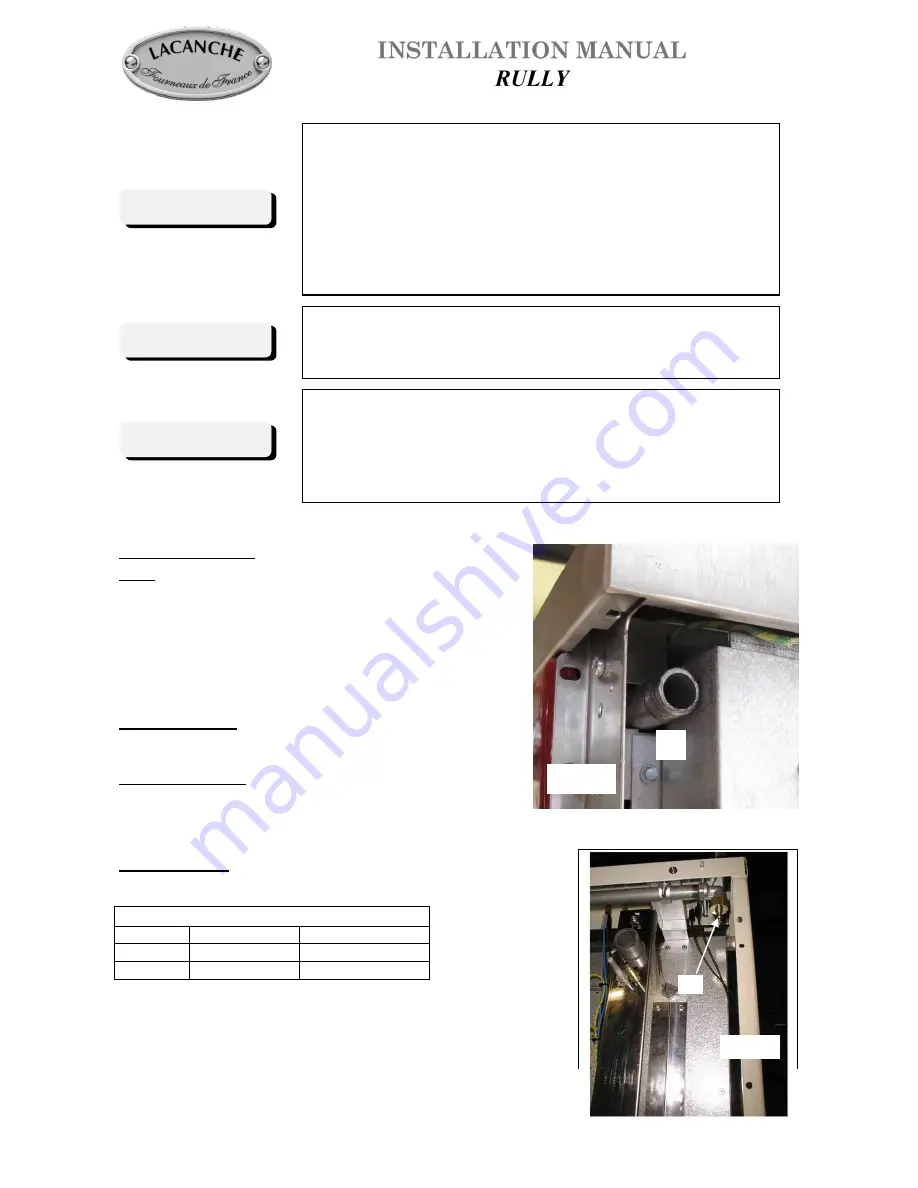

Gas connection

:

Female coupling Ø 15/21, 1/2” ID NPT on

A

(Figure 2).

After connection:

Check/test the manifold pressure on pressure connection Ø 15/21,

1/8” NPT on

B

(Figure 3, Table 2).

Change of gas:

The appliance is designed to operate with the gases in Table 2.

Table 2

Country

GAS

Pressure (Pn)

U.S.

Natural gas

6’’ WC

U.S.

L.P. propane

10’’ WC

If specified at the time of the order, the appliance will

be built to use the specified gas type. No further

work is required by the installer.

Fig. 3

B

IMPORTANT

Manual shut-off valve should be installed in an accessible

location in the gas piping external to the appliance for the

purpose of turning on or shutting off gas to the appliance.

A location at the back of an adjacent cabinet is

recommended.

THE

APPLIANCE

MUST

BE

INSTALLED

IN

ACCORDANCE WITH THE LOCAL CODES OR

National Fuel Gas Code, ANSI Z223.1 or latest edition.

IMPORTANT

Recommended to be installed under an exhaust hood.

In the commonwealth of Massachusetts, the appliance must

be installed by a licensed plumber or gas fitter.

Do not install this unit near combustible walls, partitions,

pieces of furniture or decorative material unless these are

covered by adequate material of the non-combustible type.

Making sure the resulting installation meets fire

regulations.

IMPORTANT

Fig. 2

A