31

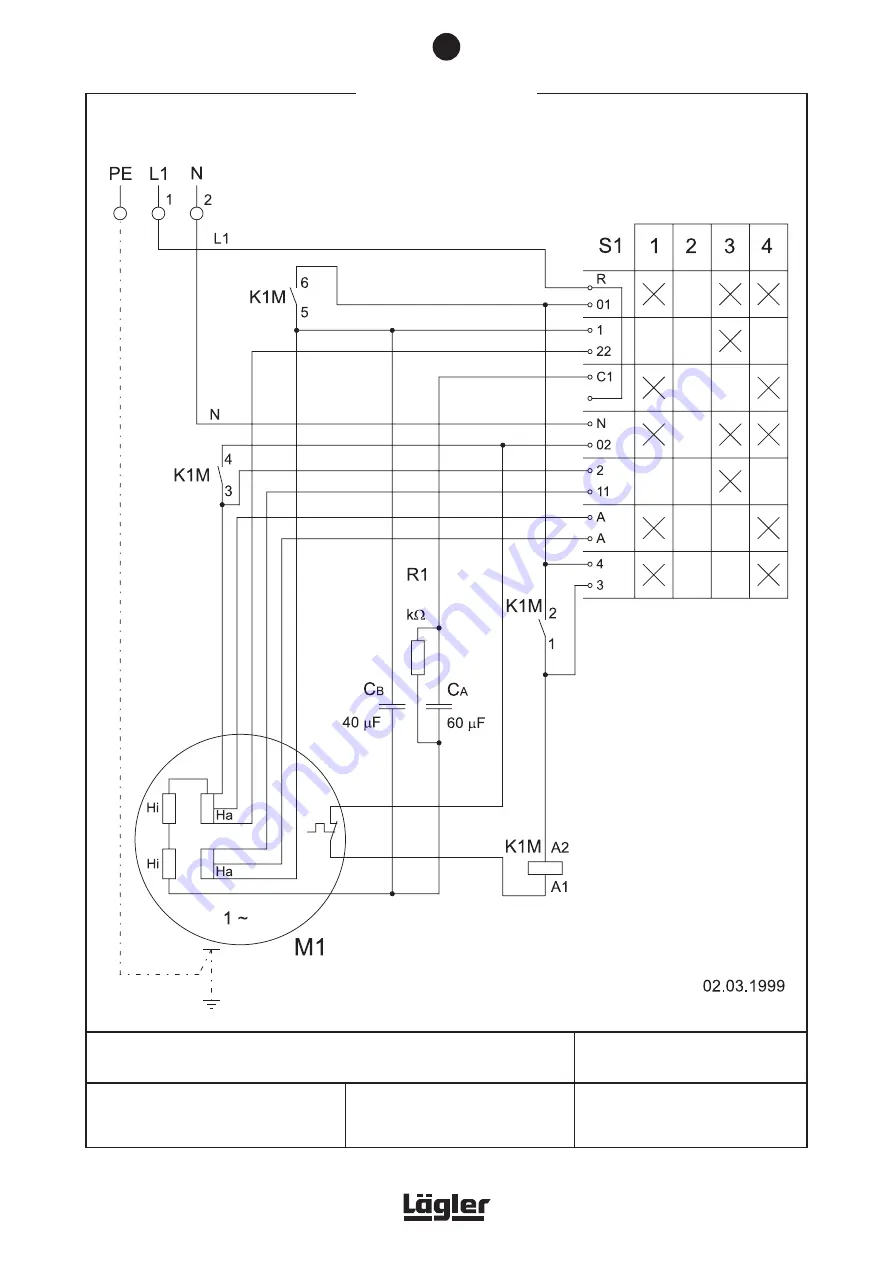

max. back-up fuse: 16 A

power supply: 230 V / 50 CPS

selector switch

test

stop

operation

start

C

A

= starting capacitor

C

B

= running capacitor

Ha = main winding

Hi = auxiliary winding

temperature

switch

operation

motor 2.2 kW

230 V / 50 CPS

The circuit diagram valid for your machine is located in the motor switch box.

8.6

ELF:

2.2 kW / 230 V / 50 CPS

single-phase AC motor

CIRCUIT DIAGRAM

9

EUGEN LÄGLER GMBH

Industriegebiet Kappelrain

D-74363 Güglingen-Frauenzimmern

Telefon: +49 - 7135 - 98 90 - 0

Fax:

+49 - 7135 - 98 90 - 98

E-Mail: info@laegler.com

Internet: http://www.laegler.com

Summary of Contents for HUMMEL

Page 34: ...34 SPARE PARTS 10...

Page 36: ...36 SPARE PARTS 10...

Page 38: ...38 SPARE PARTS 10...

Page 40: ...40 up to May 2000 from May 2000 Please state the machine number with each order SPARE PARTS 10...

Page 42: ...42 SPARE PARTS 10...

Page 44: ...44 SPARE PARTS 10...

Page 46: ...46 NOTES...