SINGLE 01.06.2019

English / Englisch

CAUSES OF FAULTS

9

9.3 THE MACHINE RUNS BUT HAS NO OR VERY

LITTLE SANDING POWER CAPACITY

•

The sanding medium is incorrect or dull and must be replaced.

Section 5.3, Changing the sanding disc

•

At low temperatures: The machine is too cold and must be

heated up to room temperature in a warm room.

•

Cables which are too long or too thin are used for the

electrical connection:

- The power cables have a total length of more than 20 m

(790”).

- The power cables have wire cross-sections which are too

small:

at mains voltage 220 V and 230 V are the wire cross-

sections smaller than 2.5 mm² (0.0039 sq.in.),

at mains voltage 400 V are the wire cross-sections smaller

than 1.5 mm² (0.0023 sq.in.).

This causes of faults lead to a loss of power and are not

allowed for safety reasons!

•

The electrical network is not providing sufficient voltage

(undervoltage). Use a transformer if necessary (e.g. LÄGLER

®

part number 708.00.00.100 for 230 V).

9.4 THE MACHINE VIBRATES INTENSELY AND

RUNS NOISILY

•

The sanding medium is not properly attached to the sanding

plate. The attachment must be corrected.

Section 5.3, Changing the sanding disc

•

The sanding medium is damaged or incorrect and must be

replaced.

Section 5.3, Changing the sanding disc

•

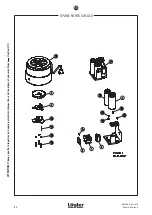

The flexible Velcro ring between sanding plate and sanding

medium is damaged and must be replaced.

•

There are clogged materials and deposits in the machine

that must be removed.

42