UNICO 01.02.2013

English / Englisch

The sanding capacity is not correct

•

Check the V-belt tension

adjust, if appropriate.

•

Check the V-belt condition

renew the belt, if appropriate.

•

Check the machine for clogged-up parts and deposits

clean, if appropriate.

The sanding results are not correct

•

The guide rollers are not correctly adjusted for the respect-

ive attachment

readjust the guide rollers

(Section 4.6,

Adjusting the guide rollers)

.

•

The machine guiding speed is too slow.

•

Circular movements are not being carried with the machine.

•

Excessive pressure is being applied to the sanding disc.

•

Check the abrasive for signs of damage.

•

Check whether the abrasive is fastened in centred position

on the sanding disc wheel

adjust, if appropriate.

9

TROUBLESHOOTING

44

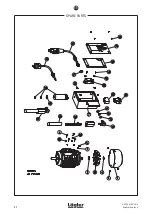

Summary of Contents for UNICO

Page 46: ...UNICO 01 02 2013 English Englisch SPARE PARTS 46 11...

Page 48: ...UNICO 01 02 2013 English Englisch SPARE PARTS 48 11...

Page 50: ...UNICO 01 02 2013 English Englisch SPARE PARTS 50 11...

Page 52: ...UNICO 01 02 2013 English Englisch SPARE PARTS 52 11...