2 & 3 HP Mobile Dust Cyclone Manual

20

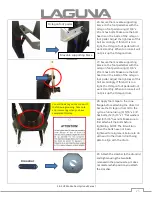

5. (Intake cylinder, cyclone barrel

and cyclone funnel). Install 3 x 6mm

foam tape to rims on each location

shown on the left.

- Top rim of the intake cylinder

- Top rim of the cyclone barrel

- Top and lower rim of cyclone

funnel

6. Attach the intake cylinder to the

dust chute using (4) 5/16”

x

5/8” hex

spring bolts. Then, attach the

cyclone barrel onto the dust chute

using (12) 5/16”

x

3/4” hex bolts and

(12) 5/16”

x18x2t flat washers

followed by attaching the cyclone

funnel to the barrel using (12)

5/16”

x

3/4” hex bolts, (24)

5/16”

x18x2 flat washers and (12)

5/16” hex nuts.

7. Secure the base with (3) lower

upright support panels to the unit using

(6) 5/16” x 3/4” hex bolts and (6) 5/16”

x 1" flat washers.

8. Secure the (3) upright support

reinforcement plates using (12) 5/16” x

3/4” hex bolts and (12) 5/16” x 1” flat

washers.

Summary of Contents for CFLUX2

Page 35: ...2 3 HP Mobile Dust Cyclone Manual 35 Parts Breakdown CFLUX 2 3 Fig 9 ...

Page 36: ...2 3 HP Mobile Dust Cyclone Manual 36 Figure 10 Fan Motor Switch SECTION A Close up view ...

Page 38: ...2 3 HP Mobile Dust Cyclone Manual 38 Figure 12 Panels Lock SECTION C Close up view ...

Page 39: ...2 3 HP Mobile Dust Cyclone Manual 39 Figure 13 Barrel insert SECTION D Close up view 16H 16P ...

Page 48: ...2 3 HP Mobile Dust Cyclone Manual 48 NOTES Ph 800 234 1976 www lagunatools com 100721 ...