Dake Corporation

1809 Industrial Park Dr

Grand Haven, MI 49417

909250

9

REV012021

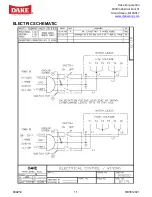

WIRING INSTRUCTIONS

WARNING:

A licensed qualified electrician that follows all state and local laws must

wire and install electrics on this press.

110 Volt

WARNING: Machine must have a designated 30 amp drop for 110 volts. This press

will not operate correctly without 30 amps.

For 110 volts this machine is ready to plug in. The machine can be wired 220-volt single phase.

Always follow the wiring diagram provided in the moor cover when converting to 220-volt single

phase. A cord and plug that is rated for a specific voltage and amperage must be used. This

rating can be found on the motor.

220 Volt Single Phase

The press new is shipped out as a 110-volt machine. If wiring must be changed to suit 220-volt

single phase.

1. The leads on the motor must be changed to fit 220-volt, 17.2 amps, follow the diagram on

the motor.

2. Install plug and wire that fits the rating on the motor, the plug and wire must be rated for

the voltage and amperage listed on the motor.

OPERATION

BEFORE FIRST TIME OPERATION

1. Make sure the reservoir is filled with 3 gallons of Mobil DTE 24 hydraulic fluid or

equivalent.

2. Turn the on/off power (toggle) switch to the “on” position (up).

3. Move the control lever down, this will advance the ram in the downward position.

4. Release the control lever and the ram will stop all movement.

5. Move the control lever to the up position and the ram with move up.

6. When the press is new be sure to move the ram up and down to work out any air that

may be in the system.

WARNING: When using the control lever in pressing operations or to return the ram

stop applying pressure once the handle reaches its positive stop. Applying additional

force on the lever does not increase ram speed and will lead to premature damage of the

valve.