Dake Corporation

1809 Industrial Park Drive

Grand Haven, MI 49417

15

983113

REV112020

ADJUSTMENTS

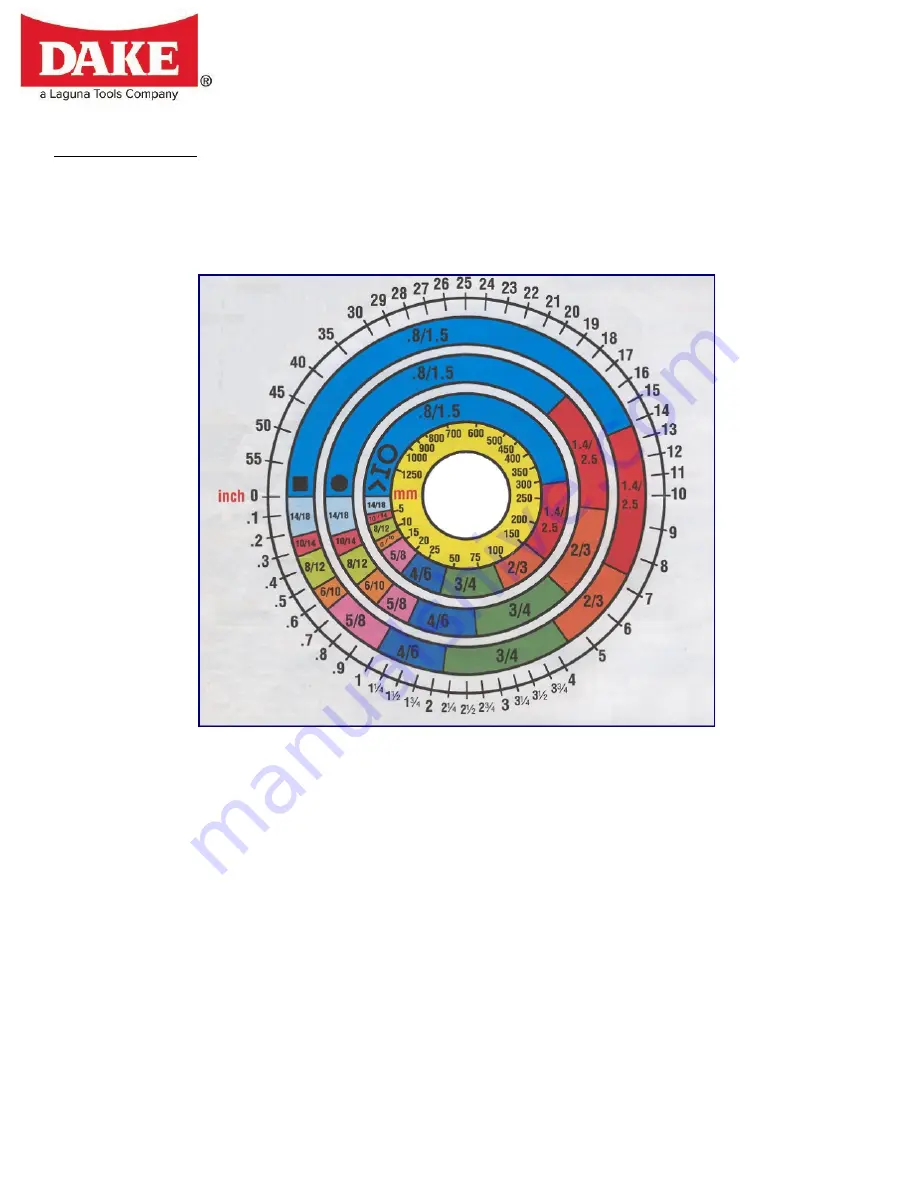

TOOTH SELECTION:

-

For maximum cutting efficiency and lowest cost per cut, it is important to select the blade with

the right number of teeth per inch for the material being cut. The material size and shape

dictate tooth selection.

YOU NEED TO CONSIDER:

The width of the cut. That is, the distance in the cut that each tooth must travel from the point it enters

the work piece until it leaves the work piece, and the shape of the work piece. Use the chart above to

assist with tooth selection.

•

Squares, Rectangles, Flats (Symbol:

■

)

Locate the width of your work piece on the chart. (Inches on the outer circle and millimeters on

the inner circle.) Select the tooth pitch on the ring marked with square which aligns with the

width of the cut.

Example: 6” (150mm) square, use a 2/3 Vari-Tooth.

•

Round Solids (Symbol:

●

)

Locate the diameter of your work piece on the chart. Select the tooth pitch on the ring marked

with the circle which aligns with the size of stock you are cutting.

Example: 4” (100mm) round, use a 3/4 Vari-Tooth.

•

Tubing, Pipe, Structural (Symbols: O, H,

˄

)