Dake Corporation

1809 Industrial Park Drive

Grand Haven, MI 49417

19

983113

REV112020

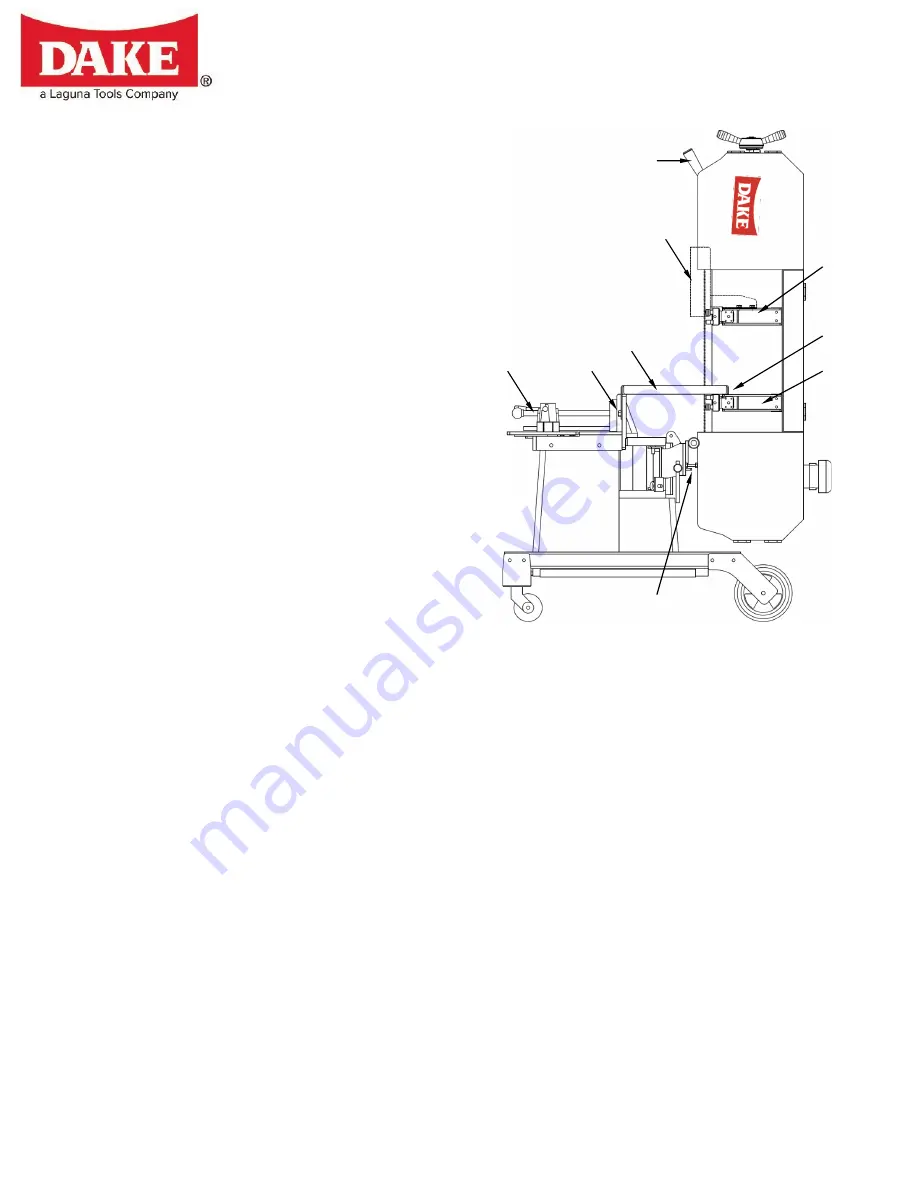

VERTICAL SAW POSITION:

1. Make sure that the moving wheels of the machine

are fixed, and the machine will not move.

2. Close the on-off valve of the hydraulic cylinder and

put the bow on the table with the handle (A), so

that the saw belt is raised to an angle of about 40

degrees with the table.

3. Loosen the spring bracket, remove the fixing screw

of the weight spring, and remove the weight spring.

4. Raise the saw bow again, so that the back end of

the saw bow rests on the upper threaded screw of

(B), and the bandsaw and the workbench are at an

angle of about 90 degrees, as shown in Fig. 3.

Lastly, open the hydraulic cylinder switch valve.

5. Remove the vertical saw blade (C). Insert the cut

groove into the saw belt. Hold saw blade against the

upper end of the fixing vise, fixed with the screw (D). and the position of the saw blade groove

in the middle of the saw blade rear fixed up right board. The main support arm (F) loosen the

handle and adjust the upper and lower positions so that the support arm (F) can contact the

vertical saw board. Press against the surface of point (C), which can maintain the stability of the

vertical saw board in use.

6. Take out the vertical saw cover (H) and fix it on the slave arm (K) with screws to ensure the

safety protection of the exposed bandsaw.

7. Adjust the up and down position from the support arm (K) to match the height of the workpiece

to be sawed.

8. Clamp the vise surface of the vise (G) and fix it so that it will not shake.

9. Check if there is any foreign matter interference on the moving line of the saw belt.

10. After making sure that it is correct, turn on the power and make the saw belt run at the slowest

speed to see if there is any noise or intervention.

11. When the saw belt can rotate normally, the normal, vertical saw cutting pin can be started.

A

H

K

C

E

G

D

F

B