Dake Corporation

1809 Industrial Park Drive

Grand Haven, MI 49417

20

983113

REV112020

SAW ADJUSTMENTS

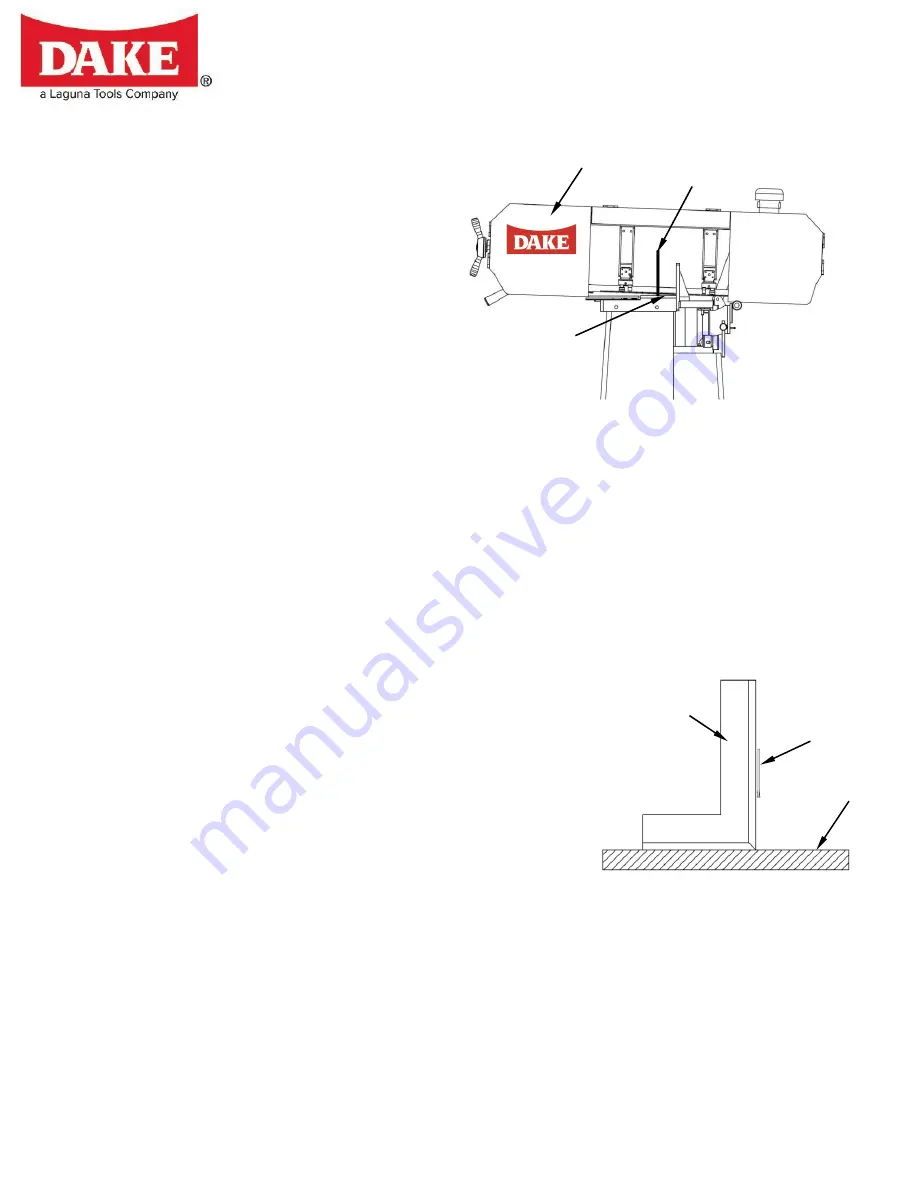

1. Raise the saw to the upward position and

the bandsaw roughly ½” high from the

workpiece as shown in (Fig. 4).

2. Remove the 90

º

angle ruler (C) and lean it

against the workpiece surface.

3. Check the saw belt (B) is perpendicular to

the work piece. NOTE: (If the deviation is

large, you can adjust the blade guides

accordingly).

4. First make sure that the bearings (F) and

(G) are in close contact with the bandsaw

surface. (Note: Visually, the bearing surface and the bandsaw surface are in close contact.

Once the bearing can still be rotated freely, it is to ensure that the bearing is not crushed. ,

Easy to cause damage).

5. Adjust the bearing shaft. It can be adjusted with a slotted screwdriver (H) and fixed with a

hexagon wrench (M). (Fig. 6) (Fig. 7)

6. Adjust the bandsaw 90 degrees, you can put the hex wrench (K) to loosen the screw, use the

hex wrench (I) to adjust 90 degrees, and the hex wrench (J) to adjust the gap between the

back of the bandsaw and the upper bearing After finishing the fine adjustment, fix the screw

lock with the hexagon wrench (K). NOTE: (It is necessary

to check and adjust the 90-degree angle between the main

block and the two positions from the guide block at the

same time)

7. The slowest speed of the saw belt can be performed after

the completion to ensure that the rotation of the saw belt

does not cause problems involving abnormal sounds, and

check whether the upper bearing and the back of the saw

blade only maintain proper contact without crushing.

8. After the saw belt has been tested correctly, the tungsten

steel guide block (O) can be fixed on the guide block (C)

with screws (P) to improve the stability of the saw belt when it rotates. (Note: The gap between

the tungsten steel guide block and the saw blade surface must be about 0.1mm (about 1 sheet

of paper) to prevent the tungsten steel from directly scratching the saw blade surface and

causing damage)

A

C

B

C

B

D

Figure 4

Figure 5