Dake Corporation

1809 Industrial Park Drive

Grand Haven, MI 49417

22

983113

REV112020

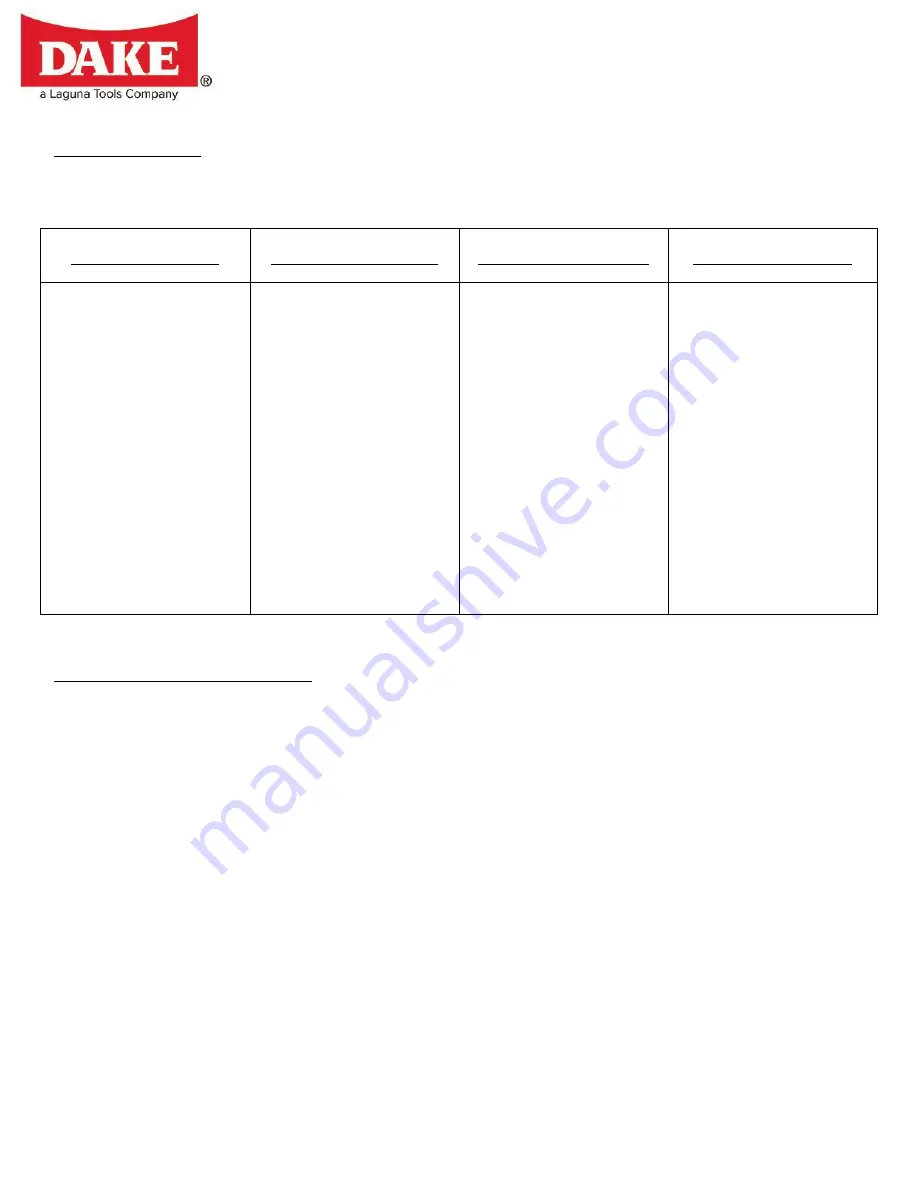

MAINTENANCE

-

Below is a useful maintenance reference to use that can be repeated throughout the year to

keep up to date on general maintenance for your machine.

Daily Maintenance

Weekly Maintenance

Monthly Maintenance

Yearly Maintenance

1) Fill the lubricant

before starting the

machine every day.

2) If the temperature of

the spindle is

overheating, or

making a strange

noise, shut down the

machine immediately

and check it for

accurate

performance.

3) Keep work area

clean.

1) Clean and coat the

cross leading screw

with oil.

2) Check all sliding

surfaces, pivoting

points, and turning

parts to see if any are

lacking any

lubrication. If they are

lacking lubrication, fill

it.

1) Adjust the accurate

clearance both

vertical and

horizontal feed.

2) Lubricate bearings,

worm shaft, and

worm gears to avoid

long term wear.

1) Adjust the horizontal

position of the table

for accuracy.

2) Check electric plug,

cord, wires, and

switches to avoid

long term wear once

a year.

LUBRICATION & CLEANING

1) Your machine has been coated heavy grease to protect it in shipping. This coating should be

completely removed before operating the machine. Commercial degreaser, kerosene or similar

solvent may be used to remove the grease from the machine but avoid getting solvent on belts

or other rubber parts.

2) Be sure to clean. The band saw after operation. And coat this machine with rust-less oil. And

clean the iron filings of the roller grooves of the rotating seat to avoid the rust and the damage

caused by the rolling of the bearing.

3) Use SAE-30 oil to lubricate the components.

4) Lubricate the vise lead screw if needed to do so.

5) The driving gears will not require a lubricant change more often than once a year, unless of a

leak or overheating as occurred.