-12-

www.igm.cz

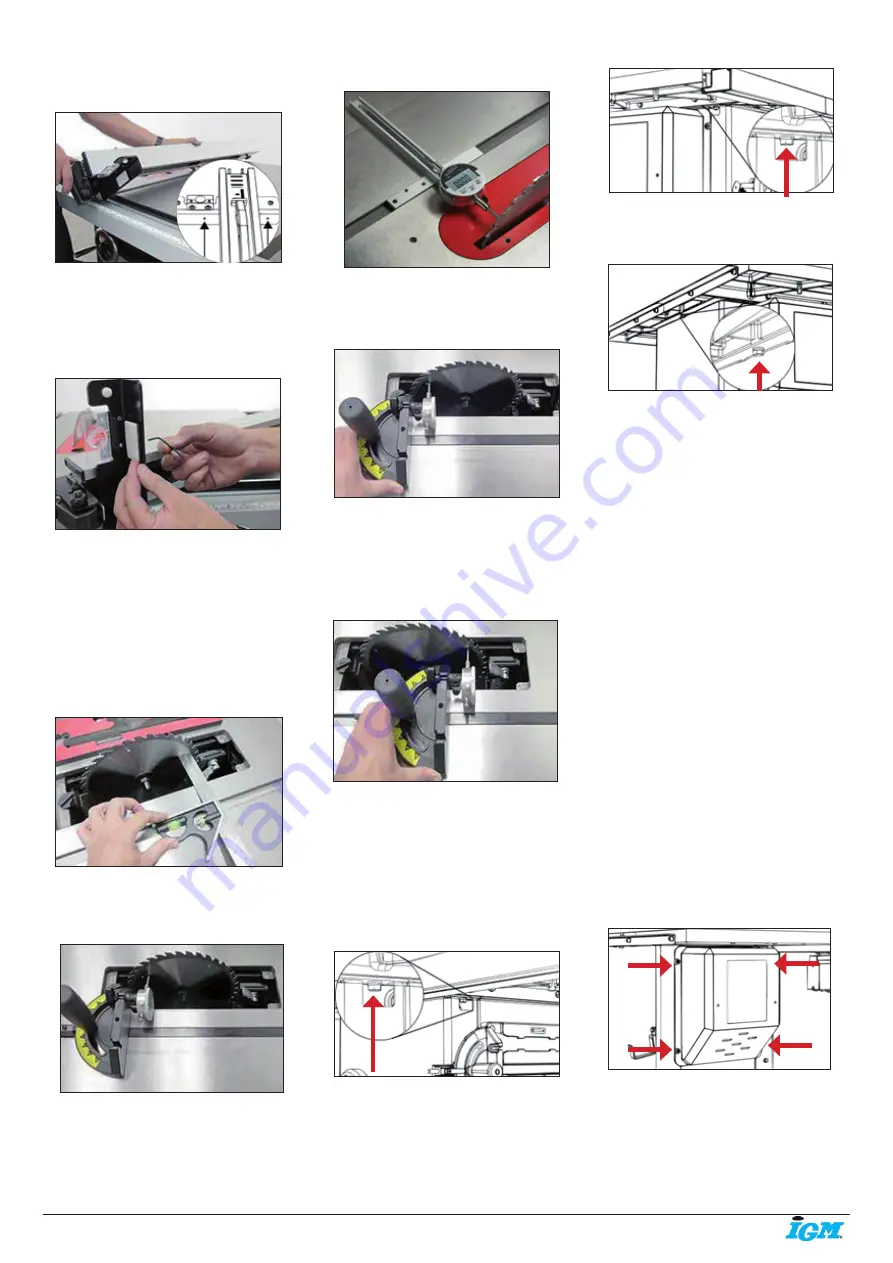

Loosen Table Bolts

Locate and loosen left side table to cabinet bolt

(above the motor cover).

Loosen Table Bolts

Locate and adjust the rear table to cabinet bolt.

Modification and installation of side table

extensions (can already be installed at the

factory):

Follow these steps to achieve a smooth

transition between the extension and the table.

1. Disconnect the saw from the power supply!

2. Attach the guide side rulers.

3. Using a wrench, tighten the side extension

bolts to the side rulers.

4. Align the top edge of the table and the

extension into the plane and screw the screws

into the table.

7.3 Arbor and Tilt Adjustments

Adjusting the Blade Tilt Limits

You can check the arbor (blade) tilt limits with

an angle finder or 45-degree triangle. If these

limits are not within 0 degrees and 45 degrees,

use the following steps to adjust.

1. Unplug the table saw!

2. Remove the motor cover.

3. Remove the tool storage cover.

4. Locate tilt adjustment screws.

5. Adjust as needed.

6. Adjust the scale and indicator as needed.

Use caution: From the factory, the tilt limits

are pre-set to 0 and 45 degrees tilt to the left.

Adjusting this limit will slightly alter that amount

which may cause throat plate or fence to

interfere. Adjusting these limits should only be

done to set the tilt limits to 0 and 45 degrees.

2. Remove motor cover

WARNING: MAKE SURE SAW IS

UNPLUGGED.

To access the left side tilt limit adjustment

screw, remove the motor housing cover using

a #2 Philips head driver. There are 4 screws in

total holding on the motor cover.

A dial indicator on a mitre gauge.

Best

A dedicated saw dial indicator. Such as this one

by ‘Iagging’.

1. Un-plug the tablesaw!

2. Take initial measurement.

WARNING: MAKE SURE SAW IS

UNPLUGGED. With the throat plate and all

attachments removed, raise the blade to the

highest position at 90 degrees with the table.

Take an initial measurement about 1 cm from

the ground edge of the blade as shown.

3. Take relative measurement

Keep the mitre gauge against the left rail

and slowly move crossed the blade. Take

the second measurement and compare with

the initial measurement. Adjust the table to

compensate false measurements. There are 3

bolts to loosen prior to adjusting the table, see

step 4.

4. Loosen the three table fastener bolts.

5. Adjust as needed.

Loosen Table Bolts

Locate and loosen right side table to cabinet

bolt (above the tool holder).

adjustments to make the fence parallel to the

saw blade prior to operation.

Position fence to access adj. screws

WARNING: MAKE SURE SAW IS

UNPLUGGED. Take the fence out of position

and flip it on its back side to access the cat

screws that push the nylon supports in/out.

Use a hex key to adjust

Use the included hex key to adjust the depth of

each nylon support. Do small increments and

check.

7.2 Table Adjustments

Adjusting the Table to be Parallel with the

Blade: It is good practice to make sure that the

table is always parallel to the blade by checking

it often. You can do this with a combination

square or with a dial indicator on an appropriate

mount. Check the IGM website for these tools.

Good

Combination Square. Notice: This method may

leave scratched.

Better