-14-

www.igm.cz

at least 2mm beneath the topmost tooth.

The riving knife must be at least 0.2 mm thicker

than the main saw blade.

Check that the saw blade clamping system is

tight before operating the machine!

Dust Collector:

There is a 100 mm dust outlet located on

the lower left of the saw cabinet allowing for

the connection to a dust collection system

(not included). Air current speed is 20m/s for

vacuum suction dust emission index. When

air current speed of dust collector device (in

accordance with EN 12779:2004+ A1:2009) is

not lower than 20m/s, ensure machine can be

normal exhausted. User must wear dustproof

mask.

1. Fit the 100 mm dust hose over the dust port,

(not included) and secure in place with a hose

clamp.

2. Make sure the hose could not come off.

3. Required air flow: 934 m3/h

4. Ensure pressure drop of each dust collector

outlet carrying air current speed: 1500Pa

5. Wind speed of dust collector tube m/s: dry

chips: 20m/s, water content is equal to18% wet

chips: 28m/s.

Warning: Always turn on the dust collector

before starting the saw and stop the saw before

turning off the dust collector.

Note.: A tight fit is necessary for proper

performance.

Warning: Always turn off the table saw before

removing any cover of the machine.

Remove the side cover, to clean and remove

dust, debris from dust hood.

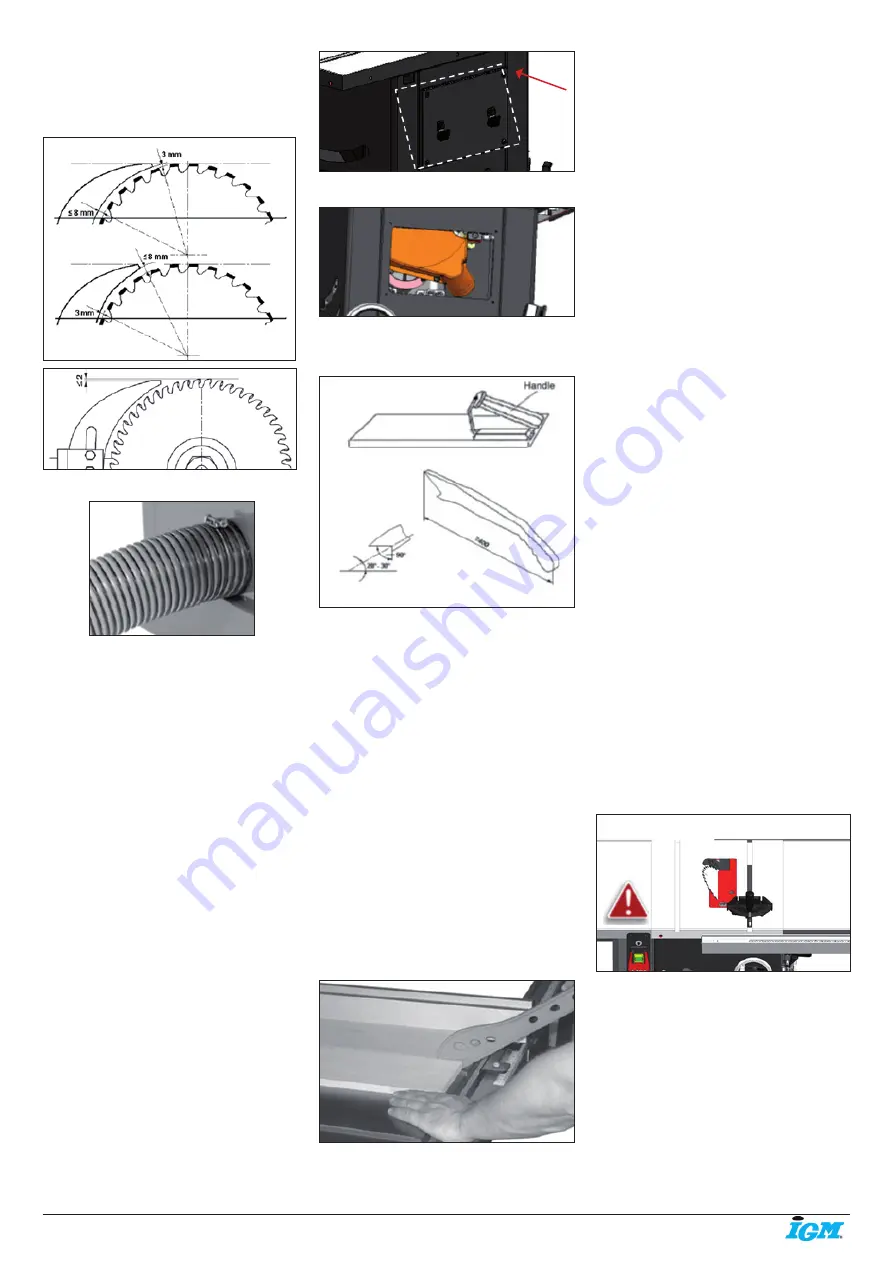

7.5 Push block and push stick

A push block (Pic.2) and A push stick (Pic.3)

must be used.

If the workpiece is less then 12 0mm, you must

use the push stick to prevent your hands from

getting too close to the saw blade.

Push block must be used to cut narrow

workpieces and, when necessary, to push the

workpiece against the fence, a push block can

be easily made by the operator as Pic.

Warning: Use only the push stick provided by

the manufacturer or constructed in accordance

with the instructions. This push stick provides

sufficient distance of the hand from the saw

blade.

Warning: Never use a damaged or cut push

stick. A damaged push stick may break causing

your hand to slip into the saw blade.

8. Type of Cut

Warning: Always wear safety glasses, a

respirator and hearing protection when

operating this machine.

Note: This saw is only designed to cut wood.

8.1 Ripping

Cutting a wood plank or sheet of plywood

lengthwise to reduce its width is called “ripping”.

To rip stock, hold the work with both hands

pushing it into the blade as well as firmly

against the rip fence so that it is cut straight.

• Never rip or cut wood without using the fence

or mitre gauge to guide it because the stock

could kickback.

• Always use the blade guard and riving knife

assembly when cutting wood. The riving knife

prevents the saw “kerf” (the slit cut by the

blade) from closing and binding the blade,

which can overload and/or stall the motor or

cause the blade to lift and eject the workpiece

towards the front of the saw at very high

speeds. The blade guard keeps your fingers

away from the blade and also reduces the

amount of sawdust flying free.

• Some jobs may require removing the riving

knife along with the cover. Do not forget to put

them back when you are done.

As you complete the rip, the wood will either

remain on the table, tilt up to be caught on

the end of the guard, or fall onto the floor (or

outfeed table). The waste part of the stock

remains on the table to be removed only after

the saw is stopped (unless it is large enough for

immediate safe removal).

If the work to be ripped is narrow, it is safer

to use a push stick, rather than the hands, to

feed it into the blade Push sticks with non-slip

grippers can be purchased, but a shop-made

one works just as well. When ripping extremely

narrow stock that may not clear the width of

the blade guard, or very thin material such

as panelling, which may slip between the

underside of the fence and the table surface,

a strip of wood as an auxiliary guide can be

attached to the fence.

WARNING: Keep the blade guard installed and

in the down position. Failure to do this could

result in serious personal injury or death.

WARNING: Never reach in towards the blade

while the blade is still spinning! whenever a rip

cut is completed, turn off the saw and wait for

the blade to come to a complete stop before

reaching in to remove the workpiece or the

waste material.

8.2 Bevel Ripping

Bevel ripping is performed the same as ripping

but with the saw blade set to an angle not

perpendicular with the table surface. To tilt the

blade to the left, anywhere between 0° and 45°.

This is used most often when cutting bevels,

compound mitres or chamfers.

After changing the bevel angle verify the

alignment of the guard and splitter; make sure

there is clearance with the saw blade.