-4-

www.igm.cz

Contents

1. Declaration of conformity

1.1 Warranty

2. About this manual

3. Fusion 3 Specifications

3.1 Contents

3.2 Technical

3.3 Main Features

4. General Safety

4.1 Intended Use

4.2 Work Area

4.3 Personal Safety

4.4 Tool Use

4.5 Guarding Related Warnings

4.6 Work Related Warnings

4.7 Kickback Causes and Related Warnings

4.8 Table Saw Operating Prodedure Warnings

4.9 Electrical

4.10 Noise emissions

4.11 Grounding

4.12 Rulings

4.13 Notice on safe use of the machine

5. Machine overview

5.1 Controls

6. Setup

6.1 Receiving and unpacking

6.2 Inventory

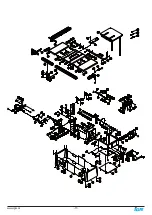

6.3 Loose parts & overview

6.4 General setup

6.5 Installing/removing the throat plate

6.6 Installing/removing safety accessories

6.7 Installing/removing the blade

7.

Adjustments

7.1 Fence adjustments

7.2 Table adjustments

7.3 Arbor and tilt adjustments

7.4 Accessory adjustments

7.5 Push block and push stick

8. Type of cut

8.1 Ripping

8.2 Bevel ripping

8.3 Ripping small workpieces

8.4 Cross cutting

8.5 Bevel cross cutting

8.6 Mitre cuts

9. Maintenance

9.1 Internal Components Map

10. Trouble-shooting

1. Declaration of conformity

We declare that this product is in compliance

with the directive and the standard mentioned

on the 2. page of this manual.

1.1 Warranty

IGM Tools & Machinery strives to always

deliver high-quality machinery. The warranty is

governed by the valid terms and conditions of

IGM Tools & Machinery available at

www.igmtools.com.

2. About manual

This manual is intended to thoroughly cover the

setup up, maintenance, and proper adjustments

of your new purchase. Aside from the

proceeding general safety considerations,

this manual DOES NOT cover woodworking

or metalworking techniques that are possible

with this product and the appropriate safety

precautions necessary for safe practices. There

are several organizations with published safe

practices, techniques, and proper operation of

this tool. Or look for handy tips and instructions

at www.igmtools.com.

3. Fusion 3 specifications

3.1 Contents

Professional Square Zero Clearance Throat

Plate (pre-installed)

250 mm Saw Blade (pre-installed)

Riving Knife (pre-installed)

Mitre Gauge (ships in tool holder)

Tool Holder (pre-installed)

Fence

Blade Guard

Arbor Wrench

Installation and Adjustment Tools

3.2 Technical Data

Power

230V / 50 Hz / 1 Phase

Motor Type

TEFC Capacitor Start AC Induction

Power Input

2200 W

Motor Speed

2850 /min-1

Full Load Amperage

14.5 A

Start Capacitor

400 µF-U

Run Capacitor

50 µF-U

Switch Type

Magnetic with Overload Protection

Power Transfer

Single V-Ribbed 142J FJ

Power Cord

2 m / H07RNF

Power Plug Included

CEE 7/7

Breaker Recommendation

16 A,

tripping characteristic C (16/1/C)

General

Footprint (LxW)

503 x 520 mm

Overall Dimensions (LxWxH)

1663 mm x 1652 mm x 1081 mm

Shipping Dimensions (LxWxH)

1130 mm x 1100 mm x 1190 mm

Weight (No Accessories)

157 Kg

Shipping Weight:

202 Kg

Dust Collection: Outlet Dia.

101.6 mm

Dust Collection m3/h, min.

934 m

3

/h

Sound Emissions

N/A

Specifics

Blade Diameter

250 mm

Bore Diameter

30 mm

Arbor Speed

3800 /min-1

Blade Rotation

Counter-Clockwise

(face arbor)

Rip Capacity, with Fence

914,4 mm Right (1 320,8 mm w/ accessories)

Max. Depth of Cut 90°

79 mm

Max. Depth of Cut 45°

56 mm

Blade Tilt

45° Left, 3° Arbor Adjustment

Table Dim., with Extensions (LxW)

1117 mm x 1663 mm

Wing Dimensions (LxW)

792 x 305 mm

Mitre Slot

19 and 23 mm, T-Slot

Fence Type

Sliding Cam Action Fully Adjustable

Fence Dim (LxWxTh.) 670 x 80 x 17 mm

Throat Plate Type

Zero Clearance

Throat Plate (LxWxTh.) 372 x 104.5 x 13 mm

Floor to Table Height 887 mm

3.3 Main Features

• Robust cast-iron trunnion.

• Sheet metal control wheels.

• Two T-slots on the side of the blade.

• Smooth control of the blade height and tilt.

• Lever for a quick blade swap.

• Adjustable control panel.

• Quick clamping riving knife.

• Integrated wheel for simple mobility.

• Includes rear table.

4. General Safety

Warning: Read all safety considerations. Failure

to follow this set of guidelines can result in

unwarranted damage to the machine and serious

injury to the operator and bystanders. Save all

warnings and instructions for future reference.

4.1 Intended Use

• Table saw and the workpiece guide equipment

supplied with it are intended to be used

exclusively for the following purposes:

- Laminated and non-laminated board materials

(e.g. chipboard, coreboard, MDF board,...)

- Solid wood

- Gypsum plasterboard, Cardboard, Veneer with

a suitable clamping device

- Dimensionally stable plastics (thermoset

plastics, thermoplastics).Sawing these materials

does not normally involve any risks in respect of

dust, chips, and thermal degradation products.

Tools:

EN - English

Operating Instructions

Dear Woodworker,

Thank you for your purchase and welcome to the Laguna Tools group of discerning woodworkers. We understand that you have a

choice of where to purchase your machines and appreciate the confidence you have in the Laguna Tools brand.

Every machine manufactured by Laguna Tools has been carefully designed and well thought through from a woodworker’s perspective.

Through hands-on experience, Laguna Tools is constantly working hard to make innovative, precision products. Products that inspire

you to create works of art, are a joy to run and work on, and encourage your performance.