-8-

www.igm.cz

any of the following steps, installations, or

adjustments with the saw connected to the

power source.

Warning: To avoid set-up problems, to prevent

potential damage to the machine and personal

injury, read through the entire setup section

prior to setting up the machine.

6.1 Receiving and unpacking

If any damage has occurred because of

shipment, note the damage on the bill of lading

or refuse the shipment. Immediately call the

dealer store where the machine was purchased.

TRANSPORTATION AND STORAGE. The

measures of anti-rust and shockproof should

be taken during packing. The machine endures

transportation and store in -25~55°C ambient

temperature.

Be careful not to expose the machine to rain or

damage when transporting or storing.

While transporting or handling the machine,

be careful and let the activity be done by

qualified personnel especially trained for

this kind of activity!

While the machine is being loaded or

unloaded, make sure that no person or

subject gets pressed by the machine!

Select proper transportation device

according to the weight of the machine.

Make sure the lifting capacity of

transportation device is competent for the

weight of the machine.

TRANSPORTATION BEFORE UNPACKING

The machine is packed in a large box as

standard. Machine for easy transport of the

machine and packaging.

UNPACKING

1. Receive your table saw.

2. Open the cardboard box.

3. Check all components.

4. Wipe off protective oils.

1. Magnetic switch

2. Overload protector

3. Fuse

CAUTION: Always turn off and unplug the

machine before changing the fuse.

Arbor height control

The shaft height adjustment adjusts the height

of the cut.

Arbor tilt control

The disc tilt control is on the right side of the

cabinet. Clockwise left, counterclockwise.

Fence clamp lock

The fence clamp securely locks the fence

anywhere on the rail by a cam action

mechanism.

6. Setup

Use Caution: Your new Laguna Tools machine

is heavy. Use a minimum of two people when

lifting the tool into position and moving the tool

into position.

Warning: DO NOT connect to a power supply

until the setup is complete. DO NOT perform

Receiving your tablesaw

This is how machine is shipped from the factory.

The saw comes with accessories in boxes.

Note: The insert and the saw blade are already

installed on the saw. Other accessories (angle

ruler, wheel release key) are in the box or on

the side of the cabinet.

1. Fence, install tools, push stick, blade guard

assembly

2. Smaller fence rail sections, hardware kit

3. Longer fence rail sections.

Wipe off protective plastics

Peel back the protective vinyl plastic and wipe

away the oil with a waste rag.

Use Caution: An oily rag can be a serious fire

hazard. Discard in an appropriate manner.

Tech Tip: To help keep your table top clean and

to prevent or clean any rust, we recommend

waxing your tabletop with an appropriate wax

rubbing compound. This will also reduce friction

under operation. Rust can be removed with

WD-40.

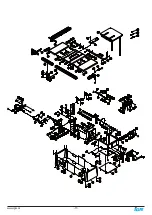

6.2 Inventory

Fence

Push stick

Blade guard

Install Tools

Fence hooks*

* Fence storage hooks may be pre-installed.

Rear Rail 2

Front Rail 2

Hardware kit

Rear rail 1

Front rail 1

Pre-installed on machine

Throat plate

Riving knife

250mm blade

Mitre gauge

Arbor wrench

Tool storage

Wings (2x)

Note.: The front rail part number is comprised of

two pieces – both long and short. The rear rail

part number is comprised of two pieces – long

and short.

Note.: For safety reasons, this machine is not

sold with a tape-rule for the left side of the

blade. It is not a missing part.