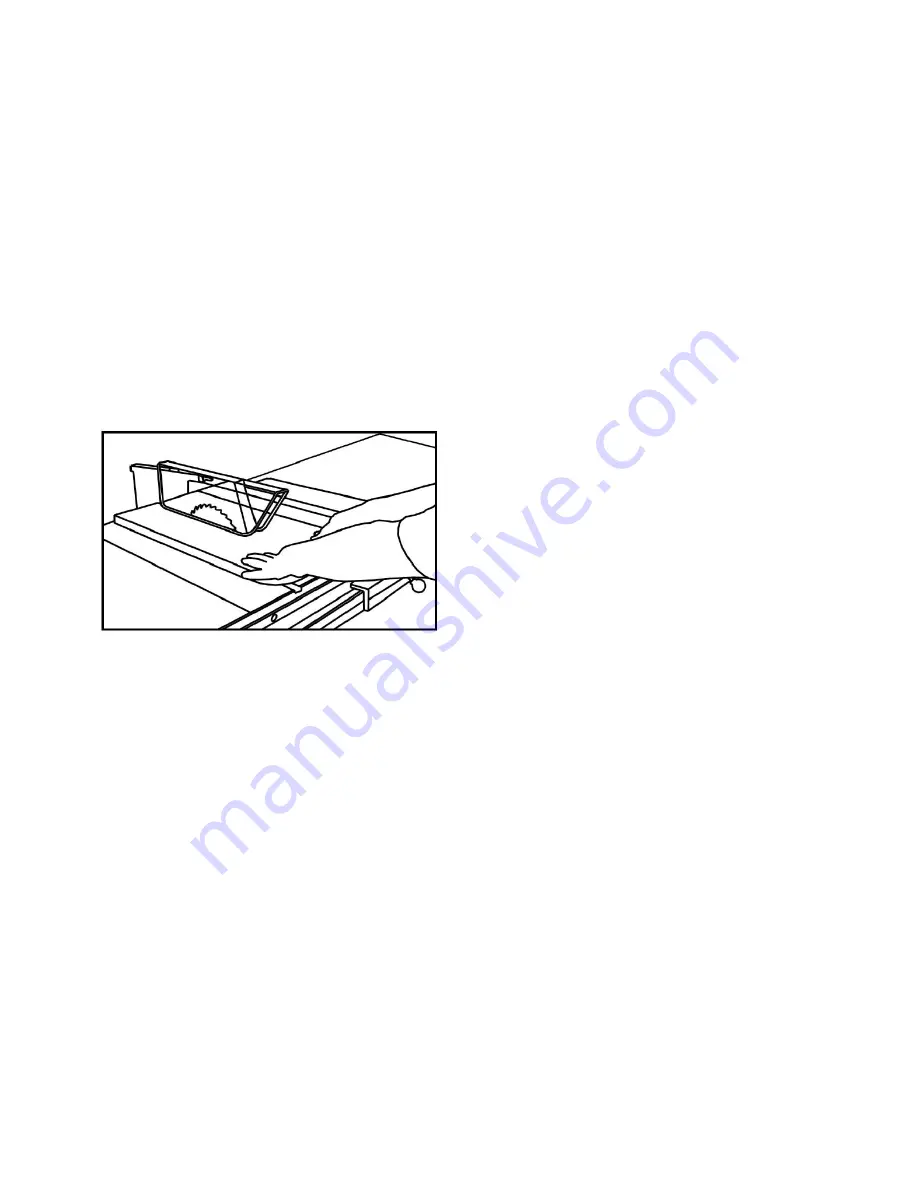

saw blade as shown in Fig. The work can then be

fed through the saw blade with one or two hands.

When this is done the work will either stay on the

table, tilt up slightly and be caught by the rear end

of the guard or slide off the table to the floor.

Alternately, the feed can continue to the end of the

table, after which the work is lifted and brought

back along the outside edge of the fence. The

waste stock remains on the table and is not

touched with the hands until the saw is stopped

unless it is a large piece allowing safe removal.

Fig.31

8. Maintenance

This table saw requires very little maintenance

other than minor lubrication and cleaning. The

following sections detail what will need to be done

in order to assure continued operation of your saw.

LUBRICATION

The table saw has sealed lubricated bearings in

the motor housing and the arbor assembly, they

will not require any additional lubrication. Use a

wire brush to clean off the worm gears and

trunnions and apply a white lithium grease to keep

them lubricated

CLEANING

Cleaning the Model is relatively easy. Vacuum

excess wood chips and sawdust, and wipe off the

remaining dust with a dry cloth. If any resin has

built up, use a resin dissolving cleaner to remove it.

After cleaning, treat all unpainted cast iron and

steel with a non-staining lubricant.

Occasionally it will become necessary to clean the

internal parts with more than a vacuum. To do this,

remove the table top and clean the internal parts

with resin/pitch dissolver or mineral spirits and a

stiff wire brush or steel wool.

Make sure the internal workings are dry before

using the saw again, so that wood dust will not

accumulate. If any essential lubrication is removed

during cleaning, re-lubricate those areas.