19

Maintenance.

As with any machine, to ensure optimal performance, you must conduct regular

maintenance.

Daily checks.

1.

Clean the machine and lubricate unpainted surfaces with a Teflon-based

lubricant. Wipe off any excess and buff with a dry polishing cloth. This will reduce

the likelihood of rust forming and reduce the friction on the tables as the wood is

machined.

2.

Check cutter blades for chips and dullness.

3.

Generally inspect the machine for damage and loose or warn parts.

Weekly checks.

1.

Clean the cutter head.

2.

Check cutter blades for chips and dullness.

3.

Generally inspect the machine for damage and loose or worn parts.

4.

Check the dust extraction for blockages and any large bits that could cause

blockages.

Monthly checks.

1.

Check the motor drive belts for wear, splits and cuts.

2

. Clean the motor compartment and the motor to ensure that the motor cooling fins

work efficiently.

3.

Clean and lubricate the drive chains and cogs.

4.

Generally inspect the machine for damage and loose or worn parts.

Note.

It is recommended that you use a Teflon-based lubricant.

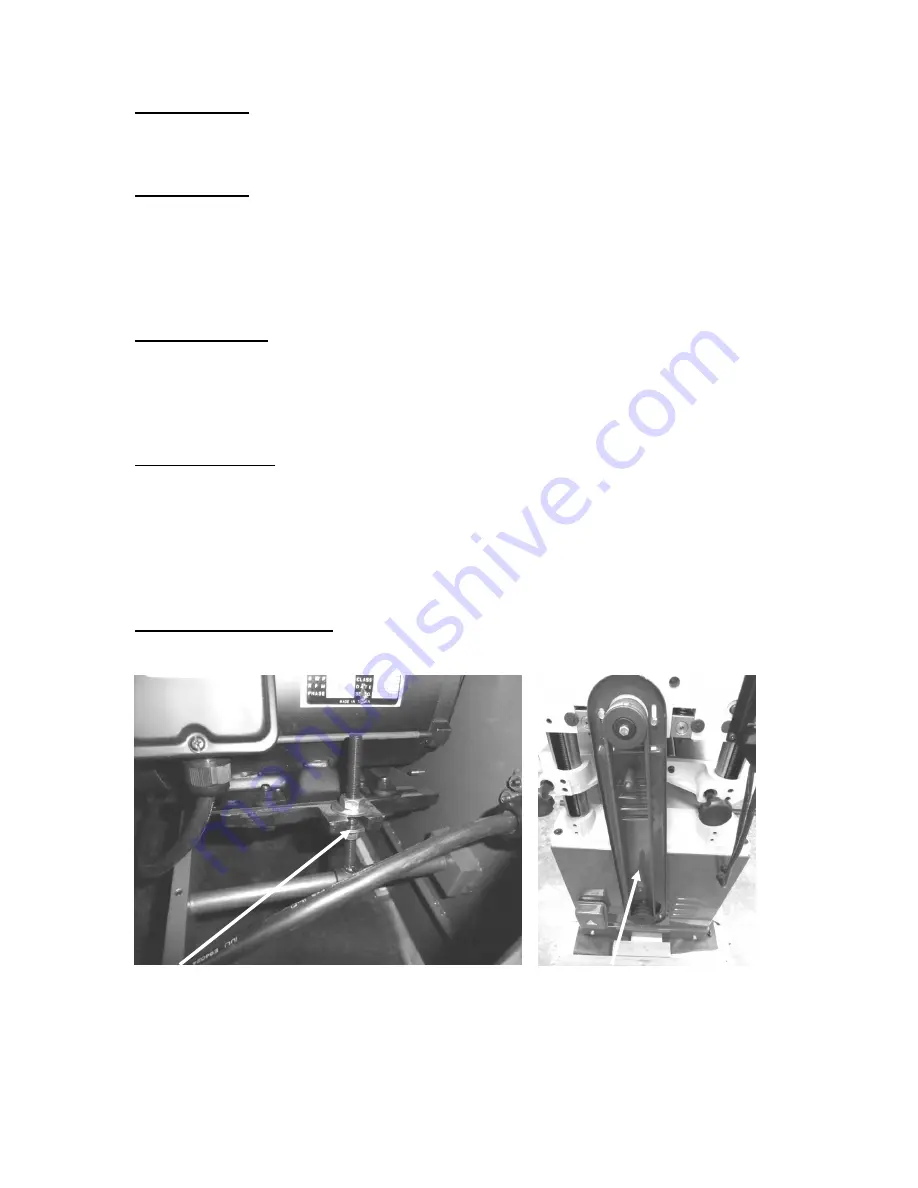

Drive belt replacement.

Note.

Disconnect the power to the machine before conducting any maintenance on

the machine.

Motor adjustor

Cover removed

Summary of Contents for MPLAN1510-0120

Page 2: ......

Page 25: ...25 Exploded view drawings...

Page 26: ...26...

Page 27: ...27...

Page 28: ...28...

Page 36: ...36...

Page 37: ...1 Laguna Tools MPLAN1510 0130 Platinum Series 16 Planer...

Page 61: ...25 Exploded view drawings...

Page 62: ...26...

Page 63: ...27...

Page 64: ...28...