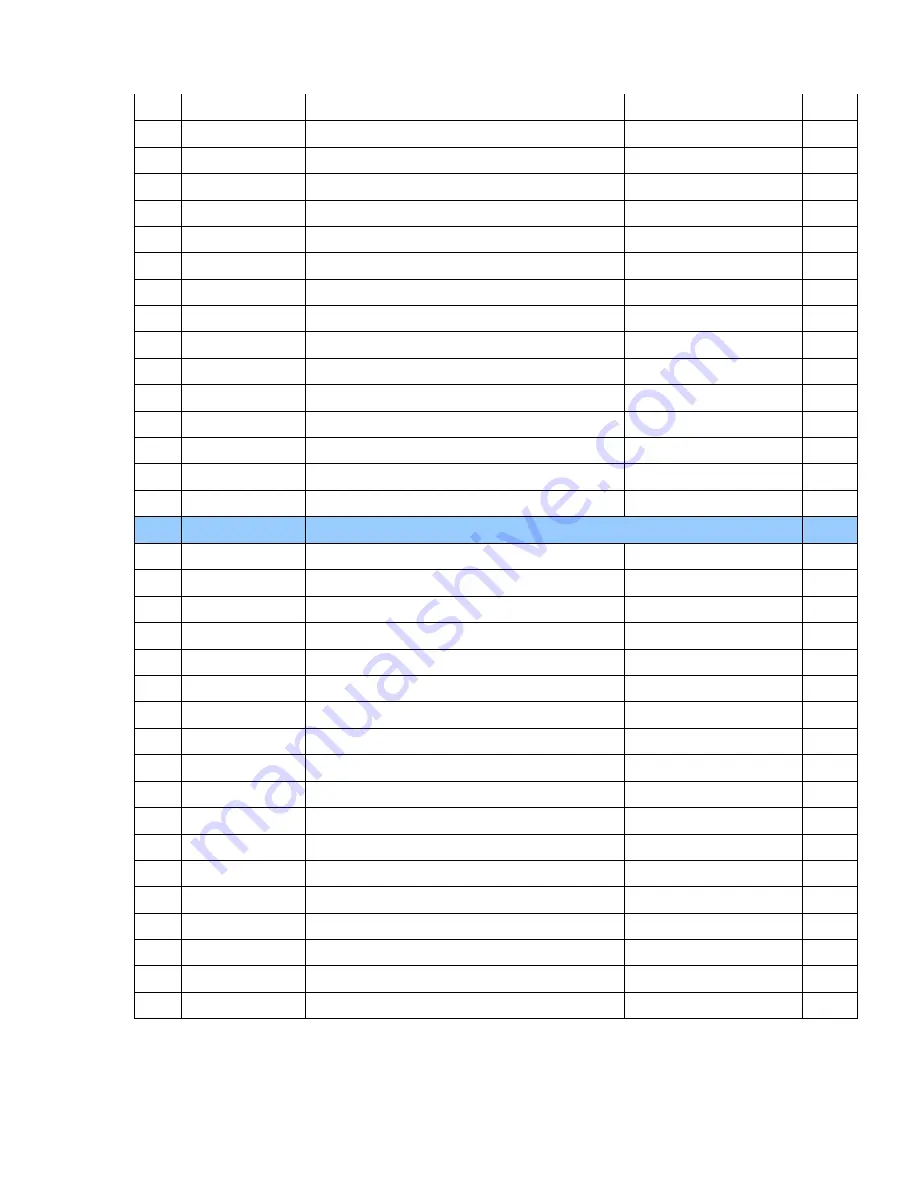

34

156

010006-000

RETAINING RING

STW-15

1

157

000003-205

HEX. SCREW

M8*1.25P*25

2

158

030305-000

BALL BEARING

6202Z(A)

4

159

010103-000

RETAINING RING

RTW-35

4

160

150012-000

CHAIN SPROCKET

4

161

006001-078

FLAT WASHER

10.5*19*1.5t

4

162

008008-100

HEX NUT

M10*1.25P

4

163

250173-000

EXPANSION BEND

8

164

001104-502

ROUND HEAD TAPPING SCREW

M5*2.12P*10

30

165

170481-901

FIXING BUSH

16

166

050298-000

MAIN COLUMN

1

167

010202-000

RETAINING RING

ETW-17

4

168

360396-902

ROD

4

169

320203-000

WORM GEAR

1

170

010104-000

RETAINING RING

RTW-38

1

171

130046-000

BUSHING

1

Key

Part No.

Descriptions

Q'ty

172

012002-004

KEY

4*4*10

2

173

360397-000

ELEVATING SCREW

1

174

040003-000

HEX. WRENCH

3mm

1

175

040004-000

HEX. WRENCH

4mm

1

176

040005-000

HEX. WRENCH

5mm

1

177

040006-000

HEX. WRENCH

6mm

1

178

040201-000

WRENCH BOX

8*10

1

179

040204-000

WRENCH BOX

12*14

1

180

040206-000

WRENCH BOX

17*19

1

188

050299-000

ROLLER BRACKET

3

189

360398-902

ROLLER

2

190

050300-000

ELEVATING SCREW GEARBOX

1

191

000103-113

SOC HD CAP SCREW

M6*1.0P*50

3

192

320204-000

SHAFT

1

194

190008-901

SPACER

1

200

000902-203

HEX SCREW W/WASHER

M6*1.0P*16

5

201

000103-102

SOC HD CAP SCREW

M6*1.0P*10

2

204

003005-206

HEX. SCREW

3/8"-16NC*2-1/2"

4

Summary of Contents for MPLAN1510-0120

Page 2: ......

Page 25: ...25 Exploded view drawings...

Page 26: ...26...

Page 27: ...27...

Page 28: ...28...

Page 36: ...36...

Page 37: ...1 Laguna Tools MPLAN1510 0130 Platinum Series 16 Planer...

Page 61: ...25 Exploded view drawings...

Page 62: ...26...

Page 63: ...27...

Page 64: ...28...