14

Maintenance

WARNING!

Disconnect the machine from power source

before proceeding with any maintenance,

lubrication or assembly! Failure to comply

may cause serious injury!

Periodic, or regular inspections are

required to ensure that the machine is in

proper adjustment, and that all hardware is

tight.

Clean out-feed rollers and table with a non-

flammable solvent to remove pitch, gum

and other unwanted build-up.

Periodically clean the inside of the machine

for dust control.

Keep pulleys and belts free from dirt, dust,

oil and grease. Replace worn V-belts as

needed.

There are three limit switches on the planer,

one that triggers if the hood is open, and a

raising and a lowering limit switch to

prevent the table from automatically

traveling too far. Keep these clean and

blown out with an air hose.

Lubrication

Add a few drops of medium weight oil to

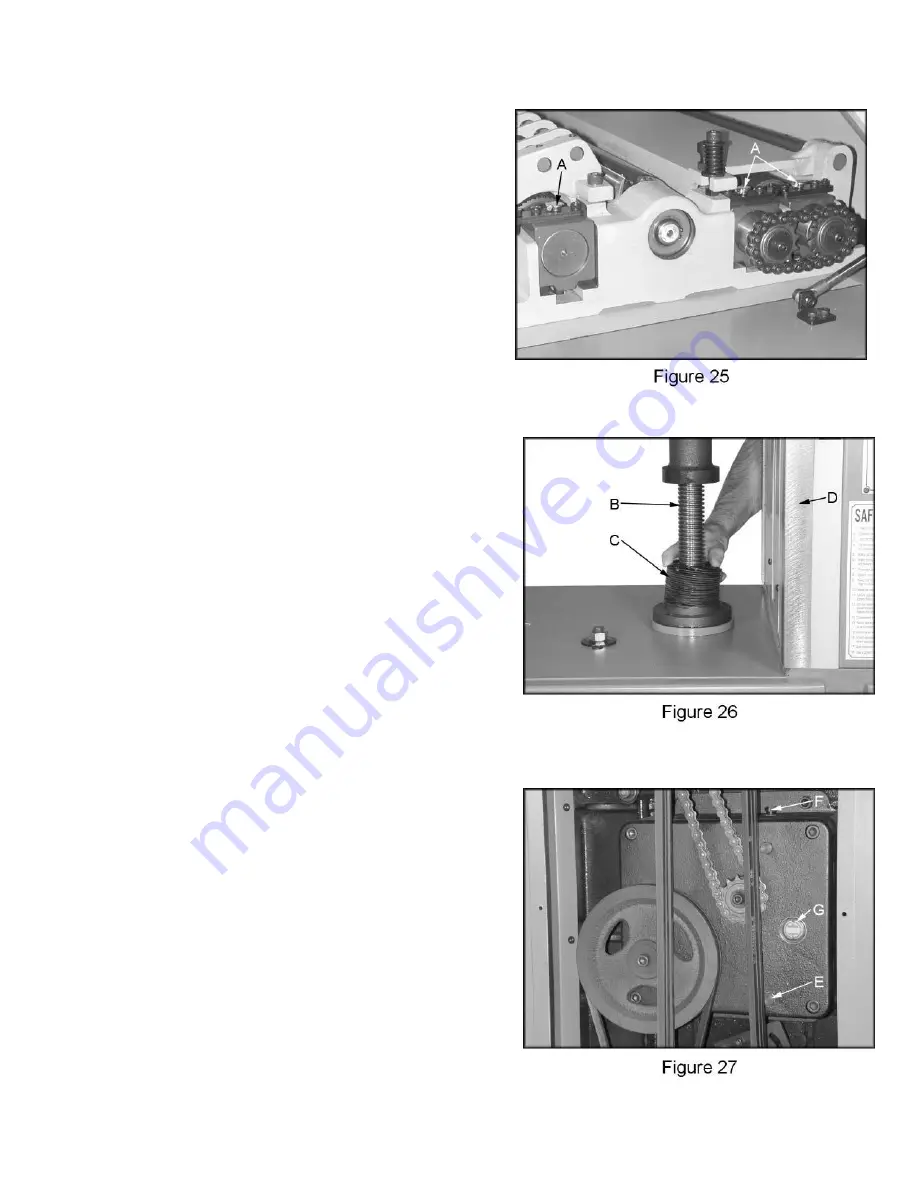

the six oil cups (A, Figure 25) weekly.

Lubricate the two table elevation screws (B,

Figure 26) as needed. Raise the table and

remove the two screws holding the top of

the accordion cover (C, Figure 26) in place.

Pull the cover down and lightly grease the

elevating screws, see Figure 26.

Use an oiled cloth to wipe the ways (D, Figure 26)

weekly.

Lubricate the chain system with an oiled cloth as

needed.

The gear box oil should be changed once a year.

Remove the drain plug (E, Figure 27) to drain the oil.

Refill the gear box with 60-90 weight gear oil through

the fill hole (F, Figure 27) until the sight glass reads

full. The sight glass (G, Figure 27) should be

checked periodically and oil added as necessary.

Summary of Contents for MPLAN25-10-1-0130

Page 17: ...16 PARTS DIAGRAMS...

Page 18: ...17...

Page 19: ...18...

Page 20: ...19...

Page 21: ...20...