7

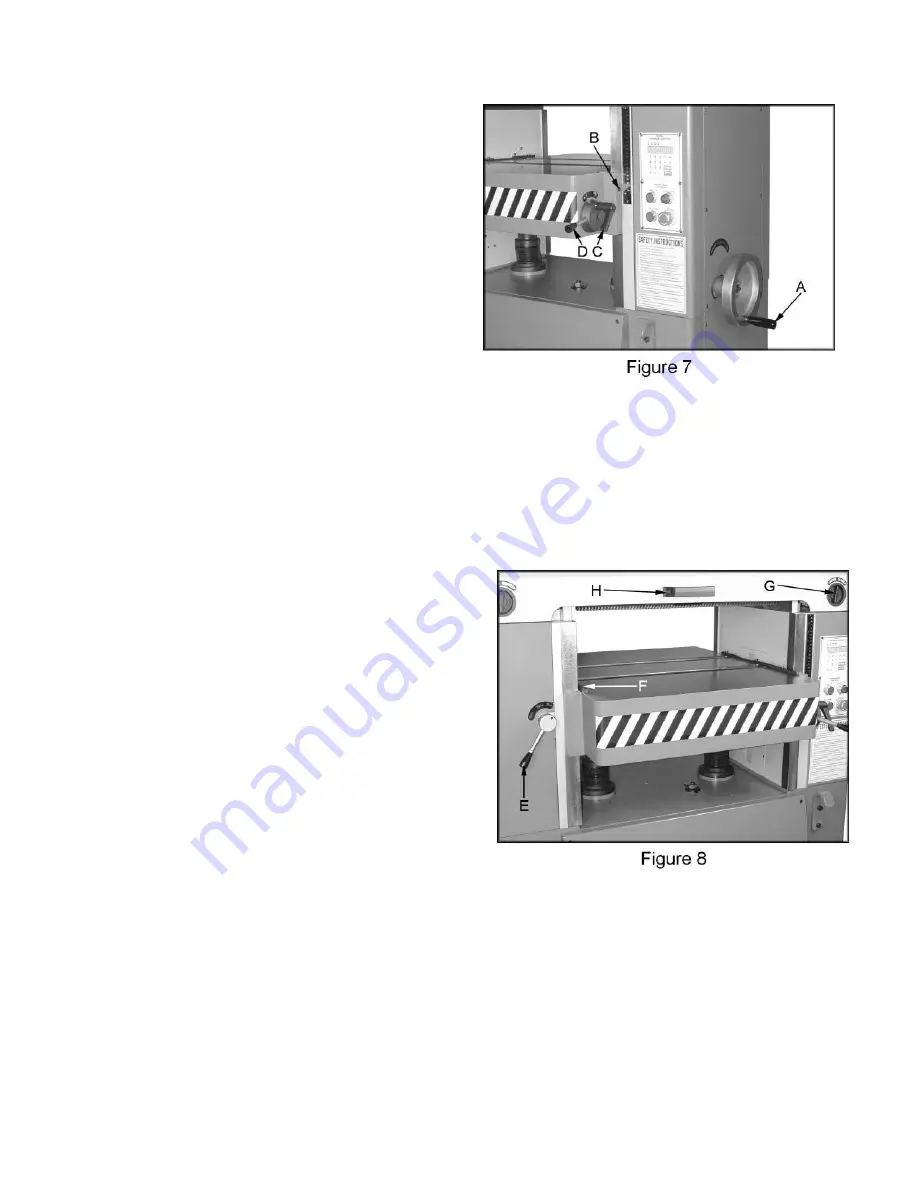

Raising and Lowering Table

Turn the handwheel A (Fig. 7) clockwise to

raise the table. One revolution equals 1/32”

or 0.03”.

Note: The handwheel is spring loaded.

Push in on the handwheel and rotate

until the pins engage the detents.

Adjusting Thickness Scale

1. Run a board through the planer and

measure the thickness of the planed

board with a pair of calipers.

2. Adjust the pointer B (Fig. 7) by loosening

the screw that holds it in place.

Note: This measurement should be the

same as digital readout.

Table Roller Adjustment

Loosen the handle C and move the table

rollers up, or down by raising, or lowering

the handle D. When you reach the desired

position tighten the handle (Fin. 7).

The rollers are usually set higher when

planning rough stock. When planning smooth

stock the table rollers should be set slightly

above, or flush with the table.

Changing Feed Rate

The planer has three selectable feed speeds

that feed stock at 20, 25 and 30 feet per

minute. To adjust speed, turn lever E (Fig. 8)

until it clicks into place. Change feed speed

only while the feed system is RUNNING!

Table Stop

The socket head cap screws F (Fig. 8) act as a stop

and prevent you from running the table into the

cutting and feeding assembly.

Opening Hood

Turn the locks G to open the hood. The hood will

open automatically. Use the handle H to shut

the hood (Fig. 8).

Summary of Contents for MPLAN25-10-1-0130

Page 17: ...16 PARTS DIAGRAMS...

Page 18: ...17...

Page 19: ...18...

Page 20: ...19...

Page 21: ...20...