V-BELT TENSION ADJUSTMENT

CONVEYOR BELT

After the machine has been in operation for a long time, the V-belt

The conveyor belt should always run at the center of the contact drum.If it

may become slightly loose. Should this occur, there will be an abnormal

approaches either to the left or right, adjustment is necessary. First check that

sound while the motor is running. Adjust the V-belt as follow.

the conveyor belt tension is correct. If the tension is too loose,adjust this first

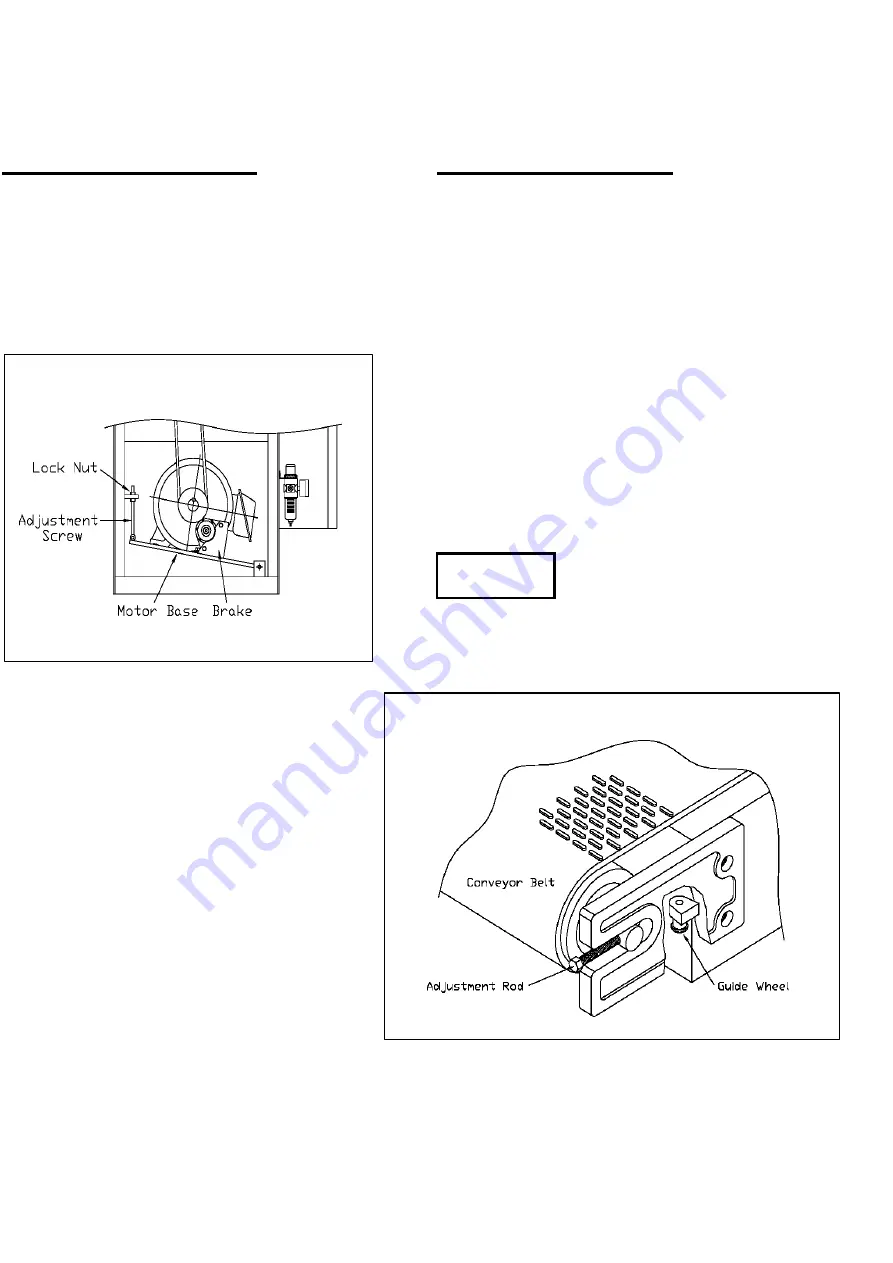

Figure 11: Slightly loose the lock unit that tightens the motor base, and

before you adjust the tracking.

turn the adjustment screw until correct tension is achieved.

See Figure 12

Re-tighted lock nut.

CONVEYOR BELT TENSION:

1. Disconnect the sander from the power source.

2. Remove from brake cover by removing the four screw.

3. Turn both adjustment rod clockwise equally to increase tension.

CONVEYOR BELT TRACKING:

1. Turn the conveyor belt "ON"

2. If the belt is tracking to the right side of the table, turn the right

adjustment rod clockwise.

3. If the belt us tracking to the left side of the table, turn the left

adjustment rod clockwise.

THE EDGE OF THE CONVEYOR BELT SHOULD JUST TOUCH THE

GUIDE WHEELS.

Figure 11

14

Figure 12

NOTICE !!

Summary of Contents for MSANWB43X75-2RK-25-0197

Page 2: ......

Page 12: ...MAJOR PARTS OF THE MACHINE 7...

Page 14: ...CONTROL PANEL FEATURES Figure 6 Figure 7 9...

Page 22: ...GENERAL ELECTRICAL DIAGRAM 37 1K SINGLE PHASE 17...

Page 23: ...18...

Page 25: ...20...

Page 27: ...22...

Page 29: ...24...

Page 31: ...26...

Page 33: ...28...

Page 35: ...30...

Page 37: ...32...

Page 39: ...ELECTRICAL PARTS 37 1K SINGLE PHASE 34...

Page 41: ...36...