11

SHEARTEC 2 CUTTERHEAD

WARNING:

Knife inserts are dangerously sharp.

Use extreme caution when inspecting,

removing or replacing knife inserts.

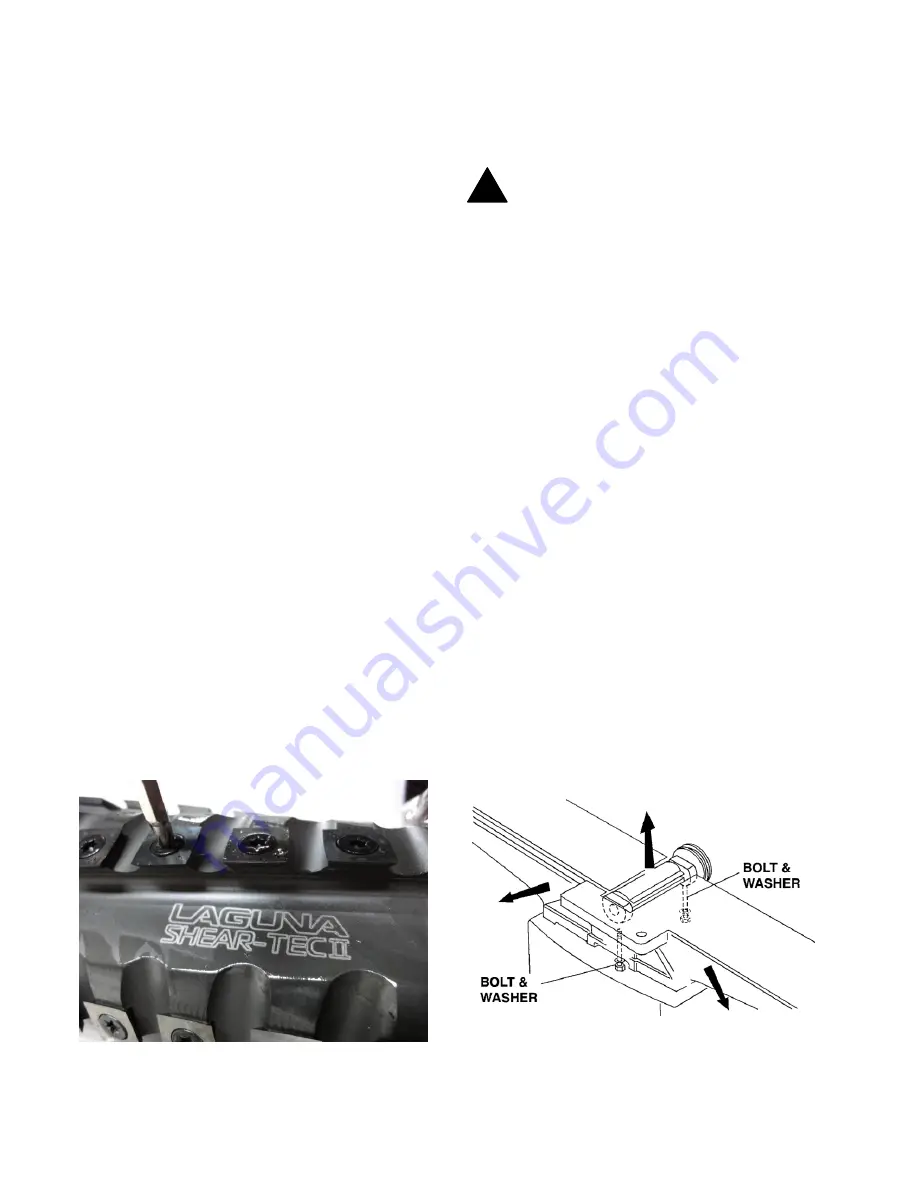

The knife inserts on the Jointer are four-sided.

When dull, simply remove each insert, rotate it

90° for a fresh edge, and re-install it. No further

adjustment is necessary. Use the two provided

torx wrench to remove the knife insert screw.

Use one of the torx wrenches to help hold the

cutterhead in Position, and the other to remove

the screw. See Figure 19A. It is advisable to

rotate all inserts at the same time to maintain

consistent cutting. However,

if one or more knife inserts develops a nick,

rotate only those inserts that are affected.

Each knife insert has an etched reference mark

so you can keep track of the rotati

ons.

IMPORTANT: When removing or rotating

inserts, clean saw dust from the screw, the

insert, and the cutterhead platform. Dust

accumulation between these elements can

prevent the insert from seating properly, and

may affect the quality of the cut.

Before installing each screw, lightly coat the

screw threads with machine oil and wipe off any

excess.

Securely tighten each screw which holds the

knife inserts before operating the jointer!

Make sure all knife insert screws are tightened

securely. Loose inserts can be propelled at high

speed from a rotating cutterhead, causing injury.

FIGURE

19A

CUTTERHEAD REMOVAL

If removal of the cutterhead is necessary, do

the following:

WARNING: Disconnect jointer from

power source.

1. Remove the entire fence assembly by

releasing lock handle and removing hex nuts

(see page 4) Lift the fence off the machine.

2. Loosen the bolts connecting the motor to the

motor mount and remove the drive belt from

cutter- head pulley (see page 4).

3. Lower

both

infeed

and

outfeed

tables

to

expose

the

cutterhead.

4. Remove

the

two

bolts

and

spring

washers

which

secure

the

cutterhead

to

the

base,

as

shown

in

Figure 19B

5. Remove

the

cutterhead

assembly,

with

studs

at-

tached,

by

lifting

cutterhead

straight

up

from

base.

The

belt

pulley

may

be

left

on

cutterhead

to

assist

in

raising

the

cutterhead.

6. Remove

pulley

and

both

bearing

housings

with

attached

studs

from

the

cutterhead.

NOTE:

You

may

wish

to

keep

on

hand

an

extra

cutterhead

in

order

to

maintain

shop

productivity.

7. When

mounting

new

cutterhead

to

base,

make

sure

the

curved

seats

of

the

base

are

cleaned

and

free of

dust

and

grease.

FIGURE 19B

!