18

knob will come on when INTELLISAND is

operating. (Fig. 11 a) When the load is decreased,

INTELLISAND will automatically increase the feed

rate to the pre-selected speed. INTELLISAND

does

not

engage when brush sanding or if drum sanding at

a slower RPM than recommended.

Setting Brush Depth of Cut/Contact

When a nylon or wire brush is worn and needs

changing, the bristles will either have fractured and

the brush head looks “bald” or the bristle length

has worn and the bristles are too short for effective

brushing.

When an abrasive or cloth brush is worn, the brushing

material will become smooth, or the brush will be

considerably smaller in diameter as compared to new.

Please call SuperMax Tools if you have any questions.

Brush life can vary considerably, due to RPM, contact,

type of brush, and material being brushed.

Some types of brush heads, some flatter brushes, for

example, will allow changing of the brush material by

the operator.

When using a wire brush for “distressing” wood,

slowing brush RPM, using light contact and a

moderate feed rate generally will give the best finish

and longest brush life. When using a wire brush on

metal, it is important to use a light contact of the

bristle tips.

Nylon Brushes.

If a nylon brush

becomes uneven dressing the tips of bristle brush to

maintain uniform brush wear will be a benefit.

Dressing Instructions:

Staple or glue a wide sheet of 60 grit sandpaper to

a 1/2” thick fla

t wood surface. Strips of narrow

sandpaper can also be used. Lower the brush so the

tips of the bristles contact the sandpaper by

1/32”.

Set

the conveyor speed to approximately 50% feed rate.

Pass the abrasive loaded board through the machine

until the brush fibers are sharp and even.

Setting Drum Depth of Cut

Determining the depth of cut is the most

IMPORTANT set-up procedure before operating as

a drum sander.

It may take some experimentation to

determine the proper depth of cut, given the variables

of abrasive grit, type of wood, and conveyor feed rate.

Practicing on scrap before sanding a project can be

beneficial.

A good rule-of-thumb when sanding is to place the

workpiece under the drum and lower the sanding

head until the workpiece contacts the drum, but the

drum can still be rotated by hand. When making

successive passes, lower the sanding head no more

than the thickness of the grit abrasive, I.e., 1/8-1/16

of a turn for 80 grit and less for finer grits.

Note:

one

revolution of the height adjustment handle moves the

sanding head approximately

1/16”.

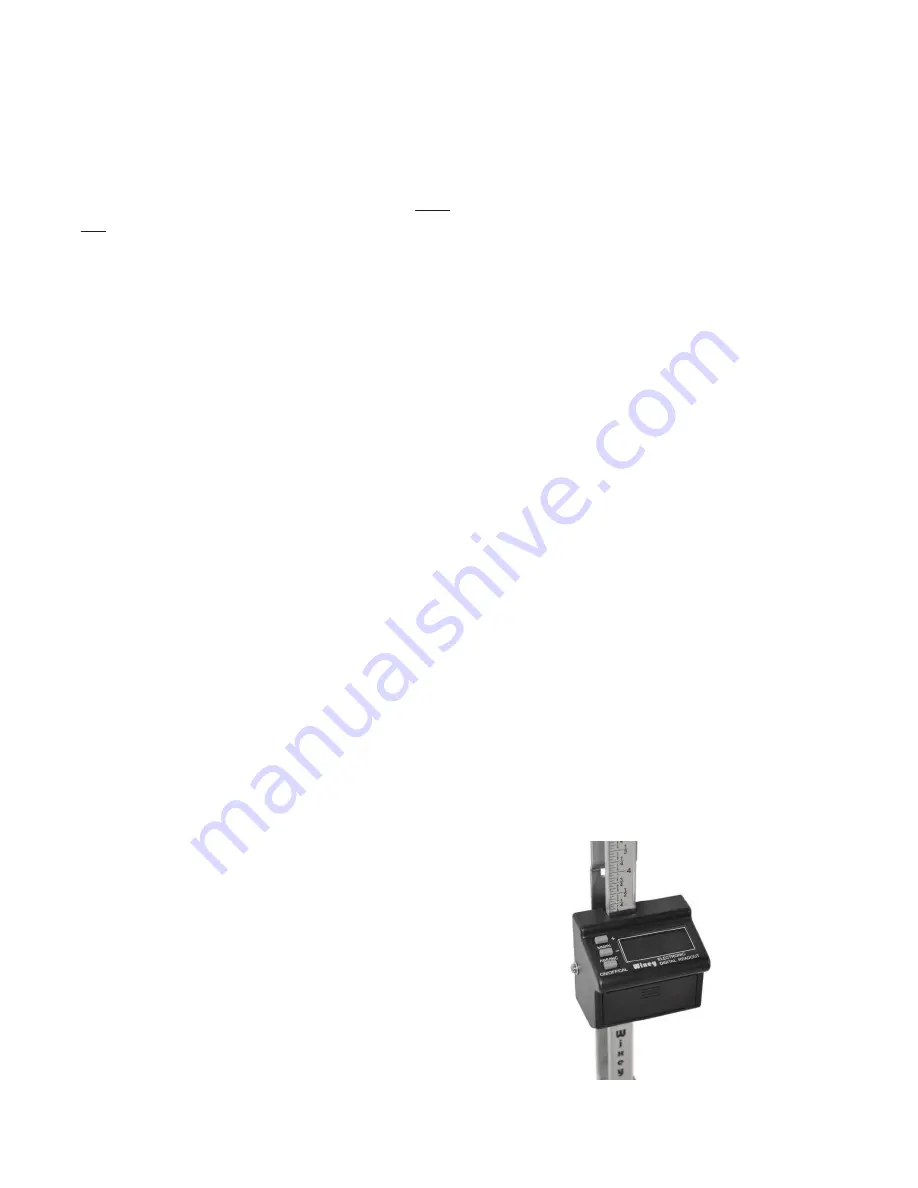

Depth Gauge Operation

The depth gauge (see Fig. 5) measures the distance

between the conveyor table and the bottom of the

sanding brush or drum. The sanding head must

be parallel to the conveyor bed surface. To calibrate

the depth gauge, loosen the two screws holding the

scale. Lower the brush or sanding head (with abrasive

installed) until the head touches the conveyor belt.

Slide the scale to align with the pointer at the “0”

mark. Tighten the two screws holding the scale. An

optional DRO (digital read out) for depth is available.

Fig. 12. This offers the most precise reading of sanded

thickness and allows for accurate repeatability of a

thickness. Great when making parts that must be an

exact thickness or when matching a thickness.

To operate, turn ON and select standard inch

“in”

or

metric millimeter

“mm”.

Lower drum, with abrasive

installed, until it touches the conveyor belt. Press

“zero” button to calibrate.

Fig. 12 Optional DRO

Summary of Contents for SuperMax 19-38 Combo

Page 1: ...19 38 Combo Brush Drum Sander Owner s Manual Lagunatools com SKU 219383...

Page 31: ...31...

Page 34: ...34 34...

Page 36: ...36...

Page 39: ...39...