25

12-b

12-c.

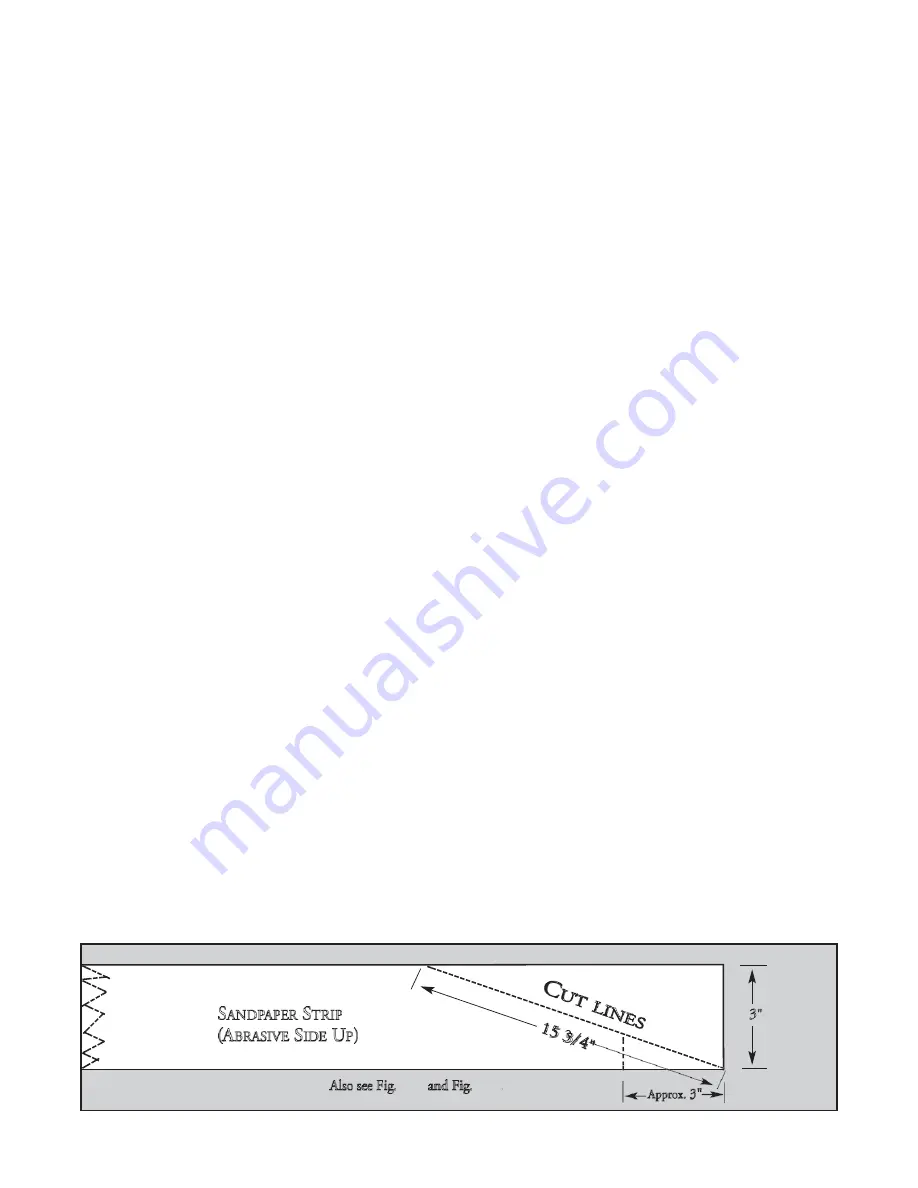

Wrapping Abrasive Strips

Note: When using Pre-Marked

™

or Pre-Cut

™

abrasives, not all of the steps below are necessary.

Proper attachment of the abrasive strip to the drum

is critical to achieving top performance from your

SuperMax Tools drum sander. Abrasive strips do not

have to be pre-measured. The end of the roll is first

tapered and attached to the left (outboard) side of the

drum. Then the strip is wrapped around the drum,

and the second taper is made for attachment to the

right (inboard) side of the drum. To attach a strip to

the drum, follow the procedure below.

1.

Mark and cut a taper at one end of the roll as

shown in Fig. 16a. Because the tapered end should

use most of the left (outboard) slot width, its end

must be trimmed (Fig. 16B and 16C). Raise the

clip lever on the left (outboard) side of the drum

(Fig. 16D). Insert the tapered end through the slot

and into the fastener so that it uses most of the

width of the slot. Release the clip lever to securely

hold the strip end in the fastener.

2.

Wrap the strip around the drum, being careful

not to overlap the windings. The tapered cut of

the strip end should follow the edge of the drum.

Continue to wrap the abrasive in a spiral fashion by

rotating the drum with your left hand and guiding

the strip with your right hand (Fig 16E). Successive

windings of the strip should be flush with previous

windings without any overlap.

3.

Mark the trailing end of the strip where it crosses the

right (inboard) end of the drum (Fig. 16F). From

this point, cut a taper as was done with the starting

edge of the strip. (The taper on the remaining roll

can be used as the taper for the starting edge of the

next strip to be cut.)

4.

With the trailing edge of the strip properly cut,

rewrap the drum and insert the tapered end

through the slot in the right (inboard) end of the

drum. Insert the tapered end into the inboard take-

up fastener. Pull up on the clip lever to open the

clip, and pull the take-up lever to the top as shown

(Fig. 16G). After inserting the strip end, release the

clip lever by moving your index finger toward the

drum slot. This allows the clip to retain the abrasive

while holding the take-up lever in an

“up”position.

5.

The take-up fastener is designed to automatically

take up any slack caused by stretching of the

abrasive strip.

Important: Position the abrasive

strip in the slot with sufficient room between the

inside of the slot and the tapered end of the strip to

allow it to be pulled into the drum as needed (Fig.

16H). Note that not leaving enough space between

the strip and the inside of the slot will prevent the

take-up fastener from operating properly.

6.

The abrasive strip may stretch enough in use to allow

the take-up lever to reach its lowest position so it no

longer is able to maintain tension on the strip (Fig.

16I). If this occurs, it will be necessary to reset the

take-up lever by raising it, pushing the strip end into

the slot, and then releasing the clip lever.

Note:

A sandpaper cleaning stick may be used to

remove deposits and help extend sandpaper life. To

use, operate the sanding drum with the dust cover

open. (

Caution:

For your own safety, always wear eye

protection while performing sandpaper cleaning, and

take all precautions to avoid any contact of hands or

clothing with uncovered drums.) Hold the cleaning

stick against the rotating drum and move it along the

drum surface. It is good procedure to use a shop brush

to remove any cleaning stick crumbs from the drums

before resuming sanding operations.

Fig. 16 Marking and cutting taper on strip.

S

ANDPAPER

S

TRIP

(A

BRASIVE

S

IDE

U

P

)

Approx.

3"

Also see Fig.

16-b

and Fig.

16-c

3

"

Summary of Contents for SuperMax 19-38 Combo

Page 1: ...19 38 Combo Brush Drum Sander Owner s Manual Lagunatools com SKU 219383...

Page 31: ...31...

Page 34: ...34 34...

Page 36: ...36...

Page 39: ...39...