-4-

www.igmtools.com

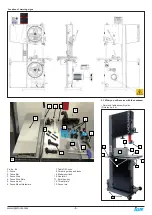

The bandsaw does not have many parts. The

major parts are discussed in this manual. If you

are not familiar with the bandsaw, take the time

to read this section and become familiar with

the machine.

1. Tension indicator/window

Tension indicators are designed to indicate

the compression of a spring. As a rule, the

greater the spring compression, the greater

the tension on the blade. The tension scale

does not register until the blade is relatively

taut and is located on the inside of the body of

the bandsaw. The tension scale is a general

reference and not a rule. It is visible with the

upper door closed by looking through the

tension indicator window.

2. Switch

To start the machine press the “I” button on

the start stop switch. To shut off the machine

press the “O” on the start stop switch. When

the safety switch is pressed it stops the power

to the motor. To reset it, twist and it will pop out

and allow power to be supplied to the motor.

.

3. Motor

The bandsaw is supplied with a 2,2kW, 400V

motor. It drives the lower flywheel through a

drive belt.

4. Frame

The frame of the bandsaw is a U-shaped frame,

which houses all the parts of the machine.

This is the heart of the bandsaw and has to be

very rigid, as it takes the strain of the blade

being tensioned.

5. Blade tension handle

The blade tension handle moves the blade

tension and tilt assembly vertically. The vertical

action compresses a spring that ensures

that the blade tension is constant and will

not change dramatically as the blade length

increases due to the heat generated by the

cutting action.

6. Blade tracking window

There is a blade tracking window on the side

of the frame that allows the edge of the upper

flywheel to be viewed. This allows the tracking

of the blade to be achieved with the door

closed.

7. Cast iron table

The table supports the work piece and can tilt

(-6 degrees to +45 degrees) to produce cuts at

various angles. It has a groove to the right-hand

side of the blade, which is used to guide the

miter gauge. In the center there is a table insert

which the blade passes through. Should the

blade wander off center, this table insert will

protect the blade from damage, as it is soft and

should not damage the blade. The table also

supports the adjustable fence, which is used for

parallel cuts. There is a nut and bolt that joins

both sides of the table and stops the table from

warping. The nut and bolt must always be fitted

in the table and only removed when removing

or fitting a blade.

8. Blade guide adjustment hand wheel

The upper blade guides are attached to the

blade guide shaft. The shaft is vertically

adjustable with a hand wheel. The guides

should be adjusted so the guides are just

above the wood being cut. This gives the blade

maximum stability and is also the safest way to

operate the bandsaw.

9. Blade guides

There are two sets of blade guides, one above

and one below the table. The function of the

guides is to give the blade stability and ensure

that the blade movement left/right, forward/

back is kept to a minimum. The guides above

the table are fitted to a shaft that has vertical

adjustment. The upper guides are adjustable so

that the guides are held just above the job being

cut. This gives the blade the maximum amount

of stability and also keeps the amount of blade

that is exposed to a minimum. The guides have

ceramic inserts that can be adjusted for almost

zero clearance.

10. Rip fence assembly

The rip fence assembly consists of a guide rail,

cast knuckle, fence attachment casting, rule

and a high-low fence. The guide rail is attached

to the table side. It guides the fence assembly

across the table. The cast knuckle slides on the

guide rail and is lockable in any position to

suit the width of cut. The fence attachment

casting is attached to the cast knuckle with

three screws that when loosened allow the

fence to be adjusted for drift. The fence is

attached to the fence attachment casting with

two studded knobs that allow the fence to be

adjusted laterally across the table to suit the

job being cut. The fence can be fitted in the low

position or the vertical (7 1/4“ height) position.

There is a rule that is fitted to the side of the

table and can be used as a quick guide on the

distance that th

The Fence Stop can be used for non through

cuts and can be set on any length of the fence

with the quick release handle.”e fence is from

the blade.

Note

. The rule will have to be adjusted each

time the fence is adjusted for drift, as this will

change the distance the fence is from the blade.

11. Dust ports 100 mm

The bandsaw produces a lot of sawdust, so

extraction is very important. This is achieved by

connecting a 100mm dust extraction hoses with

a minimum capacity of 1699 m

3

/h to the two

dust ports located at the back of the machine.

The stronger the suction from the dust collector,

the better for you and the machine.

12. Quick-release blade tension lever

There is a quick-release tension lever at the

back of the bandsaw. The lever is a convenient

way of quickly releasing the tension on

the blade and speeds up blade change

dramatically.

13. Blade-tracking knob

The blade-tracking knob is located at the back

of the bandsaw and is used to adjust the blade

tracking. The knob must be locked once the

adjustment is completed.

14. Optional mobility kit

The optional mobility kit is fitted to the base of

the bandsaw and consists of two fixed wheels

at the front of the bandsaw and a swivel wheel

at the back of the band saw. The swivel wheel

is activated and deactivated with a foot lever.

With the swivel wheel deactivated, the bandsaw

sits on two rubber feet.

15. Optional light

The optional light is fitted with four screws

through pre-drilled holes at the top of the

bandsaw. The bandsaw is provided with a 220V

socket that the light can be connected to.

16. Blade guide shaft lock

The upper blade guide is fixed to the blade

guide shaft, which is vertically adjustable. Once

the guides have been adjusted vertically, the

shaft is locked in position with the lock knob.

17. Flywheel

The blade is suspended over two wheels that

are covered with rubber called a „tire“. The tire

cushions the blade and protects the teeth from

coming in contact with the metal of the flywheel.

The lower wheel is the drive wheel and is

attached to the motor with a rubber drive belt.

The lower flywheel powers the blade and pulls

the blade down through the work piece. The

top wheel has two functions. One function is to

balance or track the blade on the wheels, and

the second one is to tension the blade. Both

functions are adjustable.

18. Brake

The bandsaw is provided with a brake that is

operated by applying the foot pedal. When the

foot pedal is applied, the power is removed

from the motor and the flywheel is slowed by

the disc break.

Rubber feet

Swivel wheel assembly

Disc break on flywheel

Emergency

stop button

Start / Stop buttons